OverviewBlow molding is a manufacturing process used to form hollow plastic parts. It is used to mak...

Everything You Need to Know About Blow Molding

Overview

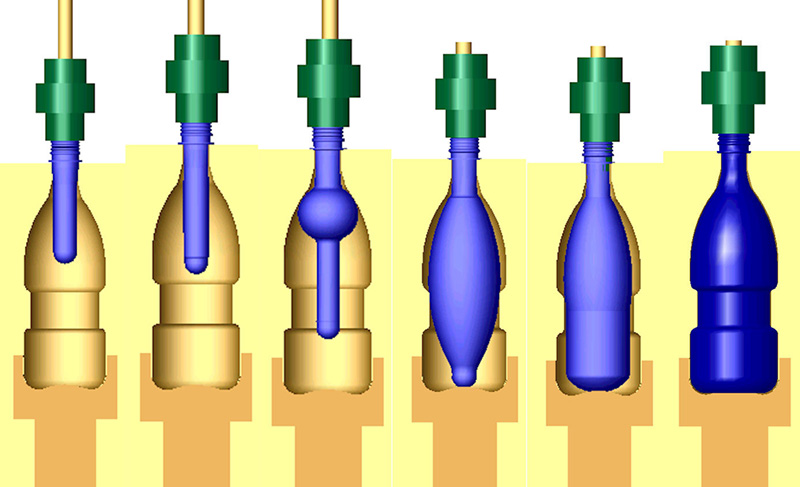

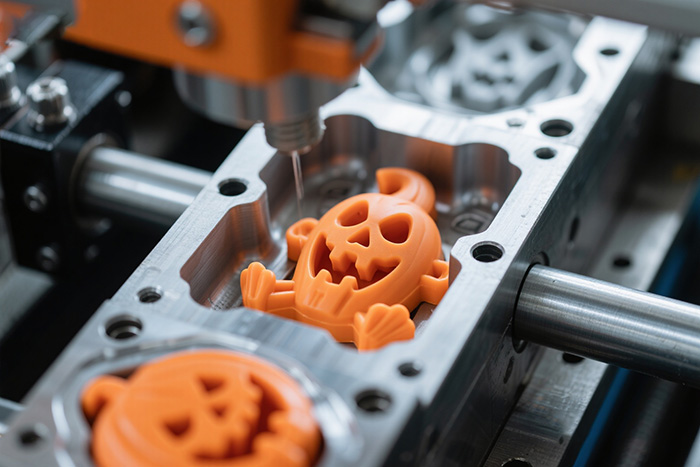

Blow molding is a manufacturing process used to form hollow plastic parts. It is used to make a wide range of containers – from water and soda bottles to oil jerry cans and large industrial drums. In blow molding, molten plastic is first formed into a tube (the parison), which is then clamped inside a split mold and inflated with air to take the shape of the cavity. This creates thin-walled, hollow products. The technique is inspired by glass blowing but applied to thermoplastics.

By contrast, injection molding fills a solid mold under high pressure and produces solid parts. Injection-molded parts tend to have complex geometries and tight tolerances, whereas blow-molded parts are always hollow. Because blow molding uses lower pressures and simpler (often aluminum) molds, it is generally less expensive per part when making large volumes of hollow items. In short, blow molding is ideal for hollow containers, while injection molding is used for solid or detailed components.

What Is Blow Molding?

Blow molding begins by melting plastic and forming it into a cylindrical parison. This parison is clamped between two halves of a mold. Compressed air is blown into the parison, inflating it so that the plastic presses against all sides of the mold cavity. As the air pressure inflates the parison, it conforms exactly to the shape of the mold. Once the plastic cools and solidifies against the mold walls, the mold opens, and the hollow part is ejected. In effect, the blow molding process “blows up” a soft tube of plastic like a balloon inside a rigid cavity, yielding bottles, tanks, and other hollow objects.

Types of Blow Molding

There are three primary blow-molding methods, each suited to different products:

Extrusion Blow Molding (EBM): Plastic is melted and extruded through a die into a continuous hollow tube (parison). The parison is then captured by closing the mold around it. Air is blown into the parison to inflate it into the shape of the hollow bottle or part. After cooling, the mold opens and the part is ejected. This method is commonly used for bottles, jugs, and industrial containers.

Injection Blow Molding (IBM): A preform or tube is first formed by injection molding onto a core pin. The core pin (with the preform attached) is then transferred into a blow mold. Air is blown into the preform, inflating it to the final hollow shape. Injection blow molding is less common (often used for small medical or single-serving bottles) but yields very accurate neck dimensions.

Injection Stretch Blow Molding (ISBM): Plastic is first injection molded into a rigid preform (with the bottle’s neck and threads). The preforms are then reheated and placed in a stretch blow mold. A rod stretches the softened preform vertically while air inflates it into the finished container. This biaxial stretching yields uniform wall thickness and is widely used for beverage bottles (PET, etc.).

Each method has its own machinery and tooling, and manufacturers choose based on the product’s complexity, material, and production volume.

Materials Used in Blow Molding

Blow molding typically uses thermoplastics that soften easily and solidify into durable containers. Common materials include:

High-Density Polyethylene (HDPE): The most widely used blow-molding plastic. HDPE’s strength-to-density ratio and chemical resistance make it ideal for everything from shampoo bottles and milk jugs to industrial drums and fuel tanks.

Low-Density Polyethylene (LDPE): Softer and more flexible than HDPE. LDPE is used in squeeze bottles, flexible bottles, and applications requiring stress-crack resistance.

Polypropylene (PP): Similar to HDPE but stiffer and more heat-resistant. PP is often chosen for applications needing higher temperature performance (e.g. dishwasher-safe containers) and very good chemical resistance.

Polyvinyl Chloride (PVC): PVC is available in rigid and soft grades. The soft PVC formulations are used in blow molding for items like flexible bellows, tubing, and some medical device components.

Polyethylene Terephthalate (PET): A polyester commonly blow molded for clear bottles, especially in the beverage industry. PET preforms can be injection or stretch-blow molded into soda and water bottles.

Polystyrene (PS): Used for rigid packaging (e.g., some caps, containers, and cases). PS is inexpensive but brittle, so it’s chosen only when toughness is not critical.

Thermoplastic Elastomers (TPE): Rubbery thermoplastics (e.g,. Santoprene) can also be blow molded, for applications like flexible covers or automotive bellows.

In general, blow molding is compatible with most common thermoplastics. In practice, polyethylene grades (HDPE, LDPE), polypropylene, PET, PVC, and some rubber-like TPEs dominate the industry.

Common Applications of Blow Molding

Blow molding produces a vast array of hollow plastic products used in everyday life and industry:

Consumer Packaging: Water, soda, and milk bottles; detergent and shampoo bottles; jugs and fuel cans.

Automotive Parts: Plastic fuel tanks, coolant and washer fluid reservoirs, ducting and air intake manifolds.

Industrial Containers: Large drums, chemical containers, water storage tanks, and industrial totes.

Household Appliances: Water reservoirs and detergent tubs in washing machines and dishwashers.

Medical and Safety: Blow-molded spray bottles, sanitizer containers, and some pharmaceutical containers.

Toys and Recreation: Plastic balls, toy blocks, kayaks, and other hollow play items.

Others: Coolers, traffic cones, large pallet boxes, and more.

In summary, any hollow plastic part can potentially be made by blow molding – from small bottles to large industrial tanks. Its strength in high-volume production makes it ubiquitous in packaging and automotive applications.

Blow Molding vs Injection Molding

Blow molding and injection molding are both high-volume plastic-forming processes, but they have distinct strengths and weaknesses.

Advantages of Blow Molding

Built-in Hollow Shape: Blow molding directly produces a single, hollow part in one operation – something that injection molding cannot do without complex cores. Complex hollow containers (e.g. a bottle with a narrow neck) are made easily by blow molding.

Lower Tooling Cost: Blow molds are simpler (often made of aluminum or simple steel) and operate at low pressure, so mold costs are much lower. As one industry guide notes, blow molding tooling can be performed at lower pressures with less expensive equipment.

Fast Cycle Times: Blow molding machines can run very quickly for many container shapes. The process requires only blowing and cooling, so cycle times tend to be short. The Topower blog highlights that blow molding has “faster cycle times” compared to injection.

Good for Large/Thick Parts: Blow molding can produce large-volume parts (like drums and tanks) more easily than injection, because blow machines can accommodate tall molds and extrusion volumes without extreme pressure.

Less Waste: Unlike multi-piece assembly, blow molding usually makes one-piece containers. Although trim scrap (flash) must be trimmed, there is no need to fuse multiple shells as in rotational molding or assemble separate injection-molded halves.

Efficient Material Use: For thin-walled containers, blow molding uses less plastic per part than a comparably thick injection-molded part.

Disadvantages of Blow Molding

Limited to Hollow Shapes: By design, blow molding only makes hollow parts. Solid or complex solid-geometry parts (gears, housings, thick brackets) cannot be done by blow molding.

Wall Thickness Control: Uniform wall thickness is harder to achieve. Gravity and parison sag can cause uneven walls, and blow molding inherently has some thickness variation. Injection molding gives much tighter dimensional control.

Lower Precision and Detail: Blow-molded parts typically have rougher surface finishes and lower dimensional tolerances than injection-molded parts. Fine details (threads, logos, complex textures) are less sharp in blow molding.

Secondary Operations: Blow-molded parts usually have a “flash” along the mold split that must be trimmed off. They may also require additional machining or welding for complex assemblies.

Limited Material Range: Although many thermoplastics can be blow molded, the range of materials (and colorants/additives) is narrower than injection molding. Very high-performance engineering polymers are rarely blow molded.

Advantages of Injection Molding

High Precision and Complexity: Injection molding can produce very intricate, solid parts with tight tolerances and fine surface finishes. The Topower blog notes injection molding offers “high precision and surface finish” and is suitable for “complex geometries”.

Wide Material Selection: Injection molding handles almost any thermoplastic (including filled and engineering plastics). It can even mold thermosets and thermoplastic elastomers. Blow molding, by comparison, mainly uses simpler resins like PE and PP.

Multi-Cavity Production: A single injection mold can have multiple cavities to produce many parts per cycle. This parallelism boosts throughput if you need thousands or millions of parts.

No Flash (Usually): Injection molds use tight-fitting cores and cavities. Finished parts generally require no or minimal trimming.

Versatility: Injection machines can run insert molding, overmolding, or multi-material molding. Parts can have threads, logos, and features molded in.

Disadvantages of Injection Molding

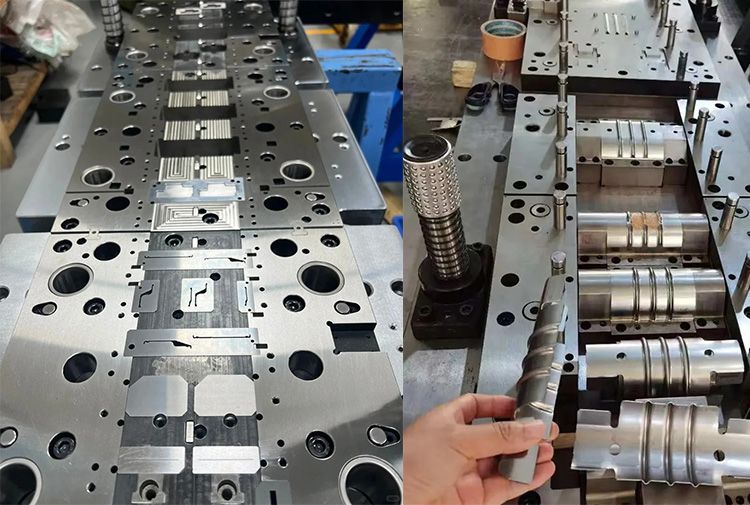

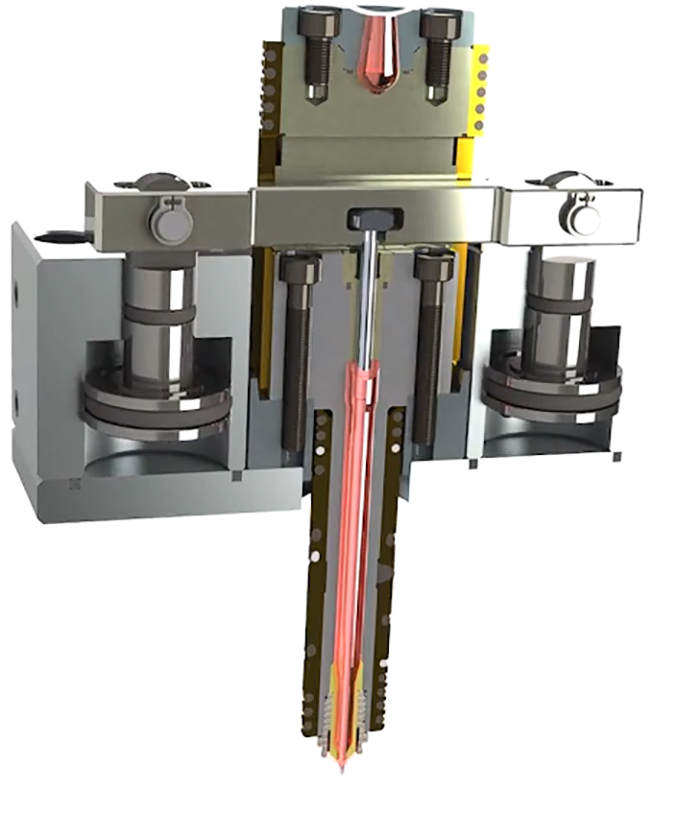

High Tooling Cost: Injection molds are large, complex steel tools with sophisticated cooling/heating channels. They cost much more to design and build. The Topower blog table shows injection molding’s disadvantages as “High mold cost” and “Longer development time”.

Expensive Equipment: Injection molding machines have heavy hydraulic or electric systems to inject plastic at high pressure. As one source notes, injection molding requires heavy-duty hydraulic rams to pressurize the plastic. This makes injection machinery more expensive and energy-intensive.

Longer Lead Times: Because of mold complexity, injection molding usually has longer lead times from design to production. Prototyping may require separate (e.g., 3D-printed) parts until the mold is ready.

Not for Thin-Walled/Bulky Parts: Very thin-walled or very large hollow parts are challenging for injection molding. (For thin walls, injection can warp or overpack, and for large sizes, the machine tonnage becomes impractical.)

Single-Material Limitation: While blow molding can produce hollow parts with complex geometry, injection molding might require assembling multiple pieces for complex hollow shapes.

Cost Comparison: Injection vs. Blow Molding Molds

When comparing mold costs, blow molding molds are generally much cheaper than injection molding molds. Blow molds are simpler in structure, operate under lower pressure, and are often made from aluminum, which reduces manufacturing time and cost. In contrast, injection molds require higher precision, stronger steel, and complex cooling systems, resulting in significantly higher tooling costs and longer lead times.

Overall, blow molding offers a lower initial investment, while injection molding provides greater accuracy and durability for long-term, high-precision production.

Conclusion

Choosing between blow molding and injection molding depends on the part design and production needs. Blow molding is the economical choice for hollow, thin-walled containers – it “offers an economical solution for hollow items,” as noted by industry experts. It excels at high volumes of bottles, tanks, and similar parts. Injection molding, on the other hand, delivers high precision and supports intricate geometries. Injection molds cost more, but they can produce complex solid or hollow parts with fine detail and high repeatability.

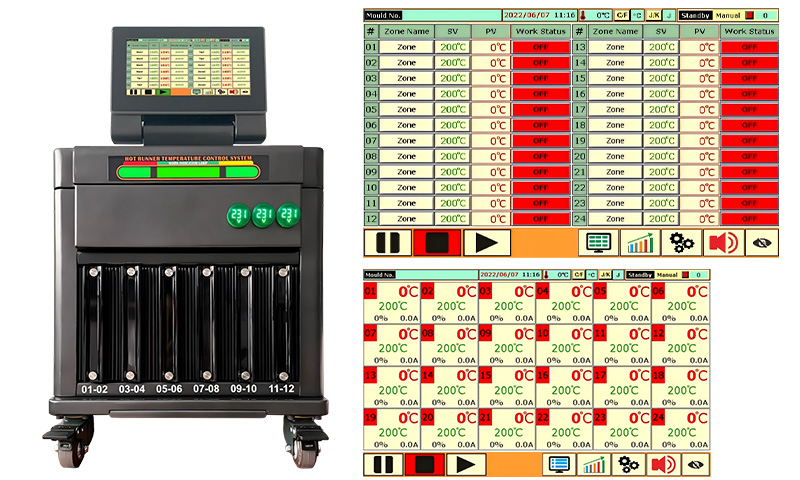

In practice, many manufacturers use both processes. For example, a PET water bottle might use injection stretch blow molding for the bottle (hollow) and injection molding for the cap (solid). Throughout, advanced technologies improve both processes. For instance, CNTOPower’s Topower brand provides hot runner temperature controllers that precisely regulate mold temperature – a critical factor for consistent injection molding. Such tooling innovations help injection molders maintain quality while producing large volumes.