Choosing the right material is one of the most critical steps in automotive plastic injection ...

How to Select the Best Plastics for Injection Molded Automotive Parts

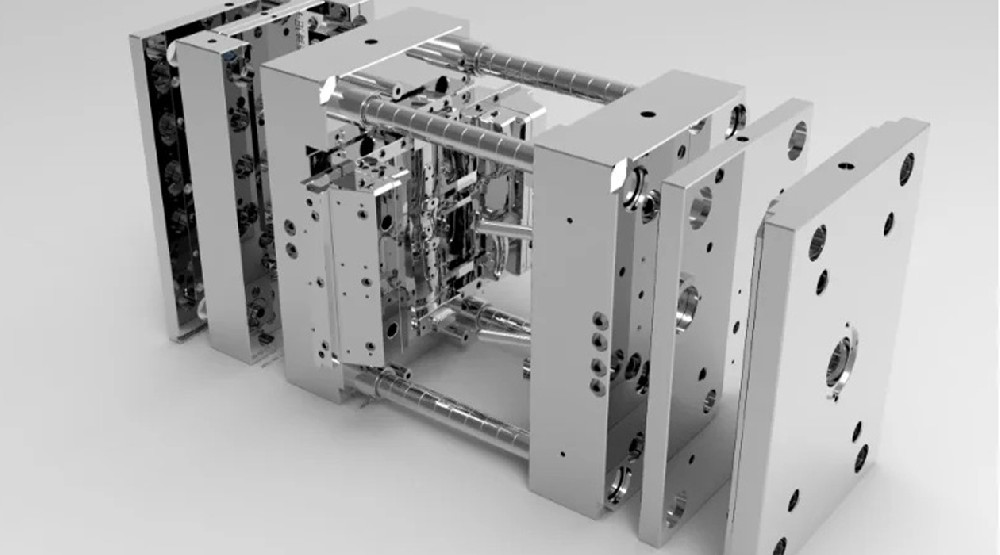

Choosing the right material is one of the most critical steps in automotive plastic injection molding. From interior trims to structural brackets and under-the-hood components, every resin directly impacts durability, dimensional stability, heat resistance, and overall part performance. As the automotive industry moves toward lightweight design, electric mobility, and integrated assemblies, selecting the correct material for injection molded automotive parts has become more essential than ever.

This guide provides a practical and comprehensive overview of the most widely used materials in automotive injection molding, helping engineers and manufacturers make informed decisions for high-quality and cost-effective production.

Why Material Selection Matters in Automotive Injection Molding

Automotive parts operate in demanding environments where materials are exposed to:

Constant vibration

Temperature changes ranging from −40°C to 150°C

Oils, fuels, cleaners, and chemical exposure

UV radiation

Tight tolerance and dimensional accuracy needs

Automotive safety and regulatory requirements

A suitable material ensures long-term performance, while a poor choice may cause warpage, cracking, deformation, or failure over time. Therefore, material selection is not only a technical decision—it is fundamental to the success of automotive plastic injection molding projects.

Most Common Materials Used for Injection Molded Automotive Parts

Below are the core materials used across modern automotive manufacturing.

Polyamide (PA6 / PA66)

Ideal for: High-strength structural parts & under-the-hood components

Polyamide (nylon) is among the most widely used materials in automotive injection molding. When reinforced with glass fiber, PA offers exceptional stiffness, strength, and thermal stability.

Advantages:

High mechanical strength

Excellent fatigue and impact resistance

Good oil and chemical resistance

Suitable for elevated temperatures

Limitations:

High moisture absorption

Requires proper drying before molding

Typical Applications:

Engine covers

Air intake manifolds

High-strength brackets

Cooling system parts

Polypropylene (PP)

Ideal for: Lightweight interior components

PP is one of the most versatile and cost-effective materials for injection molded automotive parts, especially in interior applications.

Advantages:

Lightweight and low density

Excellent chemical resistance

Good impact strength (PP-EPDM blends)

Highly recyclable

Limitations:

Limited temperature resistance

Requires UV stabilizers for outdoor exposure

Typical Applications:

Interior trims

Door panels

Instrument panel elements

Battery casings

ABS / PC-ABS

Ideal for: High-impact interior parts with aesthetic requirements

ABS is known for its strong impact resistance and good surface finish. PC-ABS blends offer enhanced heat resistance suitable for parts requiring appearance + performance.

Advantages:

Excellent toughness

Stable dimensions

Premium surface finish

Good moldability

Typical Applications:

Dashboard components

Pillar covers

Center console parts

Electronic housings

Polyoxymethylene (POM)

Ideal for: Precision moving mechanisms

POM (acetal) is a top choice for applications requiring low friction, high dimensional stability, and precision.

Advantages:

Very low friction

Excellent wear resistance

High stiffness

Resistant to fuels and chemicals

Typical Applications:

Gears & actuators

Seatbelt systems

Lock mechanisms

Hinges and clips

Polycarbonate (PC)

Ideal for: Optical-grade & high-impact automotive components

PC is widely used in automotive lighting systems and transparent elements.

Advantages:

High transparency

Outstanding impact strength

Heat-resistant grades available

Typical Applications:

Light covers

Display lenses

EV dashboard components

Thermoplastic Polyurethane (TPU)

Ideal for: Flexible, durable components

TPU offers excellent elasticity, abrasion resistance, and durability.

Applications:

Seals & gaskets

Cable jackets

Soft-touch interior parts

High-Performance Plastics (PPS / PEEK)

Ideal for: High-temperature EV & engine components

For extreme environments, PPS and PEEK deliver unmatched mechanical, thermal and chemical stability.

Applications:

EV battery system components

High-temperature connectors

Powertrain parts

How to Select the Right Material for Injection Molded Automotive Parts

Material selection depends on these factors:

Mechanical Requirements

Strength, impact resistance, stiffness, and fatigue behavior.

Thermal Performance

Consider continuous operating temperature and peak heat exposure.

Chemical Environment

Exposure to oils, fuels, coolants, or cleaning agents.

Dimensional Stability

Critical for gears, connectors, and precision mechanisms.

Weight Optimization

PP and glass-filled PA are leading choices for lightweighting.

Cost & Production Volume

Balance between performance and budget.

Aesthetic & Surface Requirements

ABS and PC-ABS offer excellent finishes for visible interior parts.

Quick Material Selection Matrix

| Requirement | Recommended Material |

| Structural load-bearing | PA6/PA66 (GF) |

| High-temperature use | PPS / PEEK / PA66 |

| Interior trim | PP or ABS / PC-ABS |

| Precision gears | POM |

| Flexible / soft-touch | TPU |

| Transparency | PC |

Looking for Reliable Hot Runner Temperature Controllers for Automotive Injection Molding?

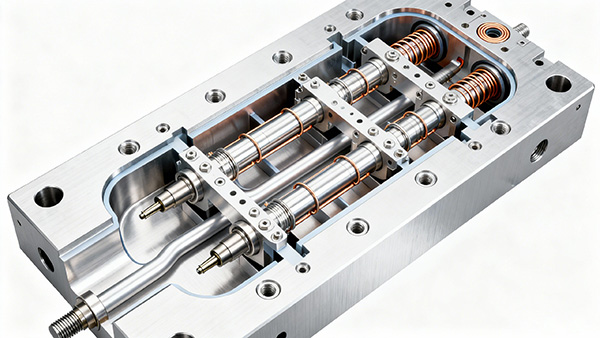

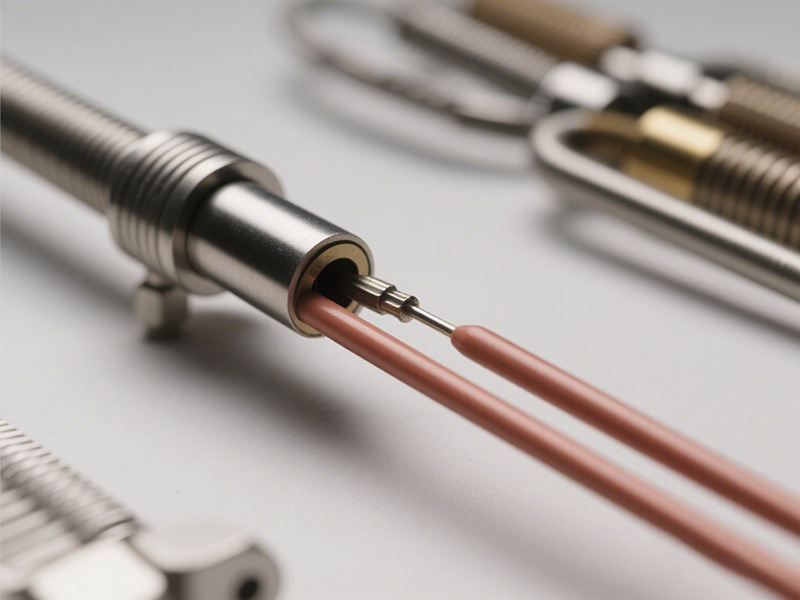

For stable, efficient production of injection-molded automotive parts, precise temperature control is essential—especially when running multi-cavity molds, high-temperature engineering plastics, and large-volume automotive projects.

At CNTO Power (https://www.cntopower.com/), we provide advanced, reliable hot-runner temperature-control solutions specifically designed for automotive applications.

Our Key Products Include:

Precision PID-controlled units for demanding materials

Why Automotive Manufacturers Choose CNTO Power:

Ultra-fast heat-up and stable temperature control

Consistent zone balancing for multi-cavity production

Reduced mold setup and tuning time

Improved cycle consistency & defect reduction

Designed for long-term industrial use

If you want to upgrade your mold performance, enhance part quality, or stabilize your automotive injection molding production, our engineering team is ready to help.

Explore our full range of hot runner temperature controllers: https://www.cntopower.com/

Contact us today for technical support or custom solutions.