In modern injection molding, efficiency and precision are critical. Among the many mold design ...

Zone Control Matters: How to Choose the Right Number of Channels for Your Application

The Role of Zones in a Hot Runner Control System

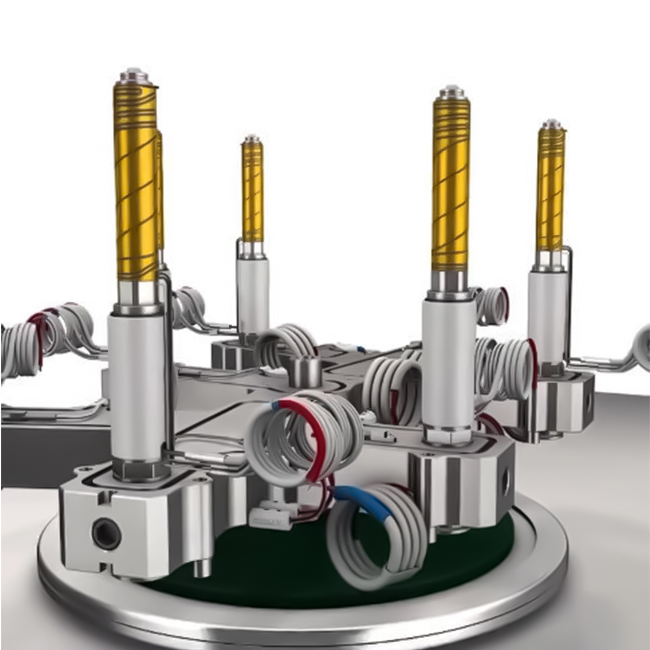

In injection molding, the hot runner control system plays a critical role in maintaining the temperature balance of molten plastic as it flows from the injection machine nozzle to each mold cavity. hot runner temperature controller divides the system into multiple heating zones, each managing specific heating elements such as manifolds and nozzles. By adjusting power independently, each zone ensures precise and stable temperature control.

Proper multi-zone control prevents the melt from overheating or cooling too quickly, which can otherwise lead to defects such as incomplete filling, burn marks, or dimensional inconsistency. This is particularly important for multi-cavity molds and asymmetric runner layouts, where temperature variations between flow channels can significantly affect part quality.

Factors to Consider When Selecting the Number of Zones

Choosing the right number of zones for your hot runner temperature controller depends on several mold and production requirements:

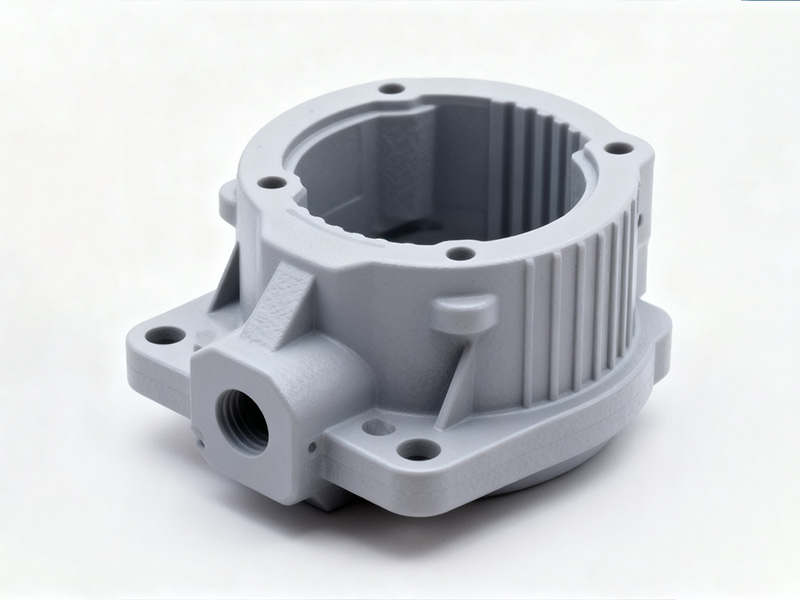

Number and distribution of cavities

The more cavities a mold has, the more zones are typically required. For instance, 32-cavity mold may need at least 4 heating zones, while a 64-cavity mold could require 8 or more. Independent zones ensure uniform heating for each manifold and nozzle.

Runner design and symmetry

Symmetrical runner designs can share zones, while asymmetric or long-flow paths often need additional independent zones to compensate for uneven heat distribution.

Product quality requirements

High-precision applications such as medical or optical components demand extremely stable temperature accuracy. More zones allow for fine adjustments and consistent part quality.

Material sensitivity

Engineering plastics and high-performance resins are highly sensitive to temperature fluctuations. More zones ensure precise control, while commodity plastics may tolerate fewer zones.

Practical guideline:

Small molds: typically 2–6 zones

Automotive or multi-cavity molds: 12–24 zones or more

Precision components: often require one zone per cavity for maximum accuracy.

Performance Differences Between Fewer and More Zones

Low-zone controllers (2–6 zones)

Compact, cost-effective, and easy to maintain, these are suitable for simple or low-cavity molds. However, sharing heating elements across fewer zones can cause temperature imbalances, leading to inconsistent part quality.

High-zone controllers (12+ zones)

Allow individual control of every nozzle and manifold, providing superior injection mold temperature control. While more complex and costly, they deliver higher accuracy, better compensation for local variations, and even reduce energy waste by shutting off unused zones.

Advantages of Intelligent Hot Runner Temperature Controllers

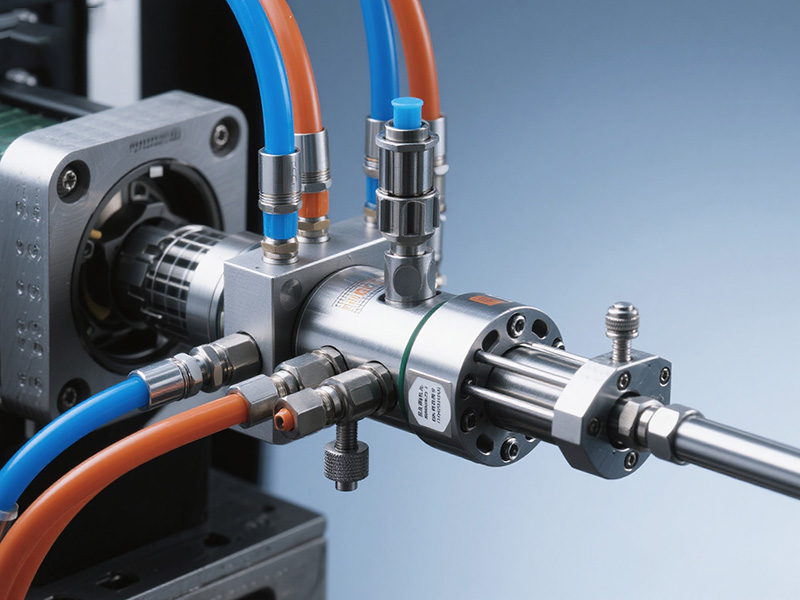

Modern intelligent systems, such as CNTOPower hot runner control boxes, combine advanced electronics with user-friendly interfaces to deliver outstanding performance:

High precision

With advanced PID self-tuning algorithms, CNTOPower controllers achieve control accuracy within ±0.1℃. This ensures long-term stability and consistent product quality, even in demanding applications.

Reliable and stable

Built with high-quality electronic components, the controllers provide stable operation, fast response, and real-time alarms to minimize downtime and reject rates.

Energy efficiency

Multi-zone smart heating strategies optimize power use by activating only the necessary channels. This reduces energy consumption while maintaining excellent temperature control accuracy.

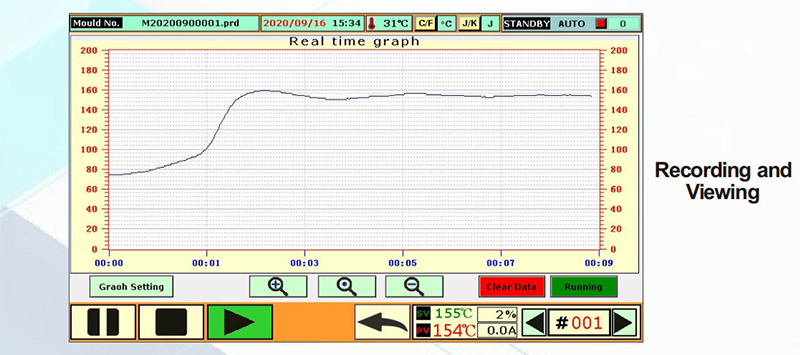

User-friendly operation

Touchscreen interfaces allow quick parameter setup, multi-recipe storage, and real-time temperature curves. Engineers and operators benefit from intuitive controls, faster troubleshooting, and reduced training time.

Application Scenarios and Selection Recommendations

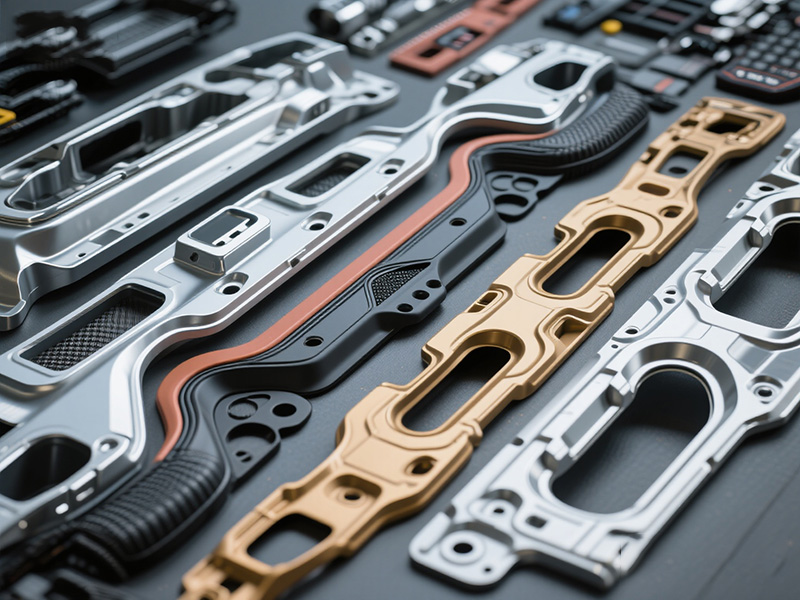

Consumer goods and household products

For low-precision, single-cavity, or small molds, a 2–6 zone controller is sufficient. It offers affordable performance and ease of maintenance.

Automotive and large molds

Complex parts and multi-cavity designs require 12 or more zones. More precise control ensures consistent filling, dimensional stability, and faster cycle times.

Medical, electronics, and precision parts

When tolerances are extremely tight, one zone per cavity is recommended. Combined with advanced sensors, this approach ensures precise temperature uniformity and maximizes part yield.

Conclusion

The number of zones in a hot runner temperature controller directly impacts temperature uniformity, part quality, and overall production efficiency. Selecting the right balance between cost, complexity, and precision is crucial for manufacturers.

If your application involves high-precision, multi-cavity, or material-sensitive molding, a multi-zone hot runner control system is the best choice. For simpler molds, fewer zones can deliver reliable results at lower investment.

At CNTOPower, we specialize in advanced hot runner temperature control systems designed for injection molding manufacturers and mold engineers. Our intelligent controllers deliver the perfect balance of accuracy, reliability, and efficiency.

Explore our product range or contact us today for expert advice on selecting the right system for your mold.

Email: sales@topower-controller.com

Number: 0086-13825218815