Hot Runner Controller Time Sequential Controller

Supply Power: AC220V/50-60Hz

Input Signal: It can receive active signal DC24V or AC220V and passive signal

(switch sign, no voltage), factory default is active signal which is DC24V or

AC220V input.If need passive signal,it should open the back cover and pull

out 2PIN plug J1 insert into J6(Passive signal input).

Notice: When input passive signal, there should no voltage of signal line,

otherwise it would damage the machine.

Output Power: Within DV24V(Pneumatic valve within 300mA per zone,hydraulic

valve within 1A per zone) or AC220V 1A.

Product Introduction

Time sequential controller is divided into hydraulic valve and pneumatic valve, which correspond to two different hot runner molds;

TMC model is mainly used in the needle valve hot runner injection system,

through the detection of the clamping signal of the injection molding machine,

according to the customer's needs of the mold injection can be adjusted to delay the clamping injection and different time off the needle valve,

accurately open and close the pneumatic needle valve nozzle valve pin, to make the injection product without the needle valve.

1. 1-8 independent channels, can be set according to actual needs

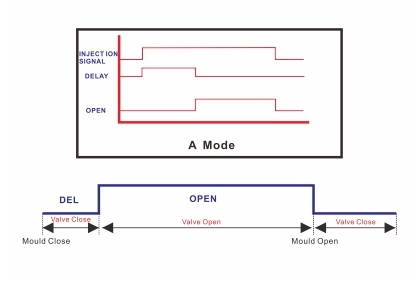

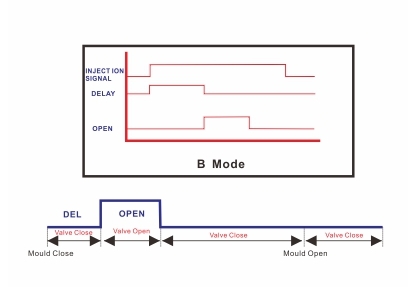

2. Two modes of operation (Mode A and Mode B), single/dual segment

3. Manual/automatic valve opening mode

4. Output signal 24/220V

Single-segment delay mode, when mould closing,

the needle valve will open after first segment delay time and will close needle after mould opens.

Two-segment delay mode, when mould closing,

the needle valve will open after first segment delay time and will close automatically after second segment delay time.