When planning plastic part production, companies often face a critical decision: small run injection...

Applications and Advantages of Hot Runner Temperature Controllers in the Personal Care Industry

Precision Temperature Control for High-Quality Personal Care Manufacturing

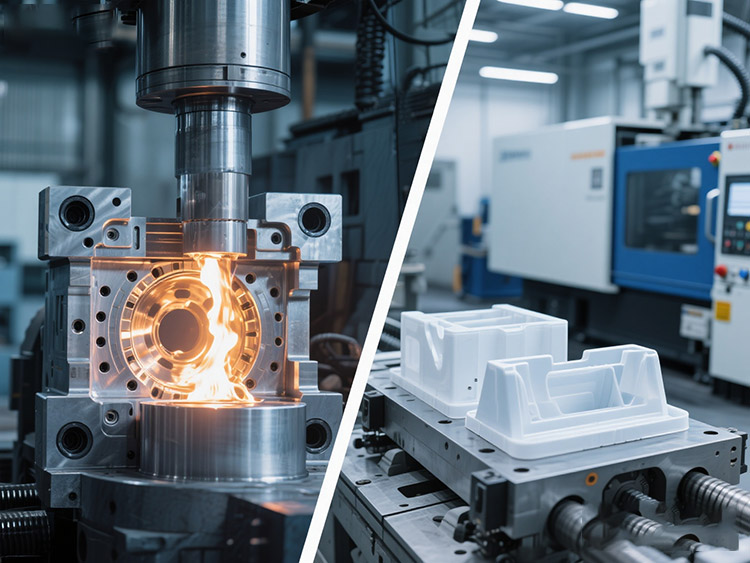

As consumers demand higher-quality and more aesthetically pleasing personal care products, brands and OEMs are seeking efficient and stable injection molding solutions. Hot runner systems—especially high-performance temperature controllers—have become essential tools for ensuring precision molding and perfect product appearance.

Topwer offers high-precision hot runner temperature controllers designed to meet the high visual, high-efficiency, and eco-friendly standards of the personal care industry—helping customers enhance both product quality and production performance.

Industry Challenges in Personal Care Injection Molding

Extremely High Aesthetic Requirements: High gloss, transparency, no weld lines, minimal color deviation.

Complex Product Structures: Multi-cavity molds, small parts, thin-walled designs.

Eco-friendly Pressure: Rising use of PCR plastics and reduction of material waste.

High Output Demand: Fast product cycles require efficient, repeatable manufacturing.

Traditional cold runner systems are no longer sufficient to meet the demands of high-end personal care brands. Stable and precise temperature control has become essential.

Key Benefits of Hot Runner Temperature Controllers

Precision Temperature Control

Independent temperature control for each nozzle/heating zone, with ±1°C accuracy, helps eliminate defects like burn marks, stringing, and short shots. This ensures smooth surfaces and consistent color.

Increased Production Efficiency

No cold runner, no gate trimming, shorter cycle times, and support for high-cavity mold injection—enabling faster, large-scale production.

Reduced Material Waste

Hot runner systems eliminate cold runners, improving raw material utilization—especially important for high-cost resins or recycled plastics.

Supports Complex Product Design

Perfect for dual-shot molding, clear parts, thin-walled components, and intricate aesthetics often required in personal care packaging.

Common Applications in Personal Care

| Product Type | Application | Molding Requirements | Temperature Control Benefit |

| Lipstick tubes, mascara bottles | Cosmetic packaging | High gloss, no weld lines | Precise control prevents defects |

| Electric toothbrush housing | Personal care electronics | Tight tolerance, consistent fit | Multi-zone control ensures accuracy |

| Razor handles | Body-contact items | Smooth surface, no flash | Stable heat reduces deformation |

| Shampoo/body wash bottles | Daily use packaging | High repeatability, fast cycle | Supports multi-cavity injection |

Boosting Sustainability & Brand Value

Hot runner systems with smart temperature controllers help brands achieve:

1.Zero-waste molding

2.Lower carbon emissions and energy use

3.Stable processing of PCR and eco-materials

4.Easier compliance with green certifications (e.g., ECOCERT)

More Than Just a Controller: Our Full Solution

At Topower, we offer complete hot runner system solutions including:

✅ Hot Runner Temperature Controllers (4, 6, 12, or custom zones).

✅ Time sequential controller, connection cable, connector, etc.

✅ Touchscreen interface and remote upgrade options.

✅ Rapid configuration, on-site support, and global service.