IntroductionIn today’s competitive manufacturing environment, energy efficiency is no longer option...

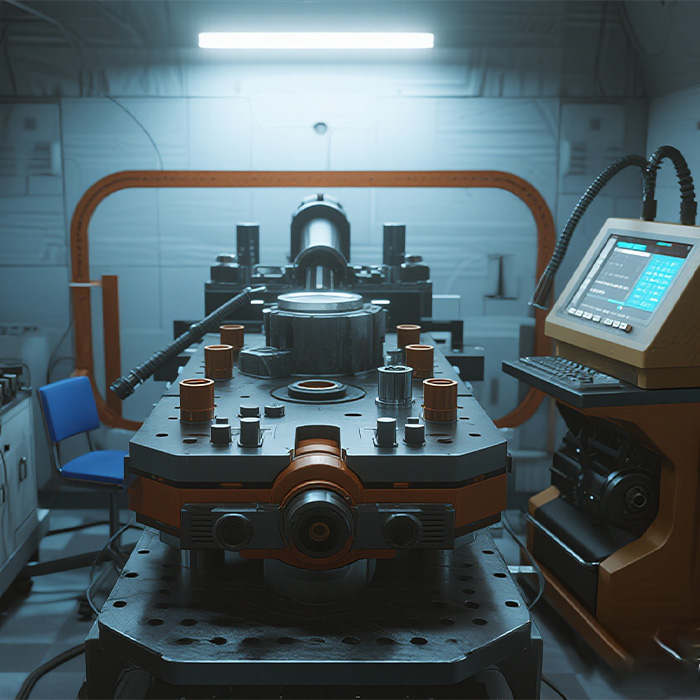

Energy-Saving Strategies with Hot Runner Temperature Controllers in Mass Production

Introduction

In today’s competitive manufacturing environment, energy efficiency is no longer optional—it’s a necessity. Rising electricity costs and stricter sustainability regulations are pushing manufacturers to rethink their production strategies. Among the many factors influencing energy consumption, hot runner systems play a significant role.

Advanced hot runner temperature controllers are designed not only to maintain temperature stability but also to reduce energy usage without compromising part quality. In this article, we’ll explore why energy-saving strategies matter, how temperature control impacts power consumption, and five proven ways to make your injection molding process more energy-efficient.

Why Energy Efficiency Matters in Injection Molding

Energy costs are one of the largest operating expenses in injection molding. The heating elements in hot runner systems consume a substantial amount of power to maintain consistent temperatures during production cycles.

Additionally, environmental compliance and corporate sustainability goals are becoming mandatory in many regions. Manufacturers who ignore energy optimization risk losing competitiveness, facing higher costs, and potential penalties. Implementing energy-saving strategies not only lowers expenses but also strengthens your brand’s position as an eco-conscious supplier.

How Hot Runner Temperature Controllers Influence Energy Usage

Hot runner systems rely on precise heating to maintain the melt temperature of plastic inside the mold. Any inefficiency in temperature control can lead to:

Excessive heating cycles due to poor regulation

Energy waste from overheating during idle times

Temperature fluctuations that increase defect rates and scrap

Advanced temperature controllers use smart algorithms like PID (Proportional-Integral-Derivative) control, ensuring optimal energy delivery without overshooting or power spikes. By stabilizing the temperature and avoiding unnecessary reheating, these systems can cut energy consumption significantly.

5 Proven Energy-Saving Strategies Using Temperature Controllers

Implement PID Control for Accurate Heat Management

Traditional on/off controls cause frequent heating and cooling cycles, which waste energy. PID control ensures smooth, precise temperature adjustments, reducing power fluctuations and maintaining energy efficiency.

Optimize Preheating and Standby Modes to Reduce Idle Power

Many systems continue consuming power even when idle. Advanced controllers allow for energy-saving standby modes and optimized preheating schedules, minimizing wasted electricity during downtime.

Leverage Multi-Zone Control for Precision and Efficiency

Large molds with multiple cavities often require different temperature settings. Multi-zone controllers distribute heat accurately across zones, avoiding unnecessary heating in areas that don’t need it—saving energy while improving consistency.

Integrate Smart Monitoring to Track and Optimize Energy Usage

Modern controllers come with real-time monitoring and IoT connectivity, allowing operators to analyze energy data and make adjustments instantly. This feature helps identify energy-intensive processes and implement corrective measures.

Adopt Predictive Maintenance to Prevent Overheating and Power Waste

Heaters degrade over time, leading to inefficient energy usage. Predictive maintenance powered by smart controllers helps identify failing components early, preventing energy loss and costly breakdowns.

Case Study: How Advanced Controllers Reduced Power Consumption by 20%

One of our clients, a large-scale automotive parts manufacturer, implemented CNTOP’s advanced hot runner temperature controllers across 24 injection molding machines. By leveraging PID control, multi-zone optimization, and standby modes, they achieved:

20% reduction in energy consumption

Improved part quality and reduced scrap rate

ROI within six months

This case highlights how energy-saving strategies directly impact profitability and sustainability.

The Connection Between Energy Savings and Production Profitability

Energy efficiency doesn’t just cut utility bills—it improves your bottom line. Here’s how:

Lower operating costs mean more competitive pricing for your customers.

Improved efficiency results in faster cycle times and higher output.

Compliance with green manufacturing standards strengthens your brand image.

Want to learn how temperature control also improves productivity?

Check out our article: 5 Ways Advanced Temperature Control Enhances Cycle Time and Productivity

Future Trends: Green Manufacturing and IoT Integration

The next generation of temperature control systems will focus on:

AI-driven energy optimization, predicting power needs in real-time

Cloud-based analytics, enabling remote monitoring and decision-making

Integration with renewable energy sources, supporting carbon-neutral production

These trends are shaping the future of Industry 4.0 and sustainable manufacturing.

How Topwer Helps You Achieve Energy Efficiency

At CNTOP, we provide advanced hot runner temperature controllers engineered for energy optimization, precision control, and intelligent monitoring. Our solutions help you:

Reduce power consumption by up to 20%

Achieve consistent part quality

Meet sustainability goals without compromising productivity

Explore our full range of temperature control systems. Contact us today for a custom energy-saving solution tailored to your production line.

FAQs About Energy Efficiency in Hot Runner Systems

How much energy can advanced temperature controllers save?

Typically, they can reduce energy consumption by 10–20%, depending on your current setup and process conditions.

Do smart temperature controllers require additional investment?

Yes, but the ROI is fast, often within 6–12 months, due to energy savings and improved productivity.

Can older systems be upgraded for better energy efficiency?

Absolutely. Many retrofit solutions are available to integrate advanced controllers with existing hot runner systems.

Does energy-saving compromise part quality?

No. In fact, precise temperature control enhances part consistency and reduces defects, improving overall quality.

How do IoT and Industry 4.0 improve energy efficiency?

IoT-enabled controllers allow real-time energy monitoring, predictive adjustments, and cloud-based analytics for smarter energy management.