In modern injection molding, efficiency and precision are critical. Among the many mold design ...

Injection Molding Headaches: Temperature Issues You Can’t Ignore

In today’s highly competitive injection molding industry, the stability of product quality directly defines a company’s core competitiveness. Yet, many managers and engineers still struggle with persistent production challenges: uncontrollable color variations, dimensional fluctuations, soaring energy consumption, and unexpected downtime. The root cause of these issues often points to one critical factor—temperature control.

This article explores the four major temperature control challenges faced by injection molders and how innovative solutions can help overcome them.

Surface Defects & Dimensional Instability: How Inconsistent Temperature Damages Quality and Reputation

Color Variation: Differences between batches or cavities, caused by temperature fluctuations that affect pigment dispersion or degradation.

Gloss Inconsistency: Uneven cavity surface temperatures lead to inconsistent crystallinity, resulting in glossy and dull patches.

Flow Marks & Weld Lines: Insufficient melt temperature prevents proper fusion, often linked to nozzle, runner, or mold temperature issues.

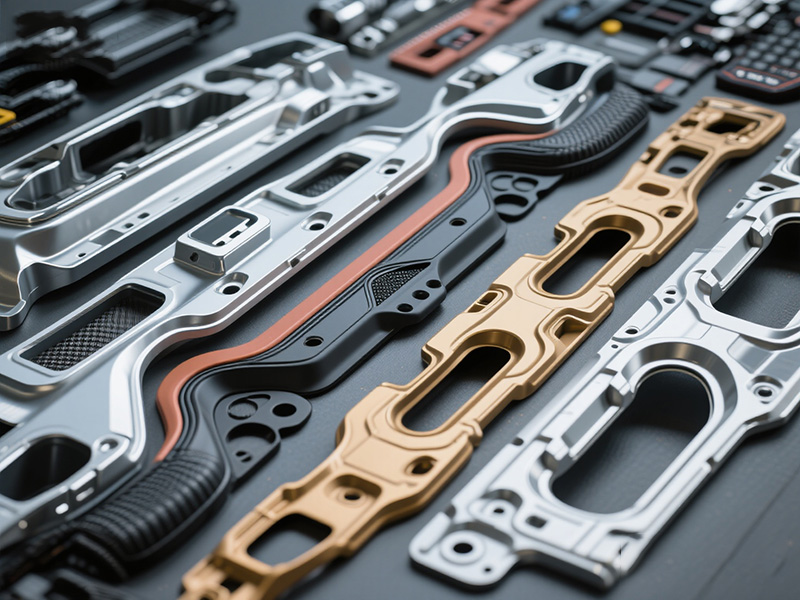

Dimensional Instability: Temperature instability directly affects shrinkage rates, causing tolerance failures—especially critical in electronics and automotive components.

Temperature imbalance also leads to:

High Internal Stress: Uneven cooling generates stress, causing warpage, cracking, or stress-induced failure.

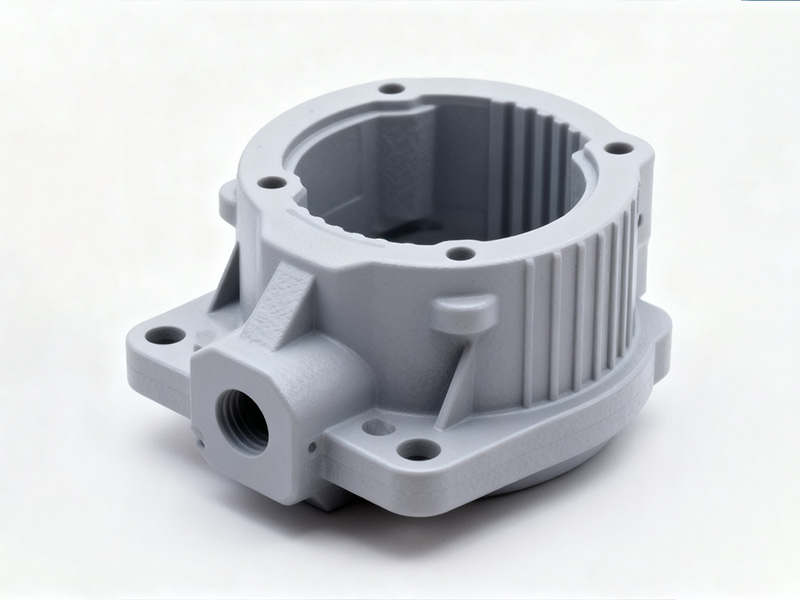

Material Degradation: Overheating or long residence times cause thermal degradation in sensitive materials like PVC, creating black spots, bubbles, or reduced mechanical strength.

Efficiency & Cost Pressure: The Hidden Price of Poor Temperature Control

Long Start-up Time: Slow system response and instability prolong setup after mold or material changes.

High Energy Consumption: Outdated ON/OFF or PID controllers run inefficiently, with heaters constantly at full power, wasting electricity.

Unexpected Downtime:

Heater or thermocouple failure triggers alarms and production halts.

Poor gate temperature control causes drooling or stringing, requiring manual cleaning and interrupting automation.

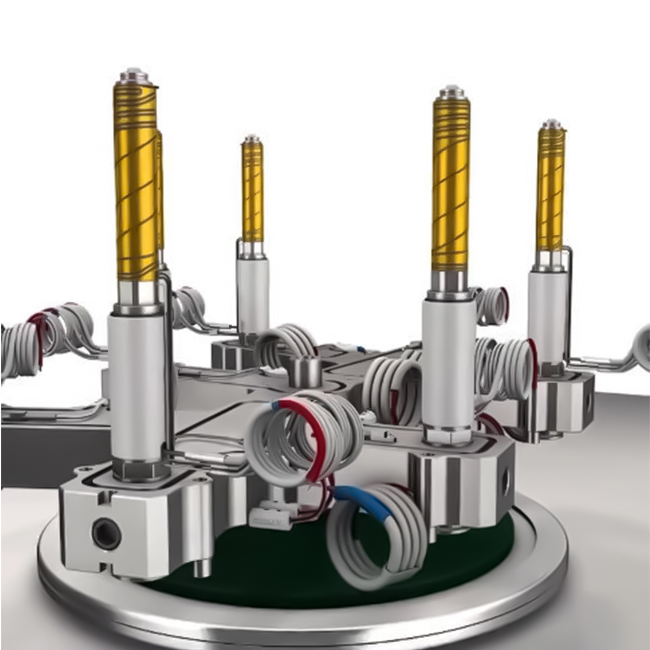

Technical Complexity: Controlling Multi-Cavity Molds and Special Processes

Large Multi-Cavity Molds: The more cavities, the harder to ensure uniform temperature—hot spots and cold spots reduce yield.

High-Temperature Materials (PEEK, PEI): Operating above 400°C for extended periods demands extreme durability and accuracy from heaters and sensors.

Multi-Material Injection: Different resins require different temperatures; balancing them within a single mold is highly complex.

Micro-Injection: Tiny cavities are extremely sensitive—small temperature variations cause short shots or flash.

Hot Runner Temperature Gradient: Ideally uniform, but unavoidable heat loss from manifold to gate tip requires precise compensation.

Maintenance & Intelligence: Why Traditional Methods Fall Behind

Lack of Predictive Maintenance: Most plants follow a “fix when it fails” model, resulting in costly downtime.

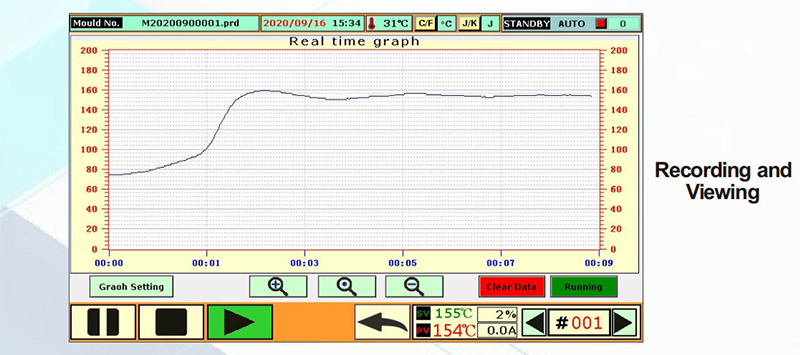

Underutilized Data: Advanced controllers generate valuable data (curves, power output, alarms), but few use it for process optimization or health monitoring.

Low Intelligence: Process settings rely heavily on experienced engineers; lack of smart automation leads to inconsistent product quality across shifts.

The Solution & Value Proposition

In today’s market, molders—especially SMEs—need to improve quality while controlling costs. Yet, international brand controllers are often overpriced, and trial-and-error testing of different systems is both time-consuming and costly.

This is where Topower Hot Runner Temperature Controllers deliver value. With a balanced price-performance ratio, proven stability, and CE & RoHS certification, we provide reliable and cost-effective solutions for both SMEs and large manufacturers.

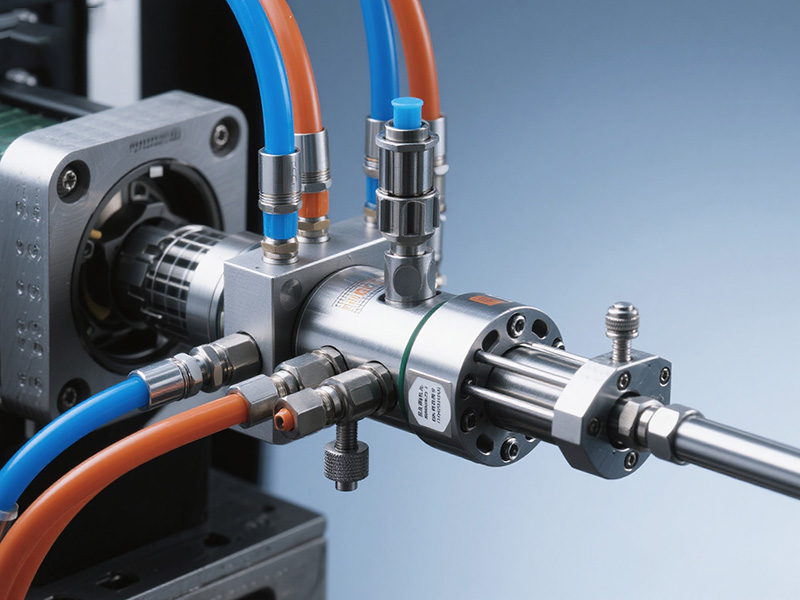

Our controllers feature:

Precise temperature control & fast response

Mold protection & tool-free maintenance

Full range of 12–120 zones

They effectively solve issues like color variation, dimensional instability, excessive energy consumption, and downtime—helping you achieve higher yields and efficiency without endless trial and error.

By choosing the right temperature control system, you’re choosing a more efficient and competitive future.

Contact us today to learn how Topower solutions can reduce costs and boost efficiency in your injection molding production.