Choosing the right material is one of the most critical steps in automotive plastic injection ...

What is the Difference Between the Mold of the Blow Molding Machine and the Mold of the Injection Molding Machine?

In the world of plastic manufacturing, blow molding and injection molding are two essential processes used to produce a vast range of plastic products. While both involve molding plastic through the use of heat and pressure, they differ significantly in terms of tooling, process, application, and the equipment involved — especially the molds. In this article, we will dive deep into the differences between the mold of the blow molding machine and the mold for injection molding machine, along with how hot runner controllers and temperature controllers play a critical role in the injection molding process.

What Is the Mold of the Blow Molding Machine?

The mold used in blow molding is typically a hollow metal cavity into which melted plastic is formed. Unlike injection molds that are generally more complex, blow molds are relatively simple and are usually split into two halves that close around a tube of molten plastic, known as a parison.

These molds are usually made of aluminum or steel and are designed to form hollow objects such as bottles, containers, and tanks. The internal cavity of the blow mold determines the shape and size of the final product.

Blow molds must be designed to withstand repeated opening and closing and the forces of air pressure used to shape the plastic against the inner walls of the mold.

The Blow Molding Process

The blow molding process starts by melting plastic and forming it into a parison or preform. Once the parison is enclosed inside the mold, compressed air is blown into it, inflating the parison against the mold walls. As the plastic cools and solidifies, it takes the shape of the mold cavity. After sufficient cooling, the mold opens and the final product is ejected.

There are three primary types of blow molding:

Extrusion Blow Molding (EBM)

Injection Blow Molding (IBM)

Stretch Blow Molding (SBM)

Blow molding is ideal for high-volume production of hollow plastic parts and containers.

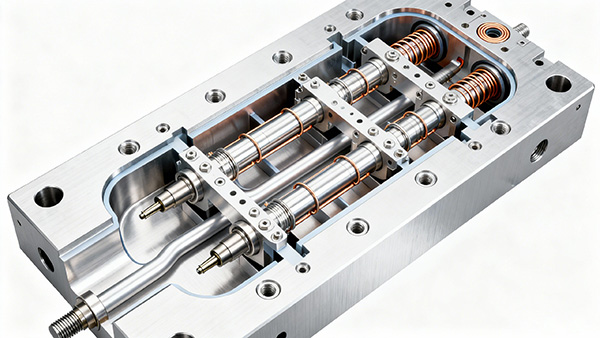

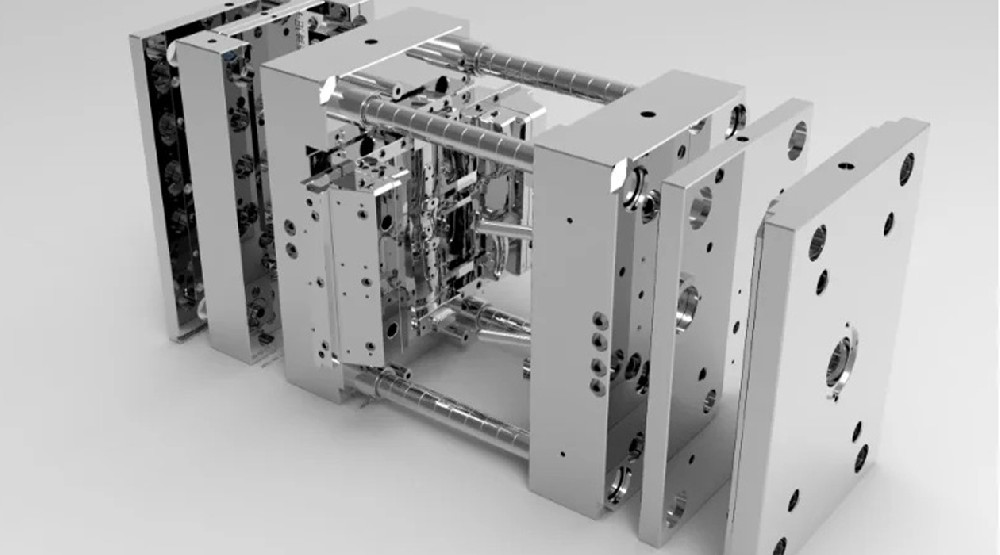

What Is the Mold of the Injection Molding Machine?

The mold for injection molding machine is more intricate and precise than blow molds. It usually consists of a core and cavity with complex channels for heating and cooling. These molds are designed to produce solid, high-precision parts, often with tight tolerances and intricate geometries.

Injection molds also include components such as:

Ejector pins to remove the molded part

Cooling channels for quick solidification

Sprue, runners, and gates for material flow

Hot runner systems, which use a hot runner temperature controller to keep the material in a molten state within the mold.

Injection molds are made from hardened steel or beryllium-copper alloy, depending on the production volume and desired finish.

What Is the Molding Process of an Injection Molding Machine?

The molding cycle includes the following steps:

Clamping: The mold halves are closed securely.

Injection: Molten plastic is injected into the mold cavity through the runner injection moulding system.

Cooling: The part is allowed to cool and solidify inside the mold.

Ejection: Ejector pins push the finished part out of the mold.

Modern injection molding machines in injection molding China factories often feature automation, robotic handling, and advanced thermal control systems.

The Advantages and Disadvantages of Blow Molding and Injection Molding

Aspect | Blow Molding | Injection Molding |

Advantages | - ldeal for hollow parts - Lower mold cost - Faster cycle times | - High precision and surface finish -Suitable for complex geometries - Wide material compatibility |

Disadvantages | - Limited to hollow parts - Less accurate wall thickness control | - High mold cost - Longer development time |

Choosing between the two depends on the product type. Hollow objects like bottles require blow molding, while detailed parts like phone cases, auto components, and appliances are best produced through injection molding.

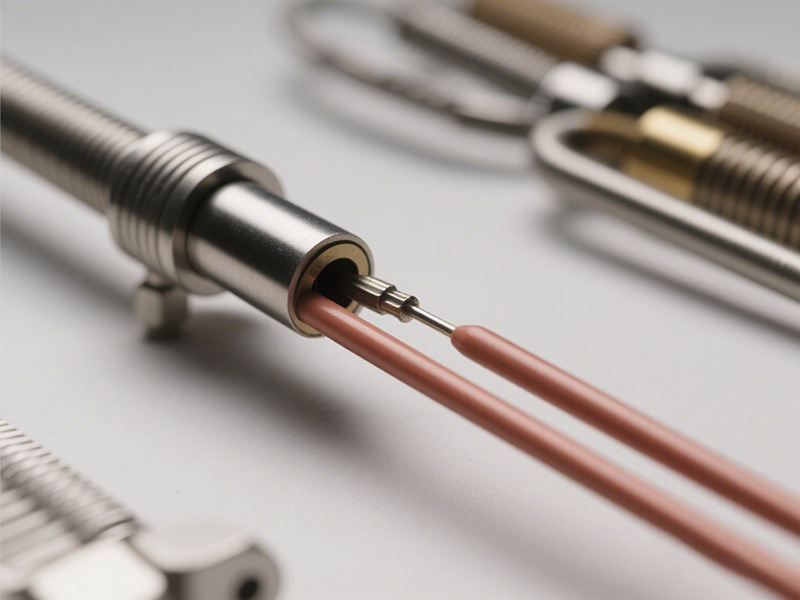

How Topower Hot Runner Temperature Controllers Work with Injection Molding Machines

In modern injection molding, especially in high-volume production, hot runner systems are widely used to improve efficiency and reduce waste. A hot runner is a heated component that keeps the plastic in molten form inside the mold until it’s injected into the cavities.

This is where Topower hot runner temperature controllers come in.

A hot runner temperature controller regulates the temperature of the hot runner system precisely, ensuring that the plastic remains at optimal flow conditions. Consistent temperature control prevents issues such as:

Material degradation

Flow imbalance

Short shots or overfilling

Defects in surface finish

How do temperature controllers work in this context? They typically monitor sensors embedded in the hot runner system and adjust the heating elements accordingly. For instance, if a specific zone becomes too hot, the controller will reduce power to that zone. Topower's hot runner controllers offer multi-zone temperature regulation, real-time monitoring, and alarm systems for safer and smarter molding.

Using a quality hot runner controller significantly enhances the consistency of the molding process, especially when dealing with complex molds and multi-cavity production.

Conclusion

Understanding the differences between blow molding and injection molding — especially their respective molds — is essential for selecting the right process for your plastic product. Blow molding offers an economical solution for hollow items, while injection molding provides high precision for complex parts.

Moreover, advanced systems like Topower hot runner temperature controllers are transforming injection molding by providing enhanced thermal management, reducing cycle time, and improving product quality. In today’s competitive manufacturing environment, especially in places like injection molding China, these technologies are key to delivering reliable, high-volume, cost-efficient production.

Whether you're working with a runner injection moulding system or deciding between molding methods, the right combination of mold design, process control, and thermal management tools like hot runner controllers will ensure superior results in your production line.