Choosing the right material is one of the most critical steps in automotive plastic injection ...

3 Core: Accuracy, Number Of Cavities, And Compatibility, When Selecting The Hot Runner Temperature Controller

In injection molding, temperature control plays a decisive role in determining product quality, cycle time, and mold longevity. Choosing the right hot runner temperature controller is not just about cost—it’s about precision, efficiency, and reliability.

To simplify your decision-making process, let’s focus on the three most critical factors you should evaluate: Accuracy, Number of Cavities, and Compatibility.

Accuracy: The Foundation of Quality in Hot Runner Systems

Accuracy in temperature control determines how consistently molten plastic flows into the mold cavities. Even minor temperature fluctuations can lead to defects such as burn marks, color streaks, or short shots.

How Accurate Temperature Control Improves Injection Molding Quality

Precise temperature management ensures consistent resin flow and uniform product weight. When each heating zone maintains a stable temperature, the melt viscosity remains constant, leading to smoother filling and fewer defects.

PID Temperature Control for Hot Runner Systems

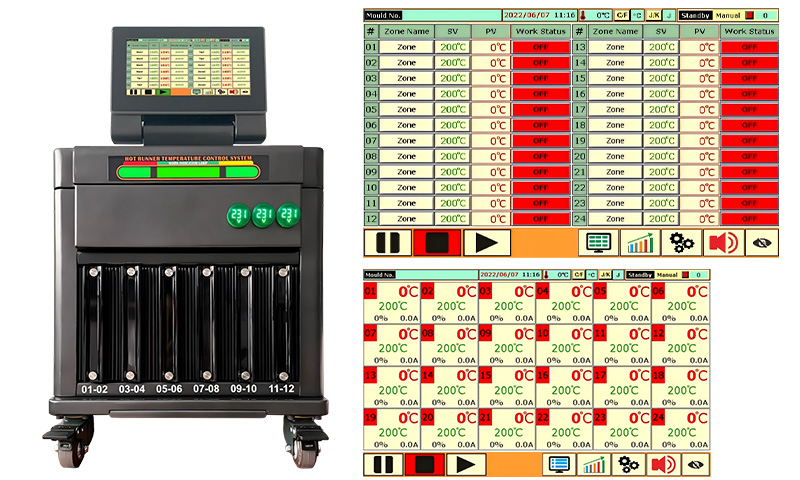

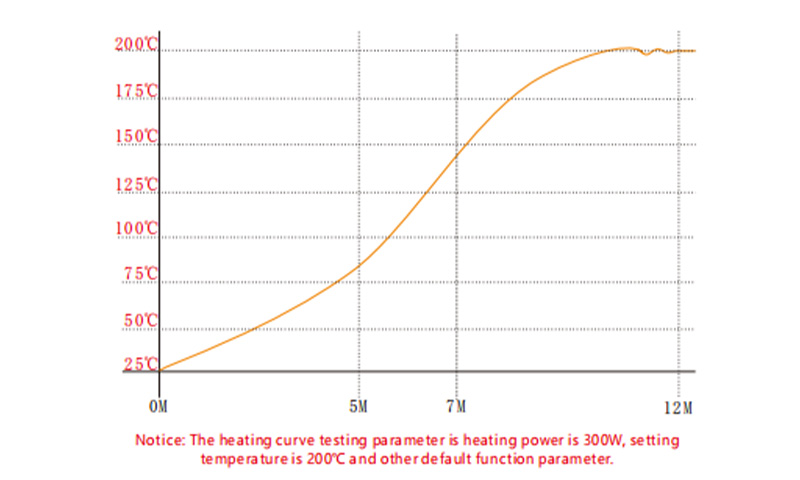

Modern digital hot runner temperature controllers use PID (Proportional–Integral–Derivative) algorithms to maintain tight temperature tolerances. High-end models—like touchscreen multi-zone controllers—can maintain accuracy within ±0.1°C, ideal for complex molds and high-precision components.

Tip: When evaluating accuracy, check whether the controller includes auto-tuning, overheat protection, and real-time monitoring functions. These features automatically adjust heater outputs to prevent temperature overshoot and extend heater lifespan.

Number of Cavities: Choose the Right Multi-Zone Controller

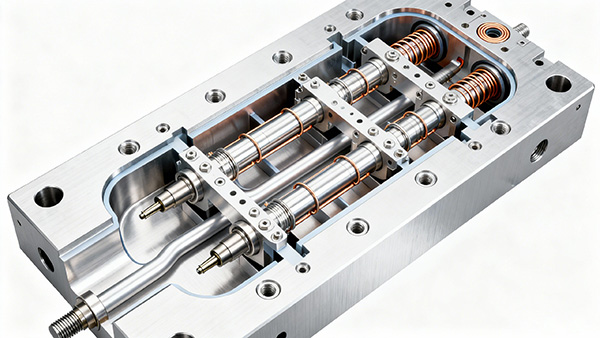

The number of cavities in your mold directly affects your temperature control requirements. Each cavity—or sometimes each nozzle—requires its own heating zone for independent control.

Why Multi-Zone Controllers Are Essential for Multi-Cavity Molds

For molds with multiple cavities, temperature uniformity across zones ensures that every part is filled evenly. A well-calibrated multi-zone hot runner temperature controller eliminates problems like flow imbalance and short shots.

Selecting the Right Hot Runner Controller by Cavity Count

Small molds (1–4 cavities): Use a compact 4-zone controller for cost efficiency.

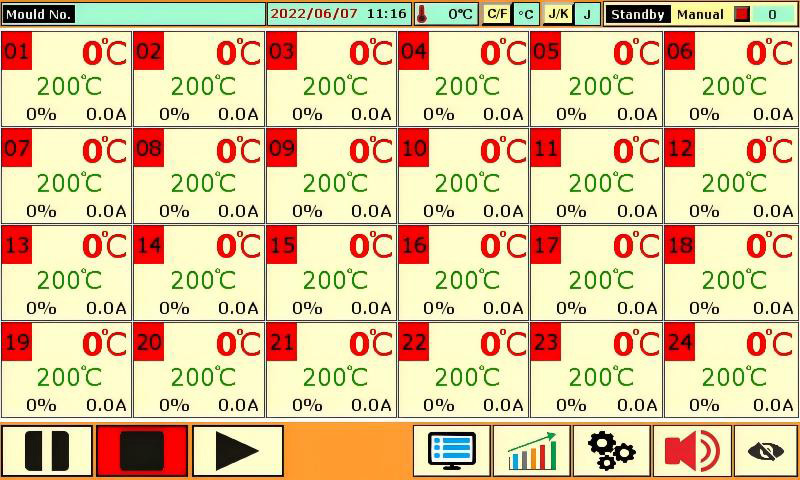

Medium molds (8–24 cavities): These require multi-zone temperature controllers with individual nozzle adjustments.

Large molds (32+ cavities): Opt for modular multi-zone systems that synchronize all zones in real time for uniform flow.

A well-chosen multi-zone controller also helps you:

Reduce setup time during mold changes

Simplify wiring and maintenance

Enhance productivity with simultaneous zone monitoring

Compatibility: Ensure a Perfect Fit with Your Hot Runner System

Not all controllers are universally compatible. Mismatched systems can cause unstable readings, heater burnout, or even production downtime.

Key Compatibility Features to Check Before Purchase

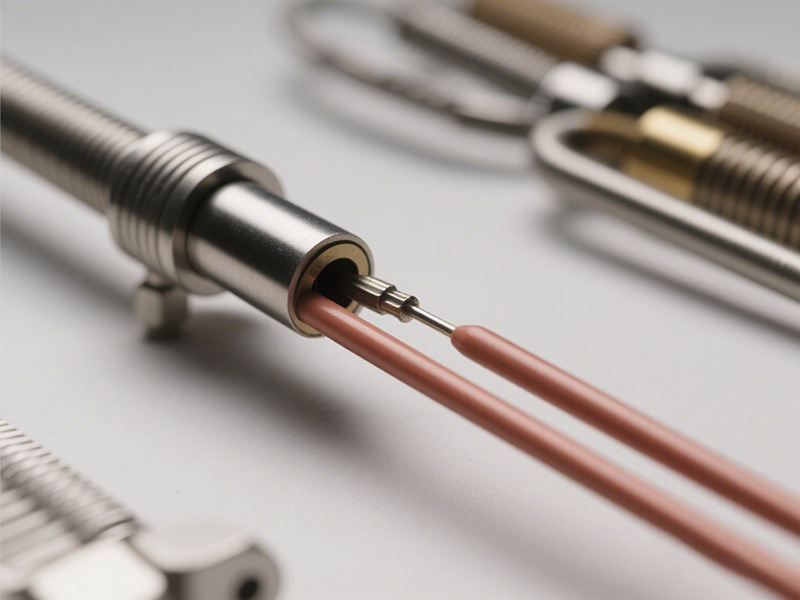

Connector Type: Match the controller plug configuration with your manifold or heater.

Thermocouple Type: Verify sensor compatibility (J-type or K-type).

Communication Protocols: Look for Ethernet, CAN, or RS-485 support for smart factory integration.

Power Rating: Ensure the controller can handle your total heater load safely.

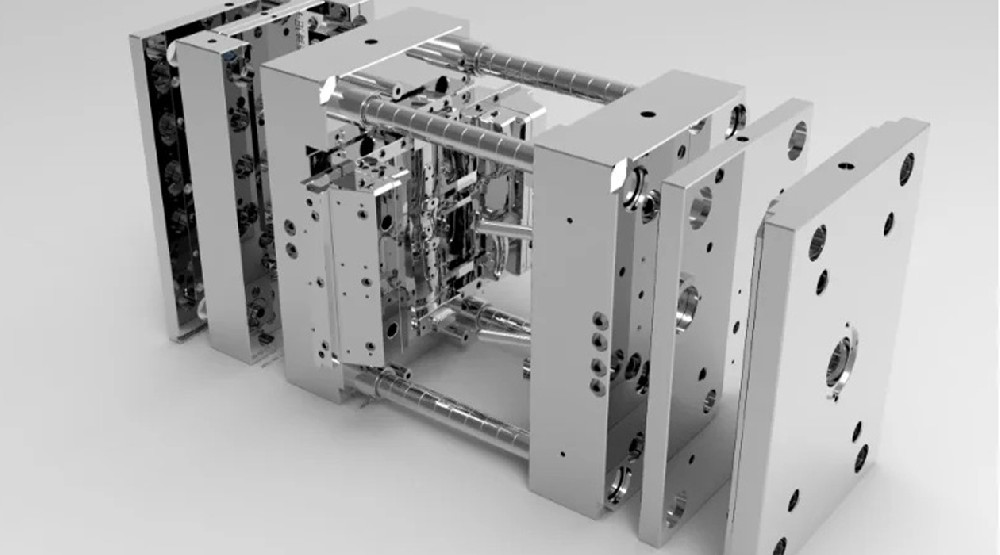

Universal Compatibility for Flexible Production

A highly compatible temperature control unit integrates easily with different mold bases, manifolds, and heating circuits. Modern touchscreen controllers often include auto zone detection, plug-and-play design, and user-friendly interfaces, minimizing setup errors and improving stability.

Tip: Choose a model offering universal input options and multi-language operation menus for global usability.

Advanced Features That Improve Hot Runner Performance

While the three core factors—accuracy, cavity number, and compatibility—are essential, advanced features can further optimize production efficiency.

Real-Time Monitoring and Data Logging

Smart controllers now offer temperature graphs, alarm history, and data recording, enabling better quality control and traceability.

Touchscreen Multi-Zone Control Interface

A touchscreen controller simplifies zone management, allowing quick temperature adjustments, easy troubleshooting, and clear visual feedback.

Safety and Protection Systems

Look for functions such as heater failure detection, sensor break alarms, and short-circuit protection, which can prevent mold damage and production downtime.

Why These 3 Factors Matter Together

The best hot runner temperature control system is one that achieves balance—high accuracy, sufficient zone capacity, and perfect compatibility. Ignoring any one of these elements can result in:

Unstable melt flow

Extended startup times

Uneven part quality

Increased maintenance costs

By evaluating all three together, you ensure:

Better molding efficiency

Reduced downtime

Longer hot runner lifespan

Conclusion: The Smart Choice for Efficient Molding

Selecting the right hot runner temperature controller is an investment in precision and productivity. Focus on these three pillars—Accuracy, Number of Cavities, and Compatibility—to achieve consistent results, reduced setup time, and smoother operations.

If you’re looking for a touchscreen multi-zone temperature controller designed for multi-cavity hot runner molds, check out our advanced systems here:

https://www.cntopower.com/HotRunnerTemperatureController/

Our controllers feature high precision PID control, real-time monitoring, and universal compatibility—helping you reduce debugging time by up to 50% and maximize your injection molding efficiency.