Choosing the right material is one of the most critical steps in automotive plastic injection ...

A Complete Guide to Hot Runner Molds: Advantages, Disadvantages, Key Technical Factors, and Application Fields

Introduction

As injection molding technology continues to advance, hot runner molds have become a mainstream solution in global manufacturing. From thin-wall packaging to medical devices and consumer electronics, industries increasingly rely on hot runner systems to shorten cycle time, reduce material waste, and achieve high-precision results.

Based on decades of industrial experience and practical application, this article provides a systematic and expanded guide covering:

Advantages and disadvantages of hot runner molds

Key technical factors affecting hot runner performance

Compatibility with materials and product sizes

Industrial applications across multiple sectors

Whether you are a mold manufacturer, injection molding engineer, or project manager, this guide will deepen your understanding of hot runner technology and help you make better decisions for production optimization.

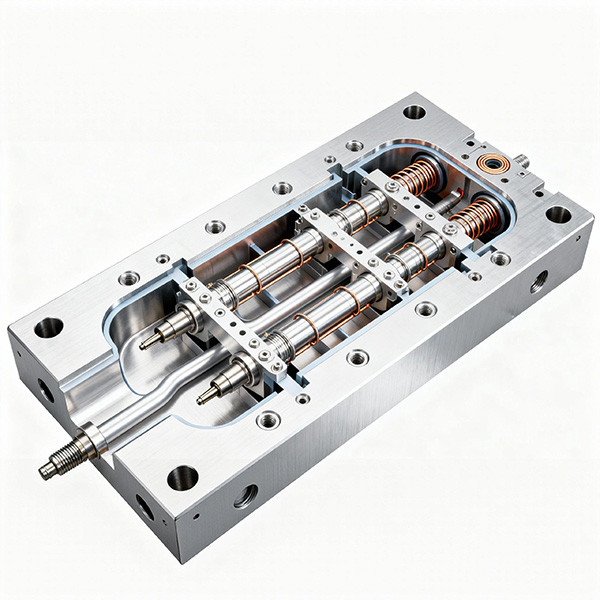

Advantages of Hot Runner Molds

Hot runner molds are widely used in industrially developed countries because they deliver significant performance and economic benefits. The following sections expand each advantage in detail.

Shorter Molding Cycle

One of the most recognized benefits of hot runner systems is the ability to reduce cycle time dramatically.

Because there is no cold runner to cool and solidify, the molded part can be ejected immediately after solidification.

Key points:

Thin-wall parts produced with hot runner molds often achieve cycle times of below 5 seconds.

Faster cycles directly translate into increased throughput and cost savings.

For high-volume production (e.g., packaging, caps, medical consumables), cycle-time reduction brings exponential economic benefits.

In industries where every second counts, hot runner technology can significantly increase daily or annual production output.

Material Savings and Reduced Waste

Pure hot runner systems eliminate cold runners, resulting in:

No sprue waste

No need for grinding or reprocessing

No contamination risk from recycled material

This is especially important when processing expensive engineering plastics, such as PC, POM, PBT, LCP, PA6/PA66, PEI, PMMA, and more.

Historically, hot runner manufacturers grew rapidly during periods of rising oil and resin prices, because reducing raw material consumption directly improved competitiveness and profitability.

Improved Product Quality and Consistency

Hot runner systems precisely control melt temperature along the entire flow path.

Advantages include:

Stable, uniform melt reaching every cavity

Better part-to-part repeatability

Minimal gate vestige

Lower residual stress after demolding

Reduced warpage and deformation

Many globally recognized products are manufactured with hot runner molds due to strict quality requirements—for example:

MOTOROLA mobile phone components

HP printer internal parts

DELL laptop housings and functional components

High-precision injection molding heavily depends on hot runner consistency.

Reduced Post-Processing and Improved Automation

With hot runner systems, the molded part is a finished product:

No need to trim gates

No need to recycle cold runners

No manual handling or sorting required

This greatly simplifies downstream operations and enables full automation.

Many manufacturers integrate hot runners with:

Robots

Conveyor systems

Vision inspection

Automated packaging

The result is a highly efficient production cell with fewer operators and stable output.

Expanded Processing Capabilities

Hot runner technology is the foundation of many advanced injection molding processes, including:

PET preform molding

Multi-color injection (multi-shot molding)

Multi-material molding (hard/soft combinations)

Stack molds

Sequential valve gate molding

Co-injection

Without hot runners, these processes would be difficult or impossible to achieve.

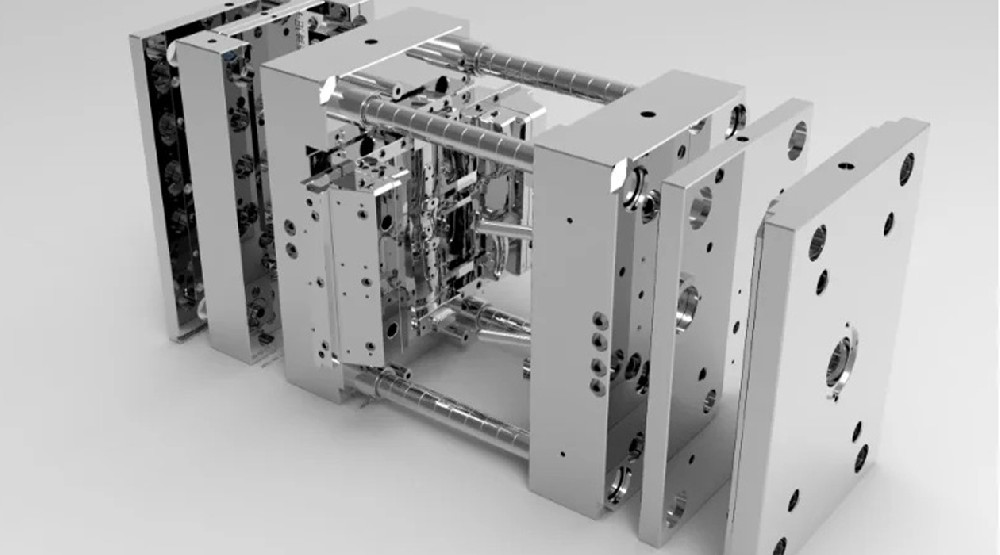

Disadvantages of Hot Runner Molds

Despite numerous benefits, manufacturers should also understand the limitations of hot runner systems.

Higher Initial Tooling Cost

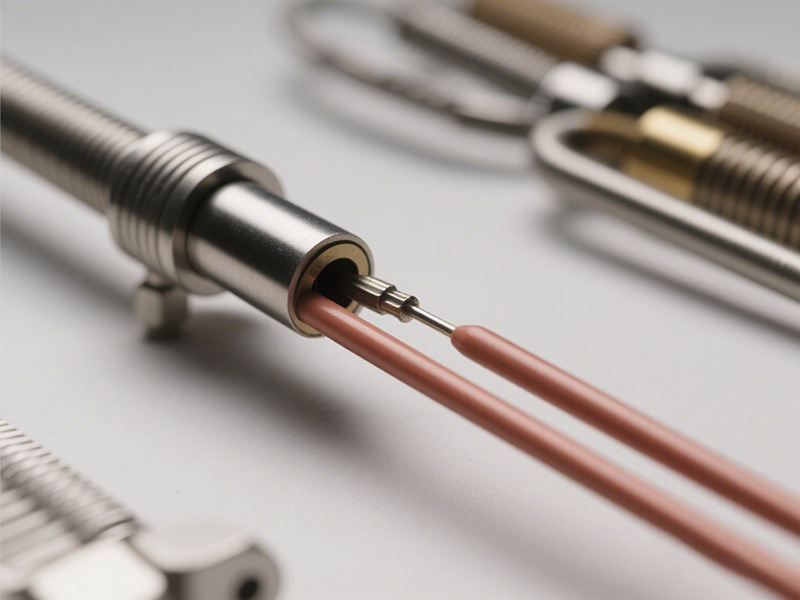

Hot runner components—manifolds, heaters, controllers, nozzles, and valve gates—are expensive.

This results in:

Higher mold cost

Longer mold manufacturing lead time

Reduced economic viability for low-volume projects

In many developing regions, the high upfront cost remains one of the main barriers preventing widespread adoption.

High Requirements for Mold Manufacturing Precision

A hot runner system must integrate seamlessly with the mold.

If tolerances or assembly conditions are not precise, serious issues may occur:

Plastic leakage inside the manifold pocket

Heater burnout

Misalignment between gate inserts and nozzle tips

Reduced product quality

Unexpected production downtime

Precision machining, strict assembly procedures, and experienced toolmakers are essential.

More Challenging Operation and Maintenance

Compared with cold runner molds, hot runner systems:

Require more careful temperature regulation

Have more components that may fail

Are sensitive to improper startup/shutdown procedures

Are less forgiving of molding mistakes

New users typically need time to accumulate operating experience to avoid damaging components or causing production stoppages.

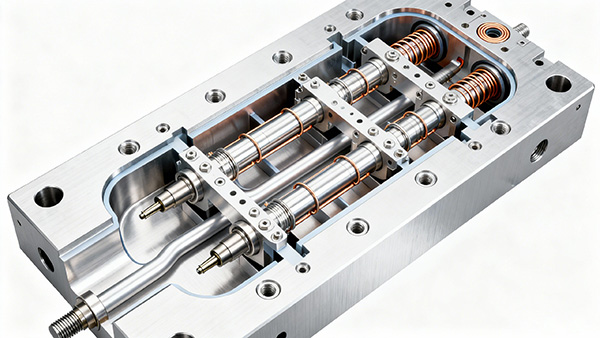

Key Technical Factors for Successful Hot Runner Applications

To ensure a successful hot runner project, the following technical factors must be monitored closely.

Melt Temperature Control

Temperature control is the core of hot runner performance.

Common issues caused by poor temperature control:

Poor gate quality when using thermal-gate (hot-tip) systems

Valve pin not closing smoothly in valve gate systems

Inconsistent filling and part weight differences in multi-cavity molds

Best practices:

Choose multi-zone temperature controllers

Use thermocouples placed accurately

Ensure manifold and nozzles maintain uniform heating

Optimize start-up and shut-down procedures

Stable melt temperature is essential for consistent molding results.

Melt Flow Balance Control

Flow imbalance is another major challenge in hot runner design.

Problems caused by poor flow balance:

Short shots

Over-packing

Excessive flash

Cavity-to-cavity weight variations

Key considerations:

Avoid excessively small runners (causing high pressure loss)

Avoid overly large runners (causing material degradation due to long residence time)

Ensure gates open synchronously

For family molds, balance flow paths based on part weight ratio

Use CAE simulation tools like Moldflow or Moldex3D for manifold design optimization

Proper flow balancing ensures stable productivity and consistent part quality.

Application Scope of Hot Runner Molds

Hot runner molds are highly adaptable and can be used across many domains.

Compatible with a Wide Range of Plastics

Hot runners can process almost all injection-moldable materials, including:

PP

PE

PS

ABS

POM

PC

PA6/PA66

PVC

PET

PMMA

LCP

PEI

ABS/PC blends

Any material suitable for cold runner injection molding can be processed with a hot runner system.

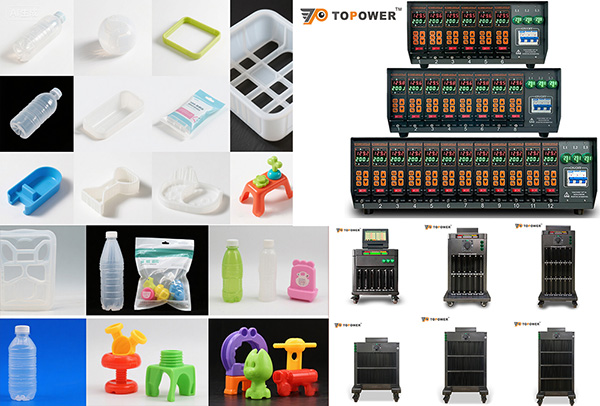

Widely Used Across Multiple Industries

Hot runner molds are now common in:

Electronics

Automotive

Medical devices

Toys

Household goods

Packaging

Industrial components

Office equipment

Construction and architectural hardware

As automation and high-precision manufacturing expand, hot runner adoption continues to grow worldwide.

Conclusion

Hot runner molds deliver major advantages in efficiency, quality, material savings, and automation compatibility, making them an essential technology for modern injection molding.

Although the initial cost and operational complexity are higher compared with traditional cold runner systems, the long-term benefits—especially for high-volume or high-precision production—are significant and transformative.

For manufacturers seeking to improve competitiveness, reduce waste, and adopt advanced molding processes, hot runner technology is a strategic investment worth considering.