When planning plastic part production, companies often face a critical decision: small run injection...

Top 10 Injection Molding Defects and How Hot Runner Temperature Controllers Prevent Them

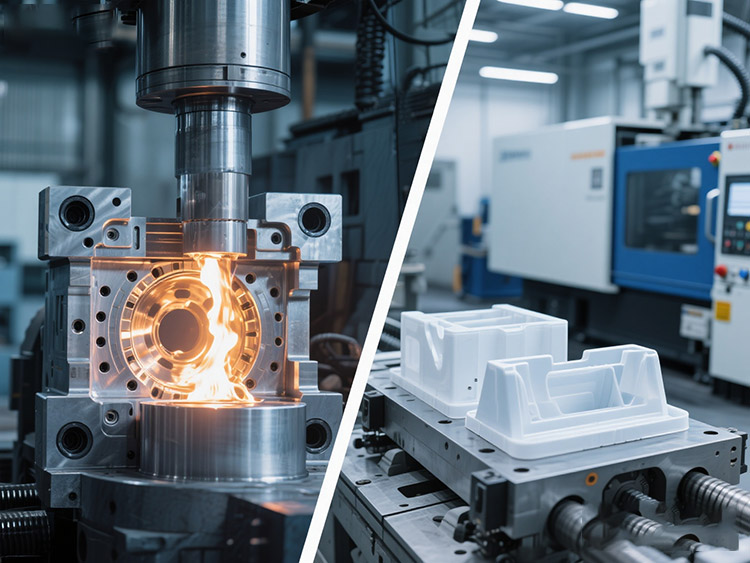

Injection molding is the backbone of the plastic packaging industry, producing everything from thin-walled containers to bottle caps at scale. However, one of the biggest challenges for injection molding engineers is dealing with injection molding defects that compromise part quality and increase scrap rates.

Defects such as short shots, sink marks, warping, burn marks, jetting, weld lines, flash, flow lines, delamination, and voids often occur due to poor temperature control in the molding process. This is where a hot runner temperature controller becomes an essential tool. By delivering precise multi-zone heating, PID regulation, and real-time monitoring, it stabilizes melt temperature and prevents common packaging defects before they occur.

In this article, we’ll explore the top 10 injection molding defects and explain how modern hot runner temperature controllers provide solutions that boost quality, reduce waste, and maintain compliance in the packaging sector.

Short Shots in Injection Molding and the Role of Hot Runner Temperature Controllers

Short shots occur when the cavity is not filled, leaving missing sections or thin walls. In the plastic packaging industry, this defect is particularly common in caps and closures where flow paths are long and thin.

Cause: Resin freezes too quickly or flow resistance is too high.

Temperature factor: If the hot runner temperature controller fails to keep the melt hot enough, plastic viscosity increases, and the flow stalls before the cavity is full.

Solution: multi-zone temperature controller ensures every nozzle maintains proper melt temperature, preventing freeze-off and achieving complete fill.

By using a reliable controller, engineers can minimize short shots and reduce scrap in high-volume packaging production.

Sink Marks in Packaging Parts and How Temperature Control Solves Them

Sink marks are small depressions on the surface of thicker areas, such as ribs or bosses. They result from uneven cooling and shrinkage.

Cause: Inner material cools and contracts later than the outer layer.

Temperature factor: High or unstable melt temperature prolongs cooling, leading to sinks.

Solution: hot runner temperature controller maintains stable and uniform melt flow, reducing uneven shrinkage and ensuring smooth surfaces.

This is critical for packaging items like cosmetic containers, where visual appeal is just as important as structural performance.

Warping in Plastic Packaging and the Need for Temperature Stability

Warping occurs when parts twist or bend after ejection due to uneven cooling. Thin-walled packaging, like trays and lid, is especially prone to this defect.

Cause: Unequal cooling rates in different sections of the mold.

Temperature factor: Poorly balanced hot runner zones create thermal gradients.

Solution: A PID-controlled hot runner temperature controller ensures each nozzle stays at the correct setpoint, so all areas cool uniformly.

With precise control, packaging engineers can reduce distortion and ensure parts remain flat and functional.

Burn Marks in Injection Molding and How Hot Runner Controllers Prevent Them

Burn marks appear as black or brown discoloration on parts, usually near gates.

Cause: Resin overheating or trapped air igniting.

Temperature factor: Overheated hot runner zones degrade plastic, causing burns.

Solution: Modern hot runner controllers have safety alarms and thermocouple monitoring. They immediately shut down overheating zones and prevent degradation.

This feature is crucial in packaging where visual quality directly impacts consumer trust.

Jetting Defects and Gate Temperature Control in Packaging Molds

Jetting looks like wavy flow lines near the gate, caused by a high-velocity stream of resin solidifying too quickly.

Cause: High injection speed and cold gates.

Temperature factor: If the gate zone isn’t hot enough, the stream freezes prematurely.

Solution: A zone-specific hot runner temperature controller maintains higher temperature at gate nozzles, keeping the flow molten and eliminating jetting.

For packaging items with visible surfaces, eliminating jetting ensures a clean appearance.

Weld Lines and the Importance of Multi-Zone Hot Runner Control

Weld lines (knit lines) occur when two flow fronts meet but don’t fuse completely.

Cause: Melt streams converge at low temperature.

Temperature factor: Uneven heating between hot runner zones makes some streams cooler.

Solution: Multi-zone controllers balance temperatures so both streams remain hot enough to bond, strengthening the weld and avoiding visible seams.

This prevents weak spots in packaging products that must endure sealing and transportation stresses.

Flash in Injection Molding and Controlled Melt Temperature

Flash is excess plastic leaking out of the cavity at the parting line.

Cause: Excess pressure and overly low viscosity.

Temperature factor: Overheated resin flows too easily into mold gaps.

Solution: A fast-response hot runner temperature controller avoids overshoot, keeping melt viscosity optimal and preventing flash formation.

This control is vital for packaging parts requiring tight tolerances, such as bottle closures.

Flow Lines in Injection Molded Packaging and the Impact of Temperature

Flow lines are streaks or wavy patterns caused by inconsistent flow speeds.

Cause: Variations in melt temperature and flow front cooling.

Temperature factor: Uneven hot runner heating leads to flow irregularities.

Solution: With PID-regulated controllers, engineers maintain consistent melt temperature, eliminating flow lines and ensuring smooth packaging surfaces.

This results in visually appealing products that meet strict branding requirements.

Delamination and the Role of Stable Melt Temperature

Delamination appears as surface layers peeling off the molded part.

Cause: Contamination or poor bonding due to low melt temperature.

Temperature factor: Uneven heating can cause resin to solidify in thin layers.

Solution: Advanced hot runner controllers maintain steady melt temperature, preventing layered separation and ensuring part integrity.

This ensures packaging remains safe for food and pharmaceutical applications.

Voids in Injection Molding and How Temperature Controllers Reduce Them

Voids are air pockets trapped inside parts, weakening structural strength.

Cause: Rapid cooling or insufficient packing pressure.

Temperature factor: Low mold temperature causes premature skin solidification, trapping air inside.

Solution: A hot runner temperature controller keeps melt fluid longer, allowing air to escape and reducing void formation.

This is essential for packaging items like thick bottle caps, where voids could affect sealing.

Why Hot Runner Temperature Controllers Are Critical for the Plastic Packaging Industry

In packaging production, defects mean wasted resin, downtime, and higher costs. By using a precision hot runner temperature controller, engineers gain:

Multi-zone heating for uniform temperature distribution

PID control for real-time temperature accuracy

Safety features to prevent overheating and material degradation

Data logging to analyze and optimize processes

At Topower, our advanced hot runner temperature controllers are designed to help injection molding engineers in the packaging industry reduce defects, improve efficiency, and deliver consistent product quality.

Learn more about our solutions at and contact us today to find the right temperature control system for your molding needs.