Choosing the right material is one of the most critical steps in automotive plastic injection ...

Understanding Hot Runner Heating Needs for Different Plastic Materials

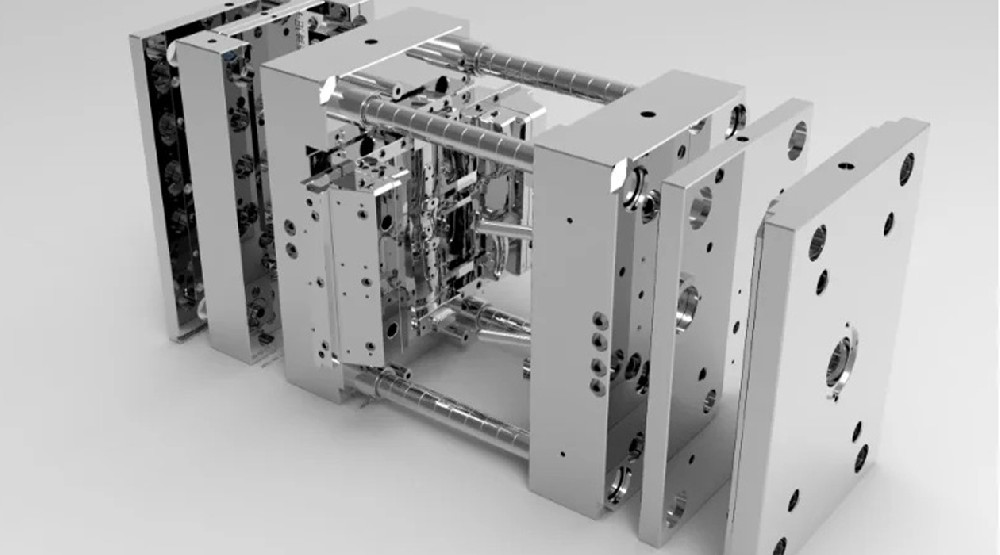

Hot runner systems play a crucial role in plastic injection molding, but their heating requirements vary significantly depending on the type of plastic being processed. Factors such as melting point, viscosity, and thermal stability directly influence temperature settings, heating uniformity, and system design. Understanding these differences is essential for ensuring smooth molding, preventing material degradation, and maintaining product quality.

Key Factors Affecting Heating Requirements

Analysis by Plastic Properties

Melting Point

High-melting-point plastics: Require higher processing temperatures, necessitating hot runners capable of reaching sufficiently high temperatures to fully melt the plastic and maintain its flowability.

Low-melting-point plastics: Require relatively lower processing temperatures, but overheating must be prevented to avoid degradation.

Viscosity

High-viscosity plastics: Exhibit poor flowability and require higher temperatures to reduce viscosity, ensuring complete mold filling. This demands higher flow rates and heating uniformity from the hot runner system.

Low-viscosity plastics: Flow at lower temperatures but require precise temperature control to prevent overheating and enhance product quality.

Thermal Stability

Plastics with poor thermal stability: Susceptible to temperature, prone to degradation or decomposition at elevated temperatures, releasing corrosive gases.

Requirements for these plastics:

① Precise temperature control: Avoid temperature fluctuations and overheating.

② Uniform heating: Prevent localized overheating zones to reduce degradation risk.

③ Appropriate heating rate: Rapid heating to minimize dwell time at elevated temperatures.

Plastics with good thermal stability (e.g., ABS): Can be processed stably at higher temperatures with relatively relaxed temperature requirements.

Analysis by Plastic Type

General-purpose plastics (PE, PP, PS, etc.)

Characteristics: Low melting points (120°C–250°C), good flowability, moderate thermal stability.

Heating requirements:

① Avoid excessively high hot runner temperatures to prevent melt degradation or yellowing from prolonged exposure.

② Recommend lower temperature settings and shorter holding times.

③ For oxidatively sensitive materials like PE and PP, prevent localized overheating in heating zones; multi-point temperature control is recommended.

Engineering Plastics (ABS, PC, PA, etc.)

Characteristics: Medium melting point (220°C–320°C), moderate flowability; some materials (e.g., PC) are highly temperature-sensitive.

Heating Requirements:

① Higher temperature control precision is essential to maintain stability and prevent surface defects (e.g., silver streaks, gas marks) caused by temperature fluctuations.

② ABS: Temperature-sensitive; hot runners must not exceed set upper limits to prevent decomposition, causing bubbles or color variations.

③ PC: Strict temperature control is essential for high-transparency products to prevent yellowing.

④ PA (Nylon): Highly hygroscopic; high moisture content during heating can cause surface porosity due to moisture evaporation, necessitating integration with a drying system.

High-Temperature Engineering Plastics (PPS, PEEK, LCP, etc.)

Characteristics: High melting points (300°C–400°C), excellent heat resistance and thermal stability, but a narrow processing window.

Heating Requirements:

① Hot runners must withstand temperatures exceeding 350°C for extended operation.

② Temperature controllers must ensure high precision (±1°C to ±2°C), otherwise uneven flow or decomposition may occur.

③ Heating zones require segmented control to ensure uniform temperature throughout the runner and prevent cold material blockage.

④ Insulation design is recommended to minimize heat loss and ensure heating efficiency.

High-Transparency Plastics (PMMA, PET, PC, etc.)

Characteristics: Extremely sensitive to temperature and impurities. Slight overheating or prolonged dwell times can cause yellowing, blackening, or gas marks in the product.

Heating Requirements:

① Hot runners must maintain stable temperatures without fluctuations.

② Temperature differences between heating zones should be kept within ±2℃.

③ Use polished runners and precision temperature controllers to prevent melt degradation.

④ PET: Commonly used for transparent preforms, requiring special attention to drying and crystallization control. Hot runner heating must operate within a narrow process window.

Practical Application Variations

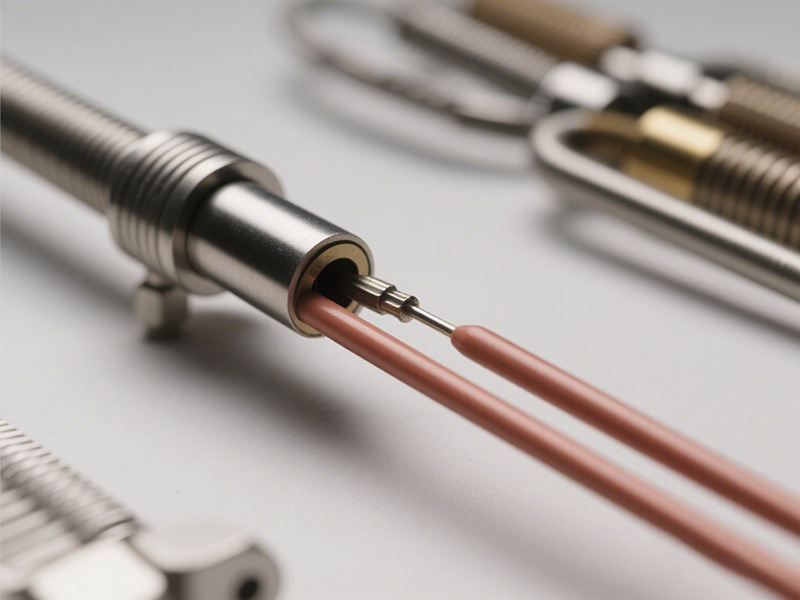

Heating Elements and Temperature Control Systems:

High-melting-point and high-viscosity plastics may require higher-power heating elements and more advanced temperature control systems to ensure sufficient heating capacity and precise temperature feedback.

Thermal Insulation Capability:

For plastics prone to degradation, hot runners require excellent thermal insulation to minimize temperature fluctuations while preventing overheating.

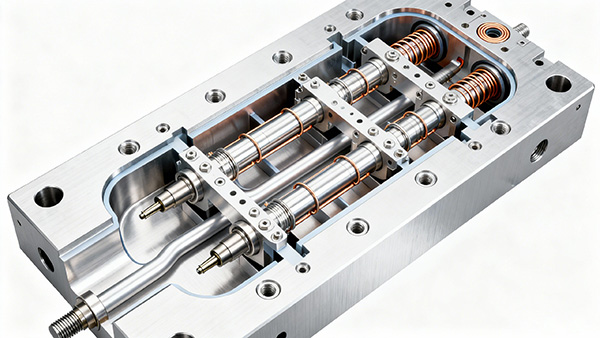

Runner Design:

Internal hot runner design elements (e.g., runner diameter, surface finish) must be optimized based on plastic viscosity to achieve smoother flow and more uniform heating.

Heating Speed:

For plastics requiring rapid molding or sensitive to dwell time, the hot runner system must enable fast ramp-up and uniform heating.

Conclusion

The heating requirements of hot runner systems depend heavily on the specific plastic material being processed. By carefully adjusting heating capacity, temperature control precision, and runner design to match material properties, manufacturers can enhance product quality, reduce defects, and improve production efficiency.