The Role of Zones in a Hot Runner Control SystemIn injection molding, the hot runner control s...

The Direct Impact of Temperature Controller Parameter Optimization on Product Quality

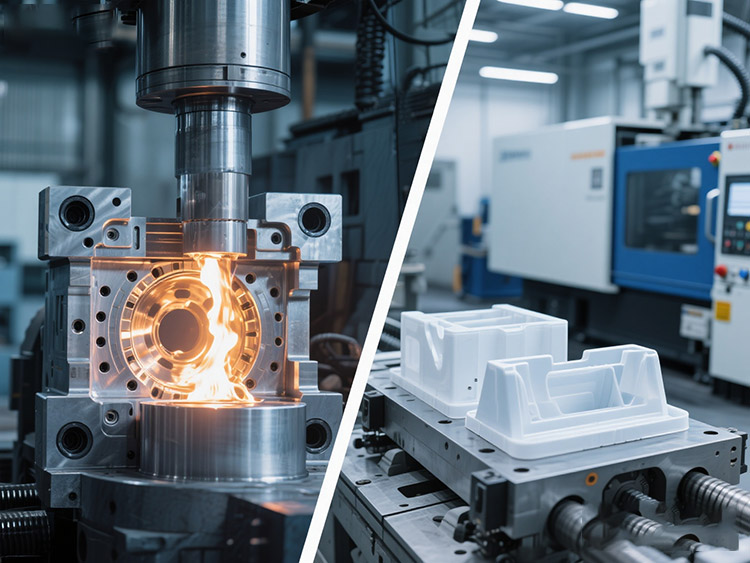

In a hot runner system, the settings of the temperature controller not only determine the operating state of the heater but also directly affect the flowability of the plastic melt, filling efficiency, and surface quality of the finished product. Scientifically adjusting and optimizing temperature controller parameters is a crucial means of reducing scrap rates and enhancing production stability.

Temperature Accuracy and Quality Stability

Excessively high temperature: Excessive melt flow may lead to defects such as flow marks, shrinkage, and reduced surface gloss.

Excessively low temperature: Poor melt flow and insufficient filling may result in issues like porosity and short shots. Precisely setting the temperature of each heating zone ensures uniform melt flow throughout the runner and mold, thereby producing products with smooth surfaces and dense interiors.

Zone Temperature Control and Temperature Gradient Optimization

In multi-cavity molds or complex runner systems, different regions require different temperatures. Reasonably setting the temperature gradients of each heating zone can prevent local overheating or uneven cooling, reducing issues such as warping and dimensional deviations, and ensuring consistent filling of each cavity.

Response Speed and Fluctuation Control

High-response-speed temperature controllers can quickly adjust according to temperature changes, reducing batch variations caused by temperature lag and maintaining product consistency during large-scale production.

Control During the Cooling Stage

Optimizing temperature controller parameters involves not only heating but also cooling:

Too rapid cooling may cause stress cracks or deformation.

Too slow cooling: may result in surface unevenness or cold shuts. Precise control of the cooling process helps improve appearance and dimensional stability.

Energy Efficiency and Cost-Effectiveness

Appropriate temperature control parameters can reduce overheating, lower power consumption and heat loss, achieve energy savings and cost reduction, while maintaining product quality.

Material Property Matching

Different plastic raw materials have varying sensitivities to temperature, for example:

High-melting-point materials (PPS, PEEK) require higher temperature settings.

Low-melting-point materials (PS, PVC) should have lower temperatures to avoid overheating. Adjusting parameters based on material properties can enhance product performance and durability.