Choosing the right material is one of the most critical steps in automotive plastic injection ...

What Role Does the Hot Runner Play in Plastic Molds?

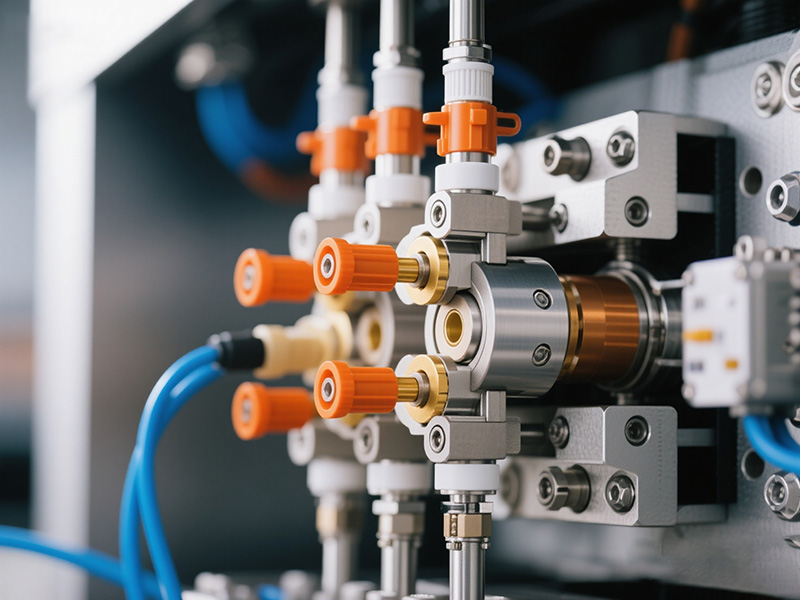

In modern injection molding, precision, efficiency, and consistency are critical. One essential component that makes this possible is the hot runner system. This advanced technology ensures that molten plastic flows evenly into mold cavities, improving part quality and reducing waste. But what exactly does a hot runner do in a plastic mold, and why is it so important for manufacturers today? Let’s explore its function, benefits, types, and design considerations in detail.

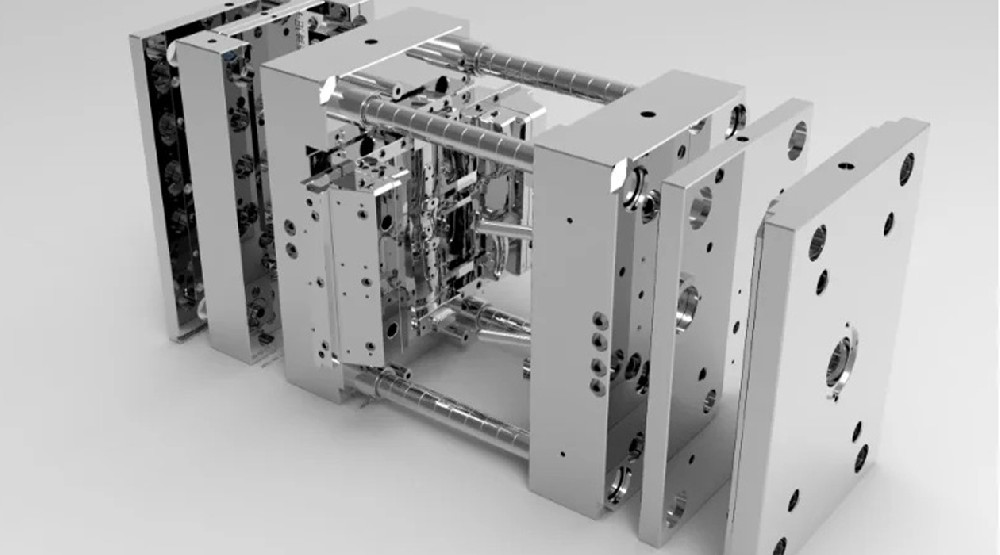

What Is a Hot Runner System in Injection Molding?

A hot runner system in injection molding is a network of heated components that keep the plastic material in a molten state as it travels from the injection unit to the mold cavities. Unlike cold runners, where excess plastic solidifies and must be removed, a hot runner keeps the melt flowing continuously.

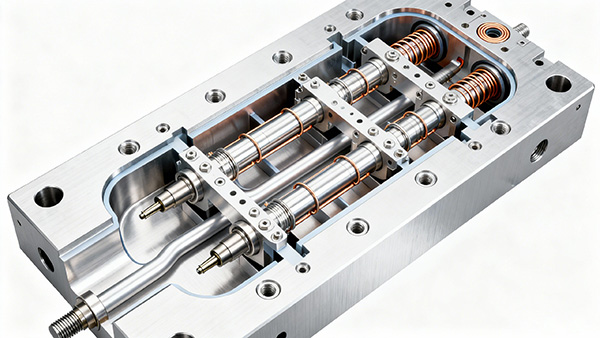

The system typically consists of:

Manifolds, which distribute the melt evenly to multiple cavities.

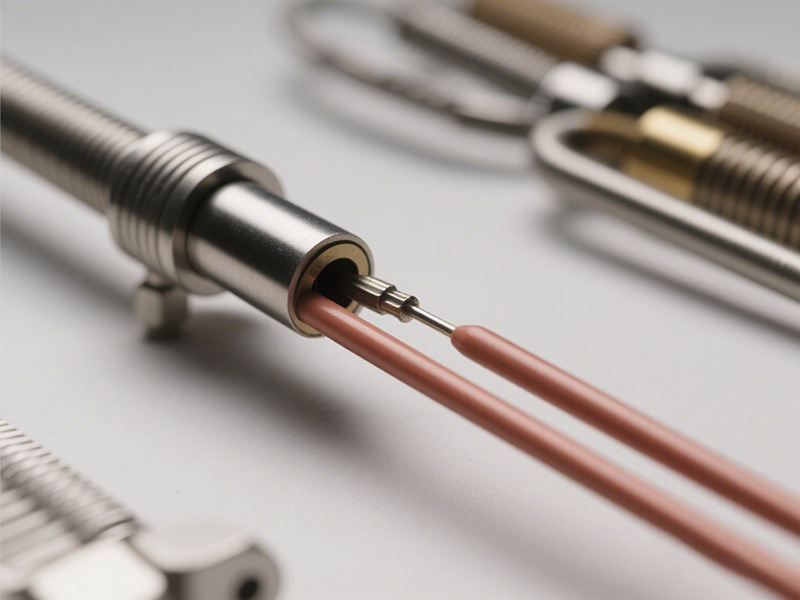

Nozzles, which inject the molten plastic into the cavity.

Heaters and sensors, which maintain the right temperature throughout the flow path.

Temperature controllers ensure stable and accurate operation.

In short, a hot runner system is the heart of a high-performance mold, directly affecting part quality and production speed.

How Does a Hot Runner System Work?

Understanding how a hot runner system works helps engineers and mold makers control quality and efficiency. The system maintains plastic at an ideal processing temperature through electrical heating elements. The melt travels from the injection machine through a heated manifold and nozzles into each mold cavity.

Traditional mold heating methods rely on external heating rods or plates, which can cause uneven heating and longer heating times. This results in low production efficiency.

In contrast, hot runner technology integrates heating channels directly inside the mold. By transferring heat energy directly to the core of the mold, it ensures faster and more uniform heating, greatly improving production efficiency.

Temperature precision is critical — even a small variation can cause flow imbalance or surface defects. That’s why a hot runner temperature controller for injection molding plays a key role. It regulates each zone’s temperature in real time to ensure consistent melt flow and minimize scrap.

CNTOPower provides reliable and intelligent Hot Runner Temperature Controllers that help manufacturers achieve stable production and precise molding performance.

Types of Hot Runner Systems in Injection Molding

There are several types of hot runner systems in injection molding, each designed for specific applications:

| Description | Typical Use |

| Simplified design without valve control, ideal for less complex parts. | Consumer goods, packaging |

| Uses mechanical or pneumatic pins to control flow; offers high precision and clean gate marks. | Automotive, electronics |

| Uses heated nozzle tips for fine control of melt flow. | Small, intricate components |

Hot Runner vs. Cold Runner System: What’s the Difference?

One common question among mold designers is the difference between hot runner and cold runner systems. Here’s a quick comparison:

| Feature | Hot Runner | Cold Runner |

| Material Waste | Minimal; no runners to trim | High runners must be removed |

| Cycle Time | Shorter | Longer |

| Initial Cost | Higher | Lower |

| Maintenance | Requires care | Easier to maintain |

Although hot runner systems involve a higher upfront cost, they significantly reduce long-term expenses by minimizing material waste and improving production efficiency.

Advantages of Hot Runner Systems in Plastic Molds

The advantages of hot runner systems in plastic molds are extensive and directly impact manufacturing performance:

Improved Production Efficiency

The hot runner delivers heat directly to the mold core through internal heating channels. This method ensures uniform and rapid heating, eliminating the uneven temperature issues seen in traditional heating rods or plates. As a result, molds reach processing temperature faster, shortening cycle time and improving production efficiency.

Enhanced Product Quality

Uneven heating in traditional molds often causes shrinkage, warping, or deformation of plastic parts.

Hot runner technology allows precise temperature control, keeping the melt uniform and preventing these common defects. The result is smoother surfaces, better dimensional accuracy, and overall improved product quality.

Raw Material Savings

In conventional molds, uneven temperature can cause excessive shrinkage compensation, requiring extra resin to maintain part quality. Hot runner systems maintain stable temperatures and consistent flow, thus reducing waste and saving raw materials.

Extended Mold Life

Uneven heating in traditional systems can also lead to mold surface wear or cracking. With precise and balanced heating, hot runner systems reduce mechanical stress on the mold, prolonging its service life and reducing maintenance costs.

The benefits of using hot runner molds in production are clear — higher output, better precision, reduced raw material waste, and longer mold life.

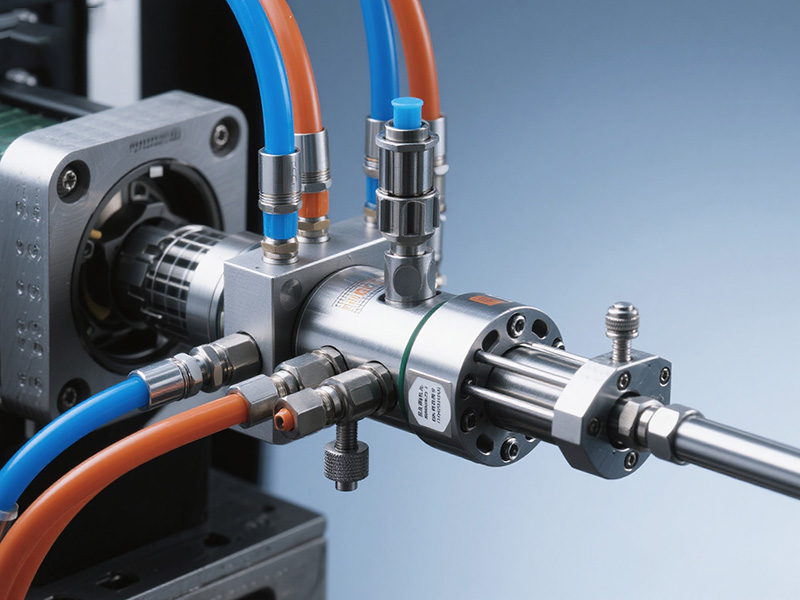

Hot Runner Temperature Controller for Injection Molding

Temperature control is the backbone of every efficient hot runner system. Without precise regulation, issues such as unbalanced flow, stringing, or part deformation can occur.

A hot runner temperature controller for injection molding ensures each heating zone maintains its optimal temperature, enabling consistent part quality.

CNTOPower specializes in advanced Hot Runner Temperature Controllers that support multi-zone control, rapid heating response, and compatibility with global mold standards like DME, YUDO, and HUSKY.

By integrating a CNTOPower controller, manufacturers can ensure that every part meets the highest standards of accuracy and performance.

Common Problems in Hot Runner Systems and Solutions

Even the best systems require proper maintenance. Some common problems in hot runner systems and solutions include:

Flow Imbalance: Caused by uneven heating; solved by recalibrating temperature zones.

Leakage or Blockage: Often from degraded resin; perform regular cleaning.

Temperature Drift: Caused by faulty sensors; replace or recalibrate controllers.

Preventive maintenance and using reliable control systems are the best ways to avoid costly downtime.

Hot Runner System Design Considerations

Effective hot runner system design considerations include:

Proper flow channel balance to ensure equal filling.

Thermal insulation to minimize energy loss.

Cavity layout optimization to prevent dead zones.

Material selection for nozzles and manifolds to ensure durability.

Designing a system with these elements in mind leads to longer mold life and more efficient production.

Best Hot Runner System Manufacturers for Injection Molds

Choosing a reliable supplier is as important as the design itself. The best hot runner system manufacturers for injection molds offer not just hardware, but expertise, technical support, and long-term value.

CNTOPower stands out as a trusted provider of Hot Runner Temperature Controllers, offering solutions that integrate seamlessly with a variety of mold designs. With advanced technology, global compatibility, and excellent customer service, CNTOPower helps mold makers achieve efficiency and reliability.

Conclusion

The hot runner system plays a central role in the success of modern plastic molds — from improving efficiency and part quality to reducing waste and extending mold life.

By understanding its structure, operation, and advantages, manufacturers can make smarter investment decisions that lead to long-term profitability and sustainability.

If you’re ready to enhance your injection molding performance, explore CNTOPower’s Hot Runner Temperature Controllers — engineered for precision, stability, and efficiency in every molding application.