Choosing the right material is one of the most critical steps in automotive plastic injection ...

Why Multi-Zone Hot Runner Temperature Controllers Are Essential for Large Mold Applications

In the fast-paced world of plastic packaging manufacturing, precision and efficiency are everything. From bottle caps and containers to trays and lids, large molds with multiple cavities make it possible to produce thousands of identical parts per hour. But running these complex molds successfully isn’t easy—especially when it comes to controlling heat.

That’s where multi-zone hot runner temperature controllers come in. For large molds and multi-cavity systems, these controllers are not just helpful—they’re essential. In this article, we’ll explore why they matter, the challenges they solve, and how Topower’s advanced multi-zone solutions can make all the difference.

What Is a Hot Runner System and Why Is Temperature Control Critical?

To understand why multi-zone temperature controllers are so important, let’s start with the basics.

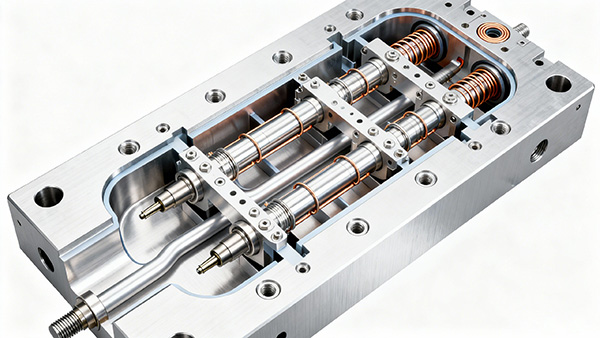

hot runner system is a heated assembly inside the mold that delivers molten plastic directly into each cavity. Unlike cold runners, which waste material by creating extra plastic channels, hot runners keep the plastic hot so it flows efficiently without leaving solid sprues behind. This reduces waste, improves cycle times, and saves costs—especially important in packaging, where speed and efficiency are critical.

However, the real challenge is temperature control. If the plastic inside the hot runner isn’t kept at the right temperature, it can degrade, burn, or solidify too early. This leads to defects like short shots, warping, or inconsistent part weight—problems no packaging manufacturer can afford.

Single-Zone vs. Multi-Zone: What’s the Difference?

Imagine trying to bake 32 cupcakes in one oven set to a single temperature—even though each cupcake tin is a different size and sits in a different spot. Some cupcakes would overcook, others would be undercooked. The same principle applies to molds.

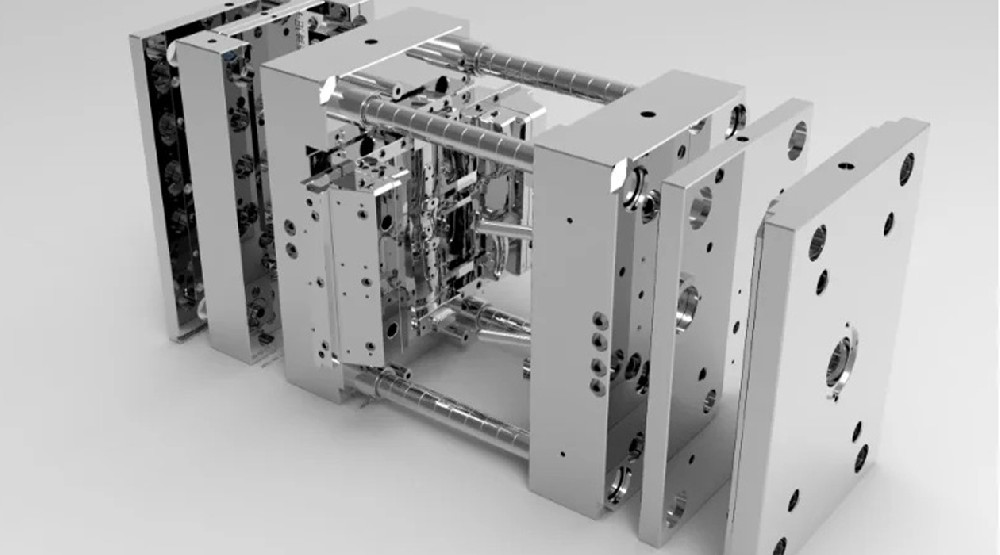

single-zone temperature controller heats the entire hot runner system to one set temperature. That might work for small molds with just a few cavities, but for large molds with 16, 24, or even 72 cavities, it’s a recipe for trouble.

Multi-zone controllers solve this by dividing the system into separate heating zones, each with its own sensor and control loop. This means every nozzle, manifold section, and gate gets the exact temperature it needs—automatically adjusted in real time. The result? Consistent melt flow, uniform cavity filling, and parts that meet exacting quality standards.

Why Large Mold Applications Need Multi-Zone Control

Precision Across Multiple Cavities

Large molds for packaging often have dozens of cavities. Each cavity should produce an identical part, but temperature variations can ruin this. Multi-zone controllers ensure every nozzle stays within ±1°C of the target temperature, so every cap, lid, or container looks the same.

Better Flow Balance

Uneven heating causes uneven flow. If one area is cooler, plastic thickens there and flows more slowly, leading to short shots. A hotter zone may cause flashing. Multi-zone control keeps the melt balanced, ensuring all cavities fill at the same time.

Reduced Scrap and Downtime

Defective parts cost money and time. With precise temperature control, manufacturers avoid defects like stringing, sink marks, or burnt material. This means less waste, higher yield, and fewer machine stoppages.

Energy Efficiency

Single-zone systems often overheat the entire mold to compensate for cold spots. Multi-zone systems power only what’s needed, saving electricity and extending heater life. In large-scale production, these savings add up fast.

Faster, Consistent Cycles

Consistent heat means predictable cycles. You don’t have to slow down to avoid defects. With stable temperatures, packaging lines can run at full speed, delivering higher throughput without sacrificing quality.

Challenges Without Multi-Zone Control

Without multi-zone control, packaging manufacturers face:

Warped or misshapen parts due to uneven cooling.

Dimensional variation between cavities.

Inconsistent part weight makes quality control harder.

Material degradation, especially for sensitive or recycled plastics.

Longer setup times and more trial-and-error adjustments.

In high-volume packaging, these problems mean lost profit and customer dissatisfaction. That’s why most modern plants won’t run large molds without multi-zone controllers.

How CNTOP’s Multi-Zone Solutions Deliver Performance

At Topower, we specialize in precision hot runner temperature control systems designed for demanding applications like packaging. Here’s how our products solve the challenges of large molds:

High Zone Capacity

Our HY20 Series Multi-Zone Temperature Controllers support 12-120 zones—perfect for big packaging molds like PET preforms and multi-cavity closure molds.

Modular Design

Our systems are modular, so you can start small and scale up. Need more zones for a new mold? Just add another module—no need to buy a whole new unit.

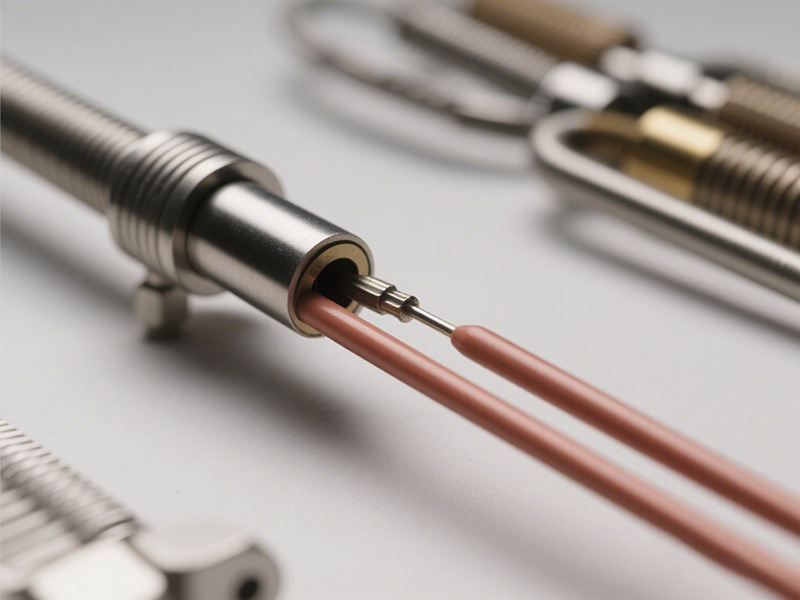

Advanced PID Control

Every zone uses PID (Proportional-Integral-Derivative) control with ±1°C accuracy for stable temperature. This maintains your melt consistency and eliminates common defects, such as stringing or short shots.

Touchscreen Interface

Our touchscreen controllers make setup easy. Operators can monitor all zones in real-time, adjust settings quickly, and even get alerts for thermocouple failures or out-of-range temperatures.

Energy Saving & Safety Features

Intelligent power control reduces unnecessary heating. Built-in diagnostics prevent heater burnouts, keeping your system running safely and efficiently.

The Future of Large Mold Manufacturing

In the packaging industry, where speed, precision, and cost-efficiency rule, multi-zone hot runner temperature controllers are no longer optional—they’re essential. They enable manufacturers to run large, complex molds confidently and competitively.

Ready to upgrade? Explore Topower's advanced hot runner controllers and find the perfect solution for your packaging applications. Contact us today.

for expert advice and a customized solution for your mold temperature control needs.