In modern injection molding, efficiency and precision are critical. Among the many mold design ...

Common Automotive Plastic Parts Made by Injection Molding

Introduction

Plastics are central to modern vehicle design — enabling lighter weight, integrated functions, and lower production cost at scale. For procurement teams and design engineers, knowing which parts are commonly produced by injection molding, what materials and process controls are required, and how to select suppliers can cut development time and reduce field risk. This expanded guide synthesizes practical part-by-part examples, design notes, production considerations, and common supplier qualification checkpoints.

Exterior components: what’s molded and why it matters

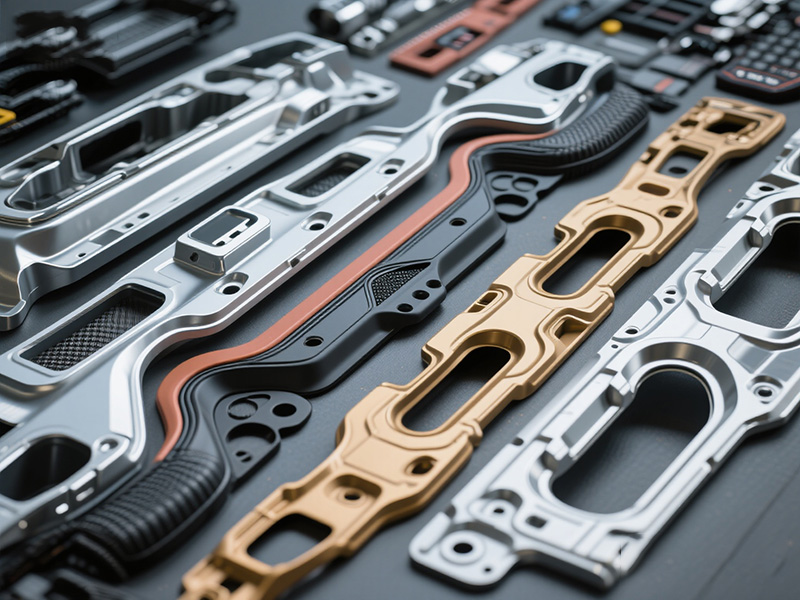

Exterior parts continue to be major uses of injection molding because plastics can deliver large, complex shapes with integrated mounting features while keeping weight low.

Bumpers & fascias: Typically molded from PP, TPO, or blends with impact modifiers. Design priorities are controlled wall-thickness, energy absorption, and paint adhesion. Parts often need welded seams or mechanically fastened subcomponents.

Mirror housings & grilles: ABS or PC/ABS for good surface finish and UV-stability. UV stabilisers and surface prep for painting are common spec items.

Trim profiles & badging: Short-run, high-cosmetic parts may use higher-grade resins or post-mold finishing to achieve OEM appearance.

Design tip: early DFM that aligns gate type, cooling channel layout, and texture specification prevents late surprises on cosmetic parts and reduces repaint or rework risk.

Lighting, lenses, and electrical housings — precision and material specs

Lighting systems use two distinct classes of molded parts:

Optical lenses: Polycarbonate (PC) for clarity; tight dimensional control is essential for beam alignment. Specification items include surface scratch resistance and post-mold coatings.

Housings and brackets: PC/ABS, PBT or glass-filled nylons, depending on thermal and structural loads. Electrical housings also carry flame-retardant and UL-rated requirements.

Procurement mandate: require material datasheets, UL/flammability ratings, and process controls (e.g., cavity pressure monitoring) in suppliers’ PPAP packages.

Interior modules & trim — aesthetics plus fitment

Interior components are judged by tactile feel, gap-and-flush tolerances, and long-term wear:

Instrument panels & large trims: Often ABS, PC/ABS or laminated assemblies. Techniques such as two-shot molding, foam backer, or skin-foaming provide soft-touch surfaces.

Door panels, center consoles, and bezels: Designed with integrated clips, snap-fits, and mounting bosses to reduce assembly steps.

Practical note: demand sample parts with your target texture and do a fit-up trial with mating metal components during pilot runs.

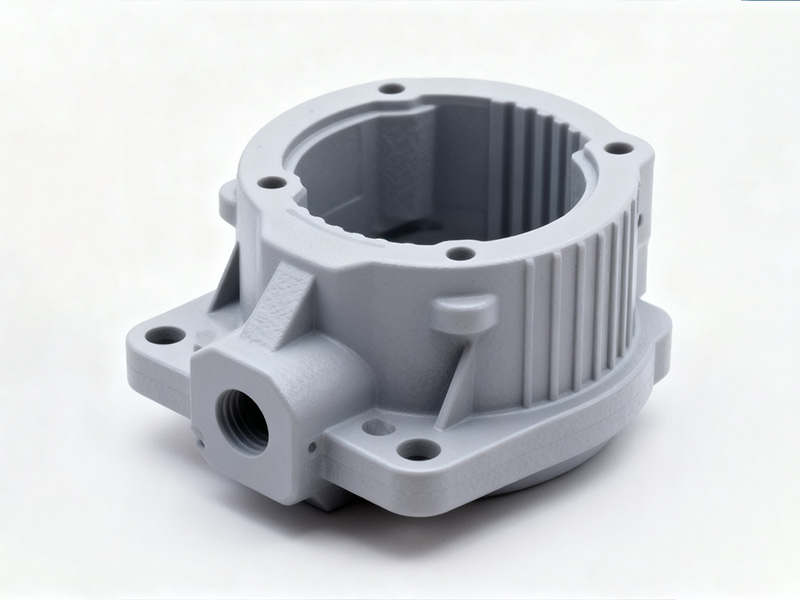

Structural and under-hood components — strength and heat resistance

Under-hood applications push material selection to engineered polymers:

Intake manifolds, mounting brackets, housings: Glass-filled nylon (PA), PPS, or reinforced polymers that resist heat, oil and mechanical load.

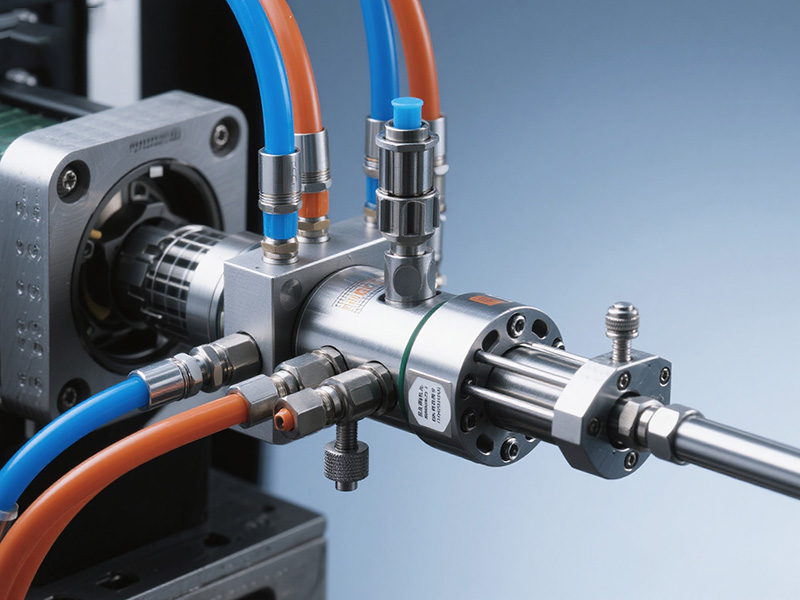

Cooling & fluid system parts: PBT and specially compounded polyolefins that handle thermal cycling and chemical exposure.

Engineering tip: for load-bearing parts, specify long-term creep testing and thermal aging data as part of supplier qualification.

Functional components & connectors — small parts, big requirements

Connectors, fuse boxes, sensor housings, and switch bezels are small but technically demanding:

Tight dimensional tolerances for reliable electrical performance.

Flammability ratings and dielectric strength testing are often contractual requirements.

PBT, PA, and specialized engineering grades are commonly used.

Ask suppliers for batch traceability of material and evidence of moulding consistency (cavity-to-cavity repeatability).

Common production challenges & mitigation strategies

DJmolding and experienced tier suppliers highlight several recurring issues that buyers should anticipate and mitigate early:

Material selection & testing: mismatched resin choice causes field failures. Mitigation: require mechanical, thermal, and chemical compatibility tests.

Tooling precision & durability: tooling errors create warpage, short shots, and cosmetic defects. Use hardened steel for high-volume molds and validated cooling designs.

Process variation: small changes in temp/pressure/cooling cause defects. Require SPC, in-line cavity pressure monitoring, and robust mold trial data in PPAP.

Environmental & regulatory constraints: flame retardancy, UV stability, and recyclability must be validated per spec.

Operational practice: insist on a structured validation plan — trial runs, CMM reports, mechanical tests, environmental cycles — before sign-off.

Supplier selection & qualification checklist

When choosing a molding supplier, procurement should evaluate:

Manufacturing capabilities: cavity count, machine sizes, automation, and clean room if needed.

Quality systems: IATF 16949, documented PPAP processes, SPC, and root-cause protocols.

Tooling expertise: in-house mold design & maintenance vs outsourced. Molds are often the single largest determinant of part quality.

Material traceability: the supplier must provide certificates, lot numbers, and change-control policies.

Prototype-to-production pathway: ability to quickly iterate on tooling and support pilot runs.

Sustainability practices: recycling use, waste handling, and material take-back programs (if required by OEMs).

Practical procurement tips (to reduce schedule & technical risk)

Start supplier engagement in the concept phase for DFM input.

Specify acceptance criteria that include cosmetic, dimensional, and functional tests — not just “visual accept.”

Require sample lots from different cavities and shifts to verify process stability.

Bind warranty and field performance KPIs into contracts.

Sustainability & circularity — what buyers should specify

OEMs increasingly demand recycled content or demonstrable recyclability. To avoid surprises, request mechanical property retention data for specified recyclate content and require supplier declarations on end-of-life options. Effective recyclability often demands design choices that avoid permanently bonded multi-material assemblies.

Conclusion & quick checklist

Injection molding serves dozens of typical automotive parts — exterior trims, lighting components, interior modules, under-hood parts, connectors, and more. Success depends not only on the right resin and mold design but on rigorous supplier qualification, process control, and clear acceptance criteria. Use the checklists above to structure RFQs, PPAP requirements, and supplier audits.

Conclution

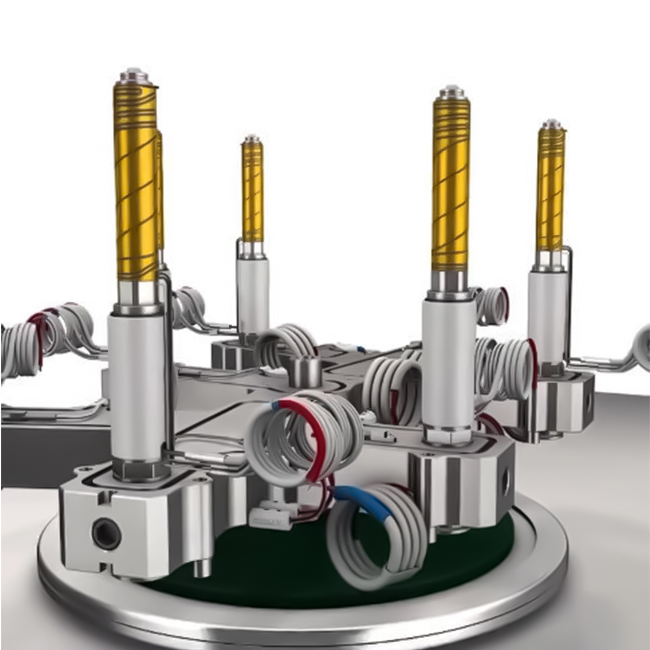

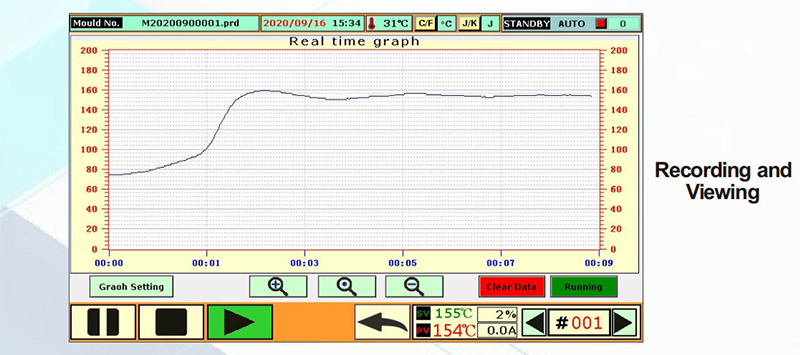

If your team is qualifying new injection-molded automotive parts or needs more consistent hot-runner and temperature control to reduce scrap and speed mold qualification, review Topower’s product range — modular TP01 hot-runner controllers, HY20 touch-screen controllers, time-sequential controllers, and accessories designed for multi-zone cavity control. These systems help stabilise melt temperature and reduce cycle variability during pilot and full production runs.