How to Select the Best Plastics for Injection Molded Automotive Parts

Choosing the right material is one of the most critical steps in automotive plastic injection molding. From interior trims to structural brackets and under-the-hood components, every resin direc...

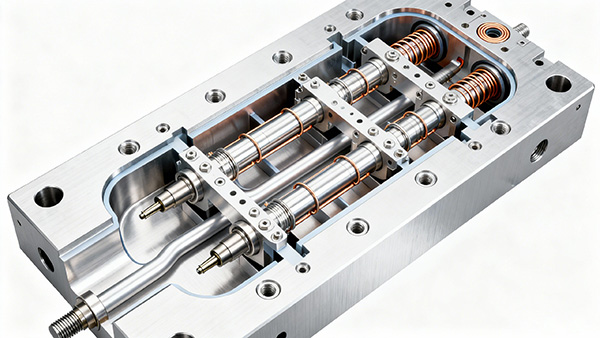

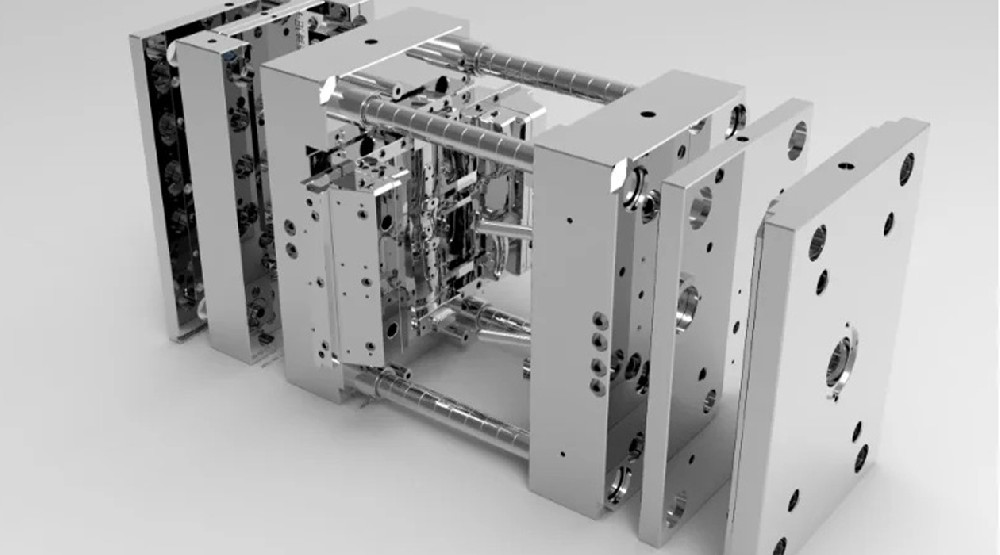

A Complete Guide to Hot Runner Molds: Advantages, Disadvantages, Key Technical Factors, and Application Fields

IntroductionAs injection molding technology continues to advance, hot runner molds have become a mainstream solution in global manufacturing. From thin-wall packaging to medical devices and consu...

Hot Runner vs Cold Runner: Which Injection Molding System Is Best for Automotive Components?

Automotive manufacturers rely heavily on plastic injection molding to produce lightweight, durable, and cost-efficient components. From interior trims and dashboard modules to clips, connectors, and f...

How To Choose The Right Material For Plastic Injection Molding(ABS、PP、PE、PC、PA、PBT)

Choosing the right material for plastic injection molding is one of the most important factors that determine the performance, durability, cost, and manufacturability of your parts. Whether you a...

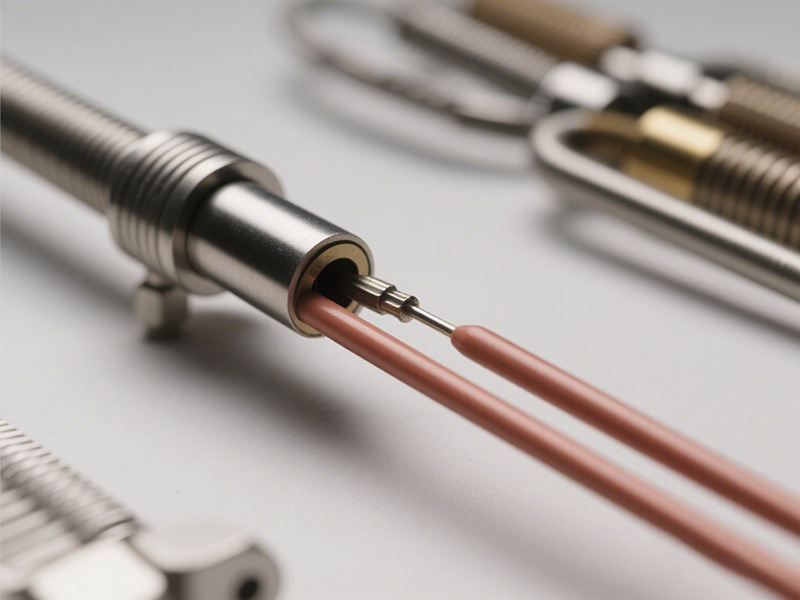

How to Diagnose and Fix Thermocouple Failures: A Practical Troubleshooting Guide

IntroductionThermocouples are trusted for industrial temperature measurement because they are rugged, fast, and reliable. However, harsh conditions—vibration, moisture, corrosion, and wiring issues—...

Open-Loop vs. Closed-Loop Temperature Control: What’s Best for Molders?

In modern injection molding, temperature stability is one of the most critical factors that determines part quality, cycle time, scrap rate, and overall process efficiency. And when it comes to temper...

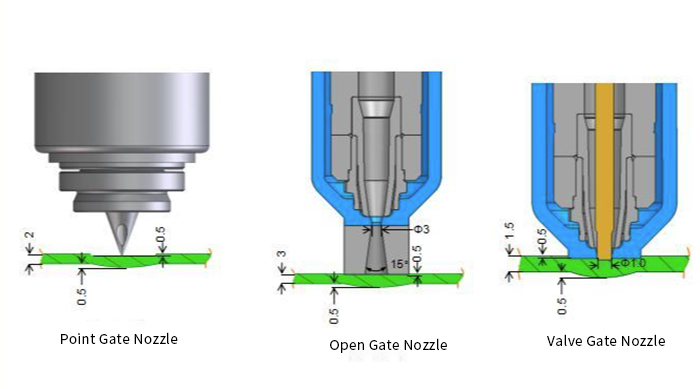

Open Gate vs. Valve Gate vs. Point Gate: How to Choose the Best Hot Runner Nozzle for Injection Molding

IntroductionIn a hot runner system, the open gate nozzle, valve gate nozzle, and point gate nozzle are the three most widely used injection molding gate types. Their differences lie mainly in gat...

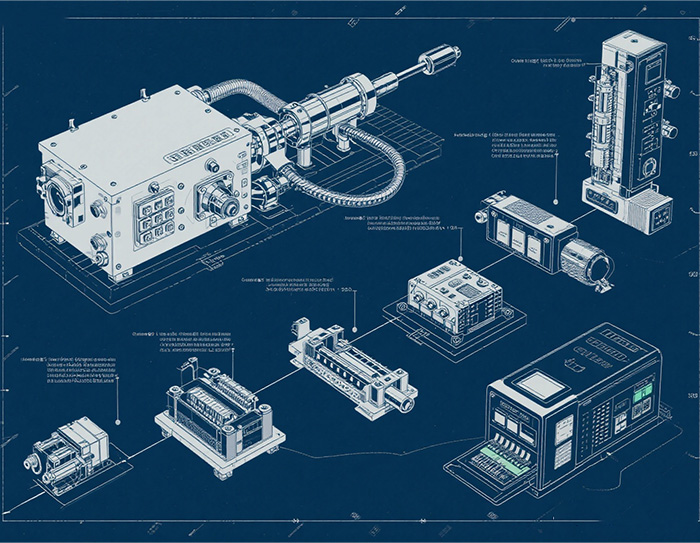

History of Hot Runner Temperature Controllers

IntroductionThe hot runner temperature controller is an essential component in modern injection molding systems. It ensures accurate and stable temperature control for the hot runner system, which dir...