The Role of Zones in a Hot Runner Control SystemIn injection molding, the hot runner control s...

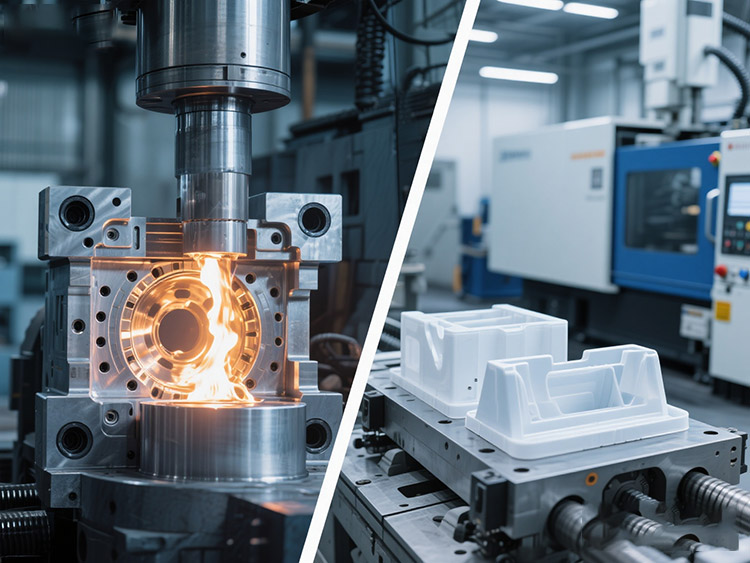

Temperature Control in Automotive Plastic Molding

In automotive injection molding, precise temperature control is critical to ensure dimensional accuracy, surface quality, energy efficiency, and safety. Parts like dashboards, bumpers, and engine covers require stable molding conditions for consistency and durability.

Quality and Process Control

Temperature affects how plastic flows and solidifies. Proper control helps:

Maintain Shape: Stable mold temperatures reduce warping and shrinkage. Uneven cooling causes internal stress, shading, or warpage. Monitoring temperature differences (ΔT ≤ 3–5 °C) and using turbulent coolant flow ensure uniform cooling.

Improve Surface Finish: Consistent cooling avoids defects like weld lines and sink marks. High-gloss finishes depend on uniform mold temperatures. Digital mold-temperature controllers can cut cosmetic rejects.

Avoid Defects: Too-low temperatures cause short shots and cracks; too-high prolongs cooling but can improve strength. Real-time temperature adjustments keep the melt within optimal range for each plastic type.

Energy Efficiency

Modern temperature-control systems enhance energy use by optimizing heating/cooling:

Variable Pump Control: Systems with ΔT control adjust pump speeds, reducing energy up to 90%. One facility cut cooling electricity from 14,500 kWh to 1,160 kWh annually.

PID Algorithms & Inverters: These manage heaters and pumps efficiently, minimizing overshoot and waste.

Smart Cooling Systems: Advanced chillers match cooling to demand, cutting compressor energy by ~30%. Engel’s iQ flow system reduces cooling-water use by ~50%.

Lower Start-Up Waste: Accurate heating speeds warm-up, reduces thermal lag, and shortens cycle times—sometimes by 30%.

Heating, cooling, and pumping systems can account for up to 80% of a plant’s energy use. Insulated lines and optimized circuits further reduce demand.

Safety and Equipment Protection

Good temperature control protects both machines and personnel:

Overheat Detection: Thermocouples on barrels, nozzles, and molds trigger alarms or shut-offs if limits are exceeded.

Safety PLCs: Integrated systems prevent mold operation under unsafe temperatures and control emergency stops.

Preventing Hazards: Stable temperatures prevent oil bursts and thermal cracking. Cooling failures are caught early, avoiding fire or equipment damage.

Key Technologies

Modern systems use various tools to manage temperature precisely:

Mold Temperature Controllers (MTCs): Circulate water or oil to heat/cool molds. Water suits up to ~100 °C, oil for higher. Multi-zone units manage complex molds.

Sensors: Thermocouples (J/K types) and IR probes measure real-time mold, melt, or coolant temperatures. Data feeds into control systems.

Chillers/Heaters: Maintain coolant temperature and pressure. Features like variable-speed drives reduce energy use.

Automated Control (PLCs & IoT): PLCs run feedback loops; IoT integration allows remote monitoring and predictive maintenance. Some systems halt production if unsafe temperature drift is detected.

System choice depends on material and part needs. High-precision molds may use multi-zone oil control; simple parts can use single-circuit water MTCs.

Conclusion

In automotive molding, temperature control is essential. It improves part quality, shortens cycles, saves energy, and ensures safety. Technologies range from basic thermocouples to intelligent, connected systems. Investing in robust control delivers better results and long-term efficiency—crucial in competitive manufacturing.