Choosing the right material is one of the most critical steps in automotive plastic injection ...

How to Choose the Best Hot Runner Temperature Controller for Mold Manufacturing

Introduction

In the world of injection molding, precision is everything. The slightest fluctuation in temperature can lead to defective parts, higher scrap rates, and costly downtime. That’s why investing in a high-quality hitech control is crucial for mold manufacturers who want to achieve consistent part quality, efficient production cycles, and long-term cost savings.

However, with numerous options available, how do you select the ideal hot runner controller for your molding requirements? This guide will walk you through everything you need to know—from the basics of hot runner controllers to the features that matter most, and how to make a smart purchase decision for your business.

What is Hot Runner Temperature Controller?

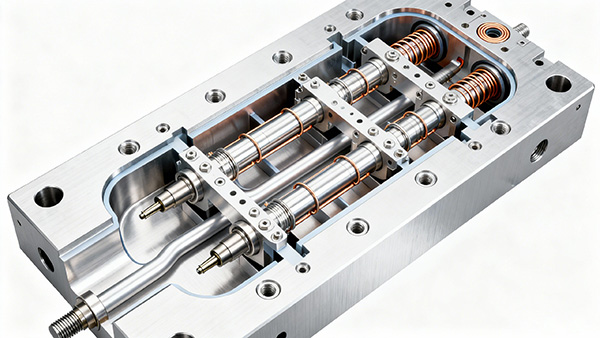

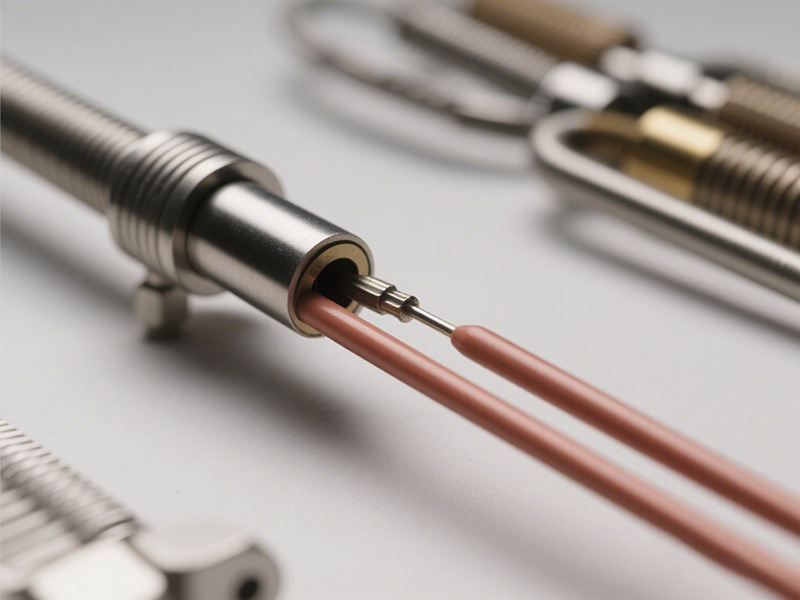

hot runner temperature controller is a specialized device used in injection molding systems to regulate the temperature of the hot runner system, which includes the manifold and nozzles that deliver molten plastic into the mold cavities.

Basic Function and Working Principle

The controller ensures that the melted polymer stays at the right temperature during flow, preventing premature cooling or overheating. It works by:

Monitoring temperature via thermocouples in each zone.

Adjusting heat output through control modules to maintain precise settings.

Providing alarms and safety shut-offs in the event of temperature deviations.

Without accurate temperature control, you risk part defects like short shots, flash, and color streaks, which can significantly impact quality and production efficiency.

Why Temperature Control is Critical in Injection Molding

When it comes to injection molding, temperature consistency is non-negotiable. Here’s why:

Impact on Mold Quality and Part Performance

Poor temperature regulation can lead to:

Dimensional inconsistencies in molded parts.

Surface defects like flow marks or burn spots.

Material degradation, especially for heat-sensitive resins.

Energy Efficiency and Cycle Time Optimization

A well-calibrated hot runner controller helps:

Reduce cycle times by maintaining optimal melt flow.

Minimize material waste and scrap rates.

Lower energy costs through efficient heating control.

Types of Hot Runner Controllers

Choosing the right controller starts with understanding your options:

Analog vs Digital Controllers

Analog controllers are basic, low-cost, but lack precision and advanced features.

Digital controllers provide better accuracy, touch-screen interfaces, diagnostics, and connectivity for Industry 4.0 integration.

Pro Tip: If you’re running complex molds or multi-cavity systems, go digital for better control and data insights.

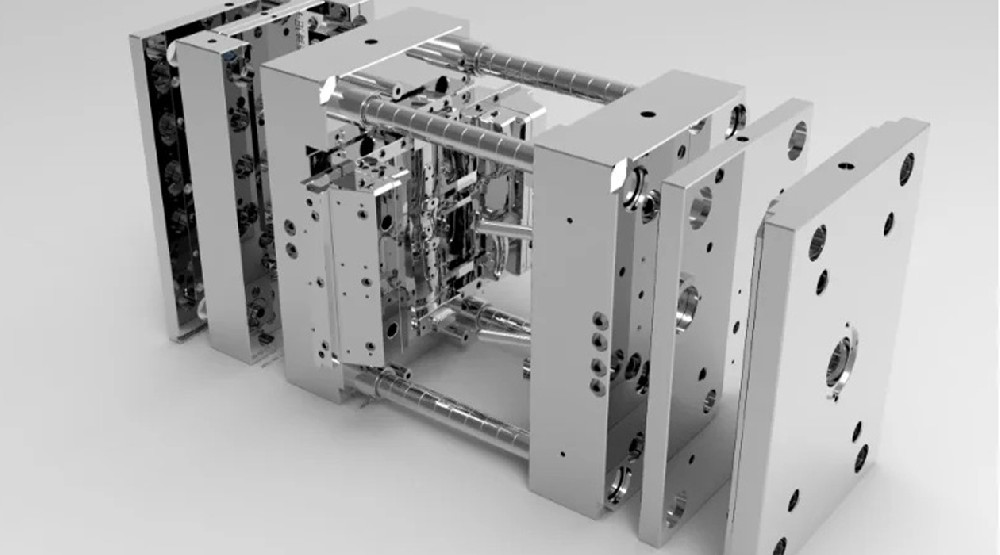

Multi-Zone vs Single-Zone Systems

Single-zone controllers handle simple applications with one heating point.

Multi-zone controllers manage multiple nozzles and manifolds independently, ideal for high-cavity molds.

Standalone vs Integrated Systems

Standalone controllers are portable and suitable for multiple molds.

Integrated controllers are built into the molding machine for space-saving and streamlined operation.

Key Features to Look for in HITECH Control

When evaluating controllers, don’t just look at the price—focus on value and functionality. Here are must-have features:

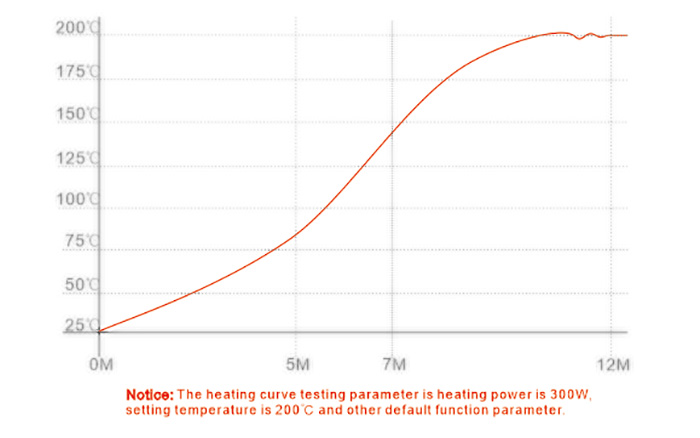

Accuracy and Stability

Look for ±0.1°C accuracy to ensure consistent quality.

Stable temperature prevents overheating and degradation of material.

User Interface and Ease of Operation

A touchscreen with clear menus makes setup easy.

Features like auto-tuning save time during mold changes.

Safety Features and Alarms

High/low temperature alarms.

Ground fault detection to prevent damage.

Data Logging and Connectivity

USB or Ethernet connectivity for process monitoring.

Industry 4.0 compatibility for smart factory integration.

Modular Design

Swappable modules for easy maintenance.

Allows expansion as your production grows.

How to Choose the Right Hot Runner Controller for Your Mold Design

When selecting a controller, consider:

Number of Zones

The more cavities and hot tips, the more zones you need. For example:

Small molds: 2–6 zones.

Large automotive molds: 24+ zones.

Material Type and Application

Different polymers have different processing windows:

Engineering plastics need tighter temperature control.

Commodity resins are more forgiving.

Budget vs Performance Trade-Off

Entry-level controllers may save money upfront, but lack long-term flexibility.

Advanced systems offer better accuracy, data tracking, and energy savings.

After-Sales Service and Support

Choose a supplier with:

24/7 technical support.

Spare parts availability.

Calibration services.

Common Issues with Poor Temperature Control (and How to Avoid Them)

Ignoring precision temperature control can lead to:

Short shots: caused by solidifying material before filling the cavity.

Flashing: due to excessive heat and material leakage.

Color streaks: from inconsistent melt temperature.

Solution: Invest in a reliable controller with auto-tuning and advanced diagnostics to detect and correct these problems early.

Benefits of Using Advanced Hot Runner Temperature Control Systems

Improved Part Quality: Fewer defects, better aesthetics.

Faster Startup Times: Auto-tuning reduces setup time.

Lower Scrap Rates: Precision reduces waste.

Energy Efficiency: Optimized heating reduces electricity bills.

Data-Driven Maintenance: Predictive alerts prevent downtime.

Top Recommended Hot Runner Controller Brands

When it comes to selecting a hot runner temperature controller, reliability and precision are key. Here are some trusted names in the industry:

Topower – A leading expert in hot runner temperature control systems, offering high-precision controllers, modular designs, and smart connectivity options. Perfect for mold manufacturers who demand consistent performance, user-friendly operation, and energy efficiency.

Gammaflux – Known for multi-zone precision and advanced connectivity.

Husky – Offers integrated control solutions for large, complex molds.

Yudo – A strong choice for cost-effective multi-zone systems.

Synventive – Provides modular, user-friendly controllers for diverse applications.

Why choose Topower?

Topower’s controllers are designed to meet the highest industry standards, ensuring:

Accurate temperature control (±0.1°C) for better product quality.

Intelligent features like auto-tuning, data logging, and Industry 4.0 compatibility.

Strong technical support and global service network.

Learn more about our products: Topower Hot Runner Controllers

Maintenance Tips for Long-Lasting Hot Runner Controllers

Regular calibration for accuracy.

Clean connections and thermocouples to prevent errors.

Update firmware for new features and bug fixes.

Store in a dry, clean environment when not in use.

Conclusion

Choosing the best hot runner temperature controller isn’t just about price—it’s about performance, precision, and long-term reliability. A good controller ensures:

Consistent mold quality.

Reduced scrap and downtime.

Better ROI over the lifecycle of your molds.

At Topower, we specialize in advanced hot runner temperature control solutions tailored to mold manufacturers. Our systems offer high precision, modular design, and smart connectivity, helping you stay competitive in today’s fast-paced plastics industry.

Ready to optimize your injection molding process?

Contact us today for expert advice and the best hot runner controller for your needs.