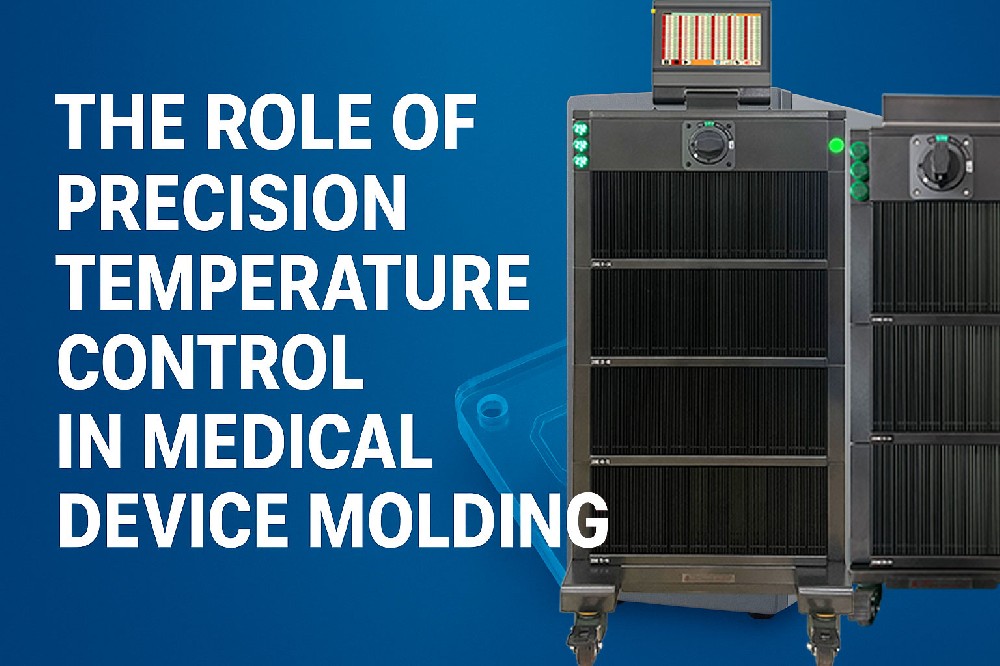

The Role of Precision Temperature Control in Medical Device Molding with Hot Runner Temperature Controllers

Injection molding is the foundation for producing high-quality medical device components such as syringes, catheters, and surgical tool handles. In this process, precise control over temperature...

Energy-Saving Strategies with Hot Runner Temperature Controllers in Mass Production

IntroductionIn today’s competitive manufacturing environment, energy efficiency is no longer optional—it’s a necessity. Rising electricity costs and stricter sustainability regulations are pushing ...

5 Ways Advanced Temperature Control Enhances Cycle Time and Productivity

IntroductionIn the world of injection molding, efficiency is everything. From reducing production costs to meeting tight deadlines, manufacturers are constantly searching for ways to enhance cyc...

Hot Runner vs Cold Runner: Which Is Best for Your Mold Design?

Choosing the right runner system is one of the most important decisions in injection molding. Two popular options dominate the industry: hot runner systems and cold runner systems. Both play a cr...

Injection Molding Headaches: Temperature Issues You Can’t Ignore

In today’s highly competitive injection molding industry, the stability of product quality directly defines a company’s core competitiveness. Yet, many manage...

How Hot Runner Systems Are Revolutionizing Electronic Component Molding

IntroductionThe electronics industry is advancing at a rapid pace, driven by the need for miniaturized, high-precision components used in smartphones, automotive electronics, and smart devices. H...

Hot Runner Temperature Controller Troubleshooting: Common Problems and Solutions

Hot runner systems are essential for precise temperature control in plastic injection molding. A well-functioning hot runner temperature controller ensures consistent product quality, reduces ma...

Material Selection for Hot Runner Nozzles and Manifolds in Automotive Applications

When it comes to automotive injection molding — including under-hood parts, structural brackets, interior trim, and high-precision connectors — the choice of materials for hot runner nozzles and man...