Product Introduction

Time sequential controller is divided into hydraulic valve and pneumatic valve, which correspond to two different hot runner molds;

TMC model is mainly used in the needle valve hot runner injection system,

through the detection of the clamping signal of the injection molding machine,

according to the customer's needs of the mold injection can be adjusted to delay the clamping injection and different time off the needle valve,

accurately open and close the pneumatic needle valve nozzle valve pin, to make the injection product without the needle valve.

1. 1-8 independent channels, can be set according to actual needs

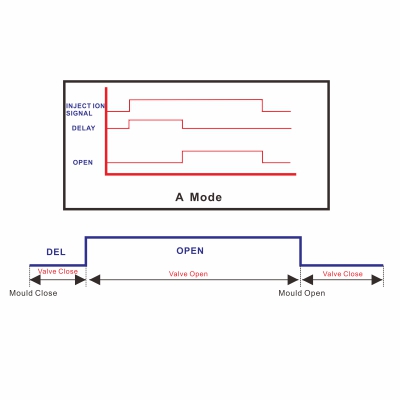

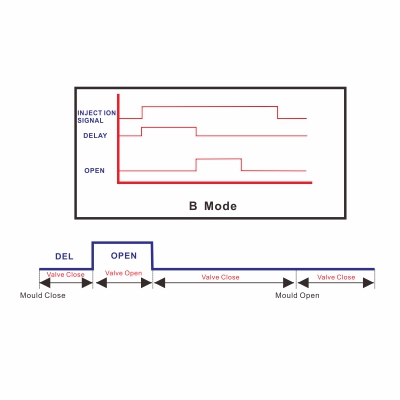

2. Two modes of operation (Mode A and Mode B), single/dual segment

3. Manual/automatic valve opening mode

4. Output signal 24/220V

Single-segment delay mode, when mould closing,

the needle valve will open after first segment delay time and will close needle after mould opens.

Two-segment delay mode, when mould closing,

the needle valve will open after first segment delay time and will close automatically after second segment delay time.