The Role of Zones in a Hot Runner Control SystemIn injection molding, the hot runner control s...

5 Ways Advanced Temperature Control Enhances Cycle Time and Productivity

Introduction

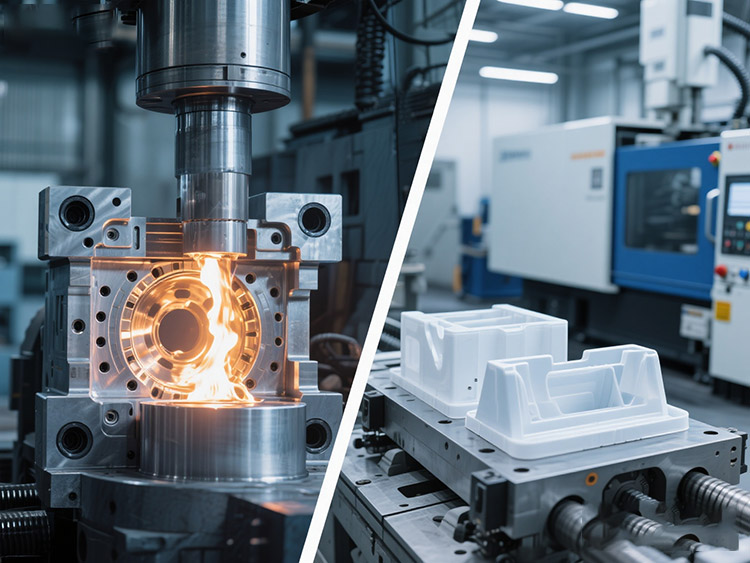

In the world of injection molding, efficiency is everything. From reducing production costs to meeting tight deadlines, manufacturers are constantly searching for ways to enhance cycle time and improve overall productivity. One key factor that can make a significant difference is temperature control. Advanced hot runner temperature controllers are no longer just optional; they are critical for achieving precision, consistency, and energy savings in modern manufacturing.

This article explores why temperature control matters and the five major ways advanced systems can transform your production line.

Why Temperature Control is Critical in Injection Molding

Temperature stability is the backbone of injection molding quality. The molten plastic must flow evenly and solidify consistently to achieve high-quality parts. If temperature fluctuates, you risk warping, surface defects, dimensional inaccuracies, and even part rejection.

Common issues caused by poor temperature control include:

Uneven melt flow leading to incomplete filling

Surface finish defects like sink marks or burn spots

Inconsistent part dimensions affecting assembly compatibility

Simply put, without precise control, your process will struggle to maintain consistency—resulting in wasted time, materials, and money.

5 Ways Advanced Temperature Control Boosts Cycle Time and Productivity

Ensures Optimal Melt Flow for Faster Cycle Times

By maintaining precise heating across all hot runner zones, advanced controllers ensure smooth melt flow, reducing fill time and preventing cold spots. This directly translates to shorter cycle times without compromising part quality.

Reduces Defects and Rework, Improving Overall Output

Defective parts lead to downtime and increased costs. Stable temperature control minimizes defects such as flashing, warpage, and short shots, significantly reducing the need for rework.

Maintains Consistent Temperature Across Multi-Cavity Molds

For molds with multiple cavities, multi-zone controllers ensure that every cavity receives the correct amount of heat, resulting in uniform part quality and preventing imbalance issues.

Integrates Smart Features for Real-Time Adjustments

Modern controllers are equipped with IoT capabilities and real-time monitoring, allowing operators to adjust parameters on the fly, detect problems early, and prevent costly downtime.

Improves Energy Efficiency and Lowers Production Costs

Advanced systems utilize optimized heating algorithms, such as PID control, which reduces power consumption and enhances overall energy efficiency—a crucial factor for sustainable manufacturing.

Key Features of Advanced Hot Runner Temperature Controllers

Multi-Zone Control: Ideal for large or complex molds

PID Control Accuracy: Keeps temperature within tight tolerances

Smart Connectivity: IoT integration for remote monitoring and predictive maintenance

Common Mistakes in Temperature Control and How to Avoid Them

Incorrect Sensor Placement: Leads to inaccurate readings

Neglecting Calibration: Over time, uncalibrated systems drift away from optimal performance

Ignoring Heater Health: Regular checks are essential for consistent results

How Improved Cycle Time Impacts Profitability

Reducing cycle time doesn’t just improve throughput—it boosts your profit margins. Faster cycles mean:

More parts per hour, increasing overall production

Lower machine downtime, reducing labor and maintenance costs

Faster order fulfillment improves customer satisfaction

Future Trends in Hot Runner Temperature Control

The future of temperature control technology is moving toward:

AI-driven predictive control for automated adjustments

Energy-saving algorithms for sustainability

Cloud connectivity for remote diagnostics and performance analytics

How Topwer Hot Runner Controllers Can Help Your Business

At Topwer, we specialize in high-performance hot runner temperature controllers designed to deliver:

Precision and stability for multi-cavity molds

Smart features for real-time adjustments

Energy-efficient solutions for sustainable manufacturing

Explore our full range of products on CNTOPower.com and discover how we can help you reduce cycle time and maximize productivity.

Contact us today for a free consultation or a customized solution.

FAQs About Temperature Control in Injection Molding

What is the ideal temperature for hot runner systems?

It depends on the plastic material, but generally, maintaining ±1°C stability is crucial for consistent results.

How does cycle time affect production cost?

Shorter cycle times allow for more parts in less time, significantly lowering cost per unit and increasing profitability.

Can temperature control reduce scrap rate?

Yes, precise control minimizes defects like flashing, warpage, and incomplete fills, reducing scrap and improving yield.

What are the benefits of a multi-zone temperature controller?

It ensures uniform heating in large molds, improving consistency across all cavities.

How do smart temperature controllers support Industry 4.0?

They integrate with IoT for real-time monitoring, predictive maintenance, and data-driven optimization.