Everything You Need to Know About Blow Molding

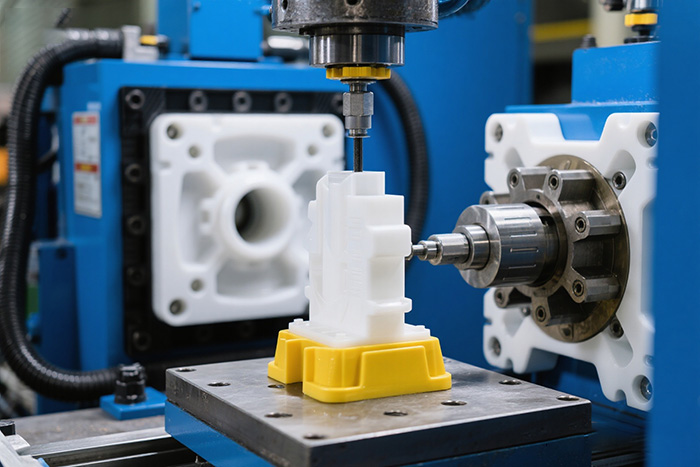

OverviewBlow molding is a manufacturing process used to form hollow plastic parts. It is used to make a wide range of containers – from water and soda bottles to oil jerry cans and large industrial d...

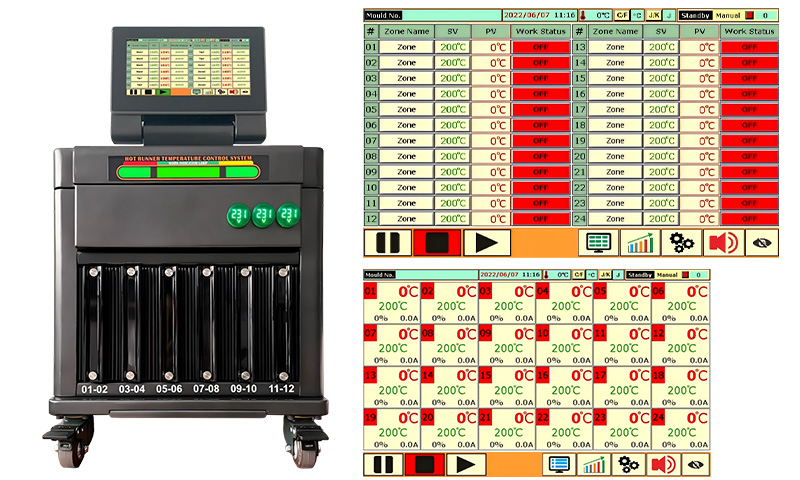

3 Core: Accuracy, Number Of Cavities, And Compatibility, When Selecting The Hot Runner Temperature Controller

In injection molding, temperature control plays a decisive role in determining product quality, cycle time, and mold longevity. Choosing the right hot runner temperature controller is ...

Custom Hot-Runner Temperature Control Solutions for Multi-Cavity Molds — Cut Debugging Time by 50%

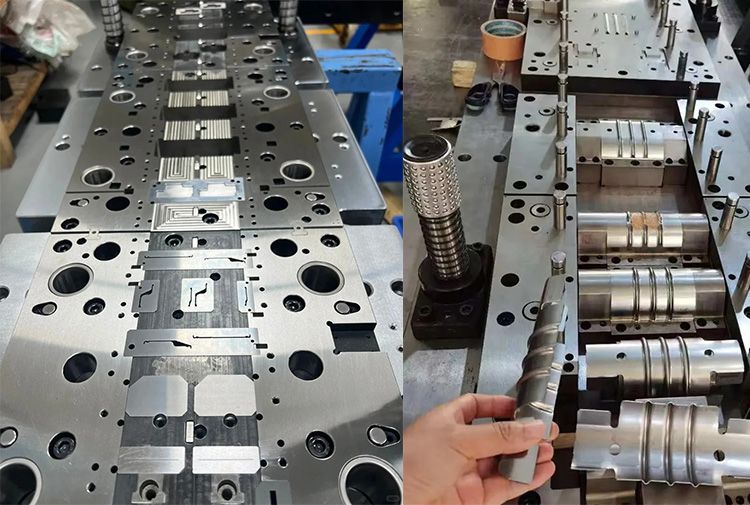

IntroductionMulti-cavity molds are the backbone of high-volume injection production: more cavities mean lower part cost and faster throughput. But more cavities also mean more potential for temperatur...

What Plastics Are Used For Handles — And Which Injection Molding Process Is Used?

As injection-molding engineers, when we design a handle part, we need to answer two key questions early:Which polymer/resin should I pick?Which molding process will deliver the part reliably, cost-eff...

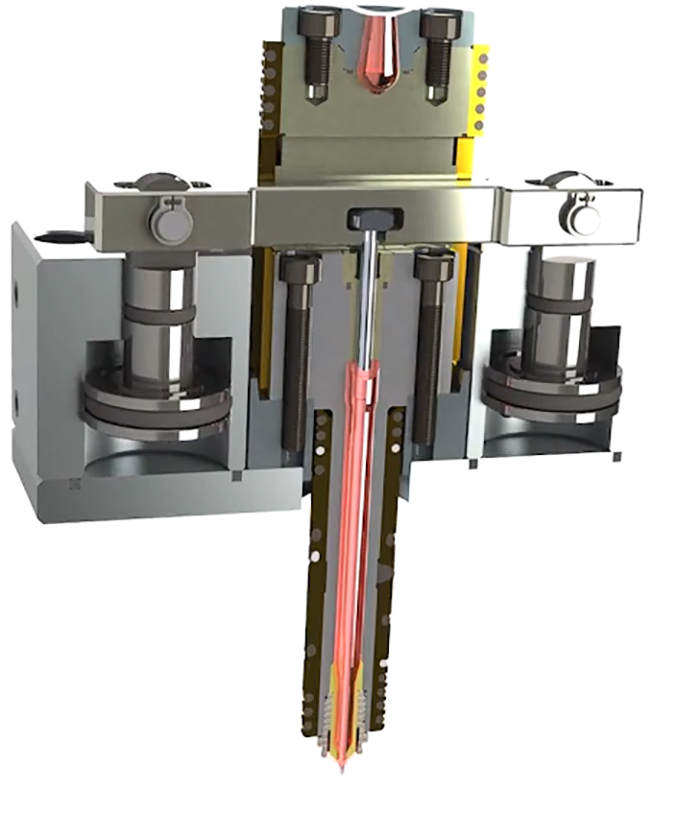

Top Benefits of Using Sequential Valve Gate Technology in Injection Molding

Sequential valve gate systems (also called sequential valve gating or sequential gating) let molders open and close individual hot-runner nozzles in a controlled sequence instead of letting all gates ...

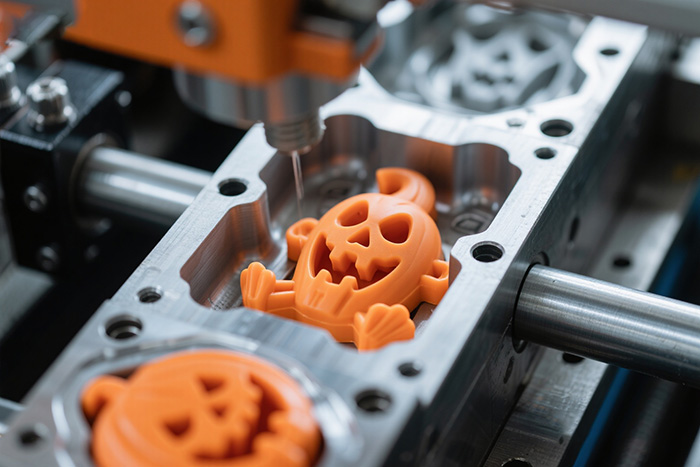

How Has Plastic Injection Moulding Contributed to Your Halloween Products?

IntroductionEvery Halloween season, shelves fill up with colorful, creative, and spooky products — from plastic Halloween pumpkins to Halloween plastic cups and plastic Halloween buckets. B...

Differences Among Injection Molding, Blow Molding, Blister Molding, and Extrusion Molding: A Complete Comparison Guide

When it comes to plastic manufacturing, choosing the right forming process is essential for achieving the perfect balance between quality, cost, and production efficiency. The four most widely used pl...

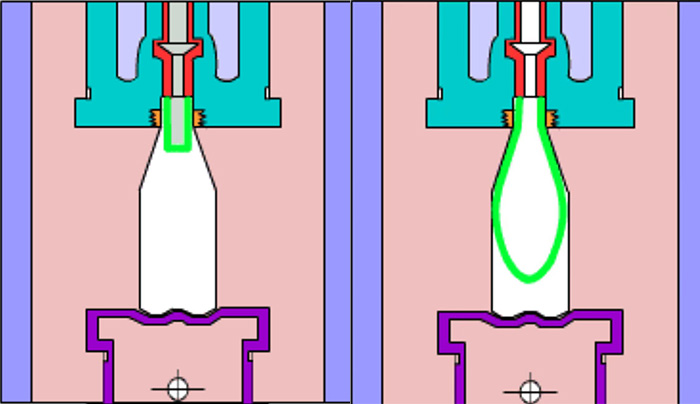

Everything You Need to Know About PET Bottles and Their Manufacturing Process

IntroductionEver wondered how a simple PET bottle goes from tiny resin pellets to the bottle you drink from every day?The process behind PET bottle manufacturing is a combination of chemistry, pr...