Choosing the right material is one of the most critical steps in automotive plastic injection ...

Thermocouple Types (J, K) for Hot Runners: How to Choose and Maintain

Introduction

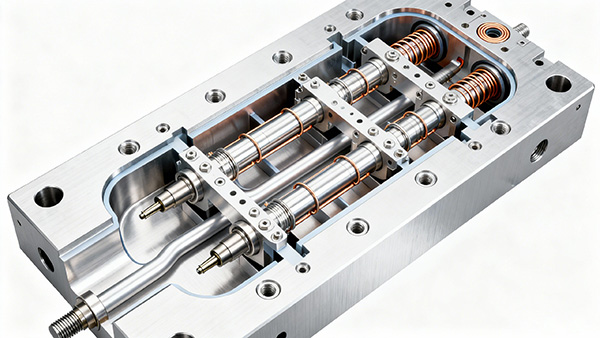

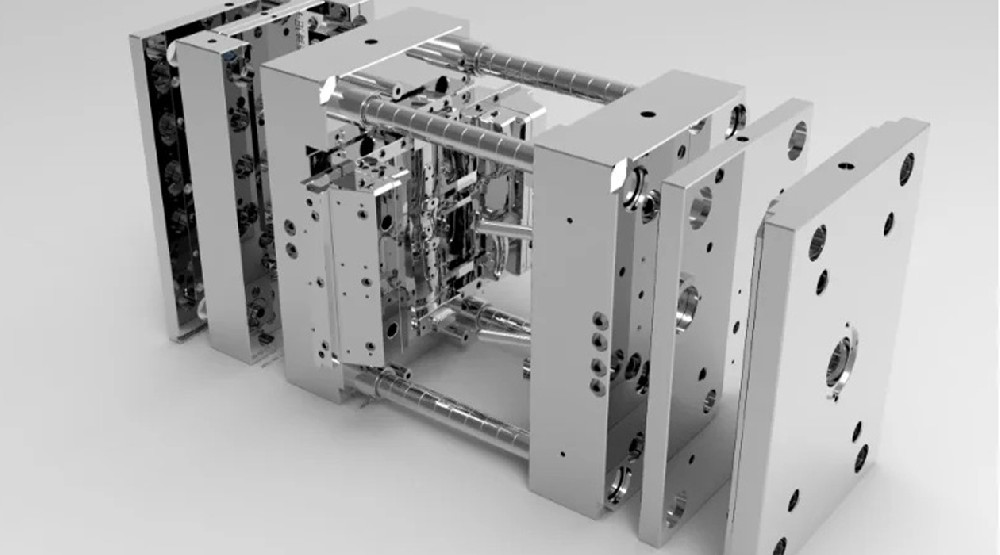

Hot runner systems are the backbone of modern plastic injection molding, ensuring precise temperature control, reduced material waste, and higher production efficiency. At the heart of temperature measurement in these systems are thermocouples—small but critical components that monitor and transmit accurate temperature data to the controller.

Among the various thermocouple types, Type J and Type K are the most commonly used in hot runner applications. But how do you decide which is right for your system? And once installed, how do you ensure they deliver reliable performance over time?

In this blog, we’ll explore the differences between Type J and Type K thermocouples, their pros and cons, selection criteria, and best practices for maintenance to extend their service life.

What Are Thermocouples in Hot Runner Systems?

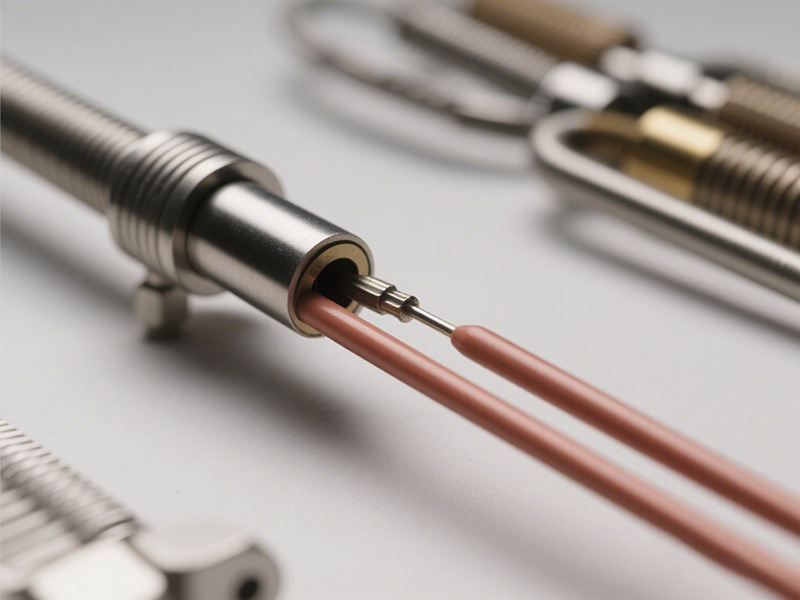

A thermocouple is a temperature sensor consisting of two dissimilar metal wires joined at one end. When the junction is exposed to heat, it generates a voltage that corresponds to temperature.

In hot runner systems, thermocouples are embedded near heaters to:

Monitor melt temperature.

Provide feedback to the hot runner controller.

Ensure consistent part quality by preventing overheating or underheating.

Without accurate thermocouples, even the most advanced hot runner controller cannot maintain stable mold temperatures.

Thermocouple Type J vs. Type K

Type J Thermocouples

Composition: Iron (positive) and Constantan (negative).

Temperature Range: 0°C to 750°C.

Accuracy: ±2.2°C or ±0.75%.

Advantages:

High accuracy in lower to mid-temperature ranges.

Cost-effective compared to other types.

Widely available and easy to replace.

Limitations:

Prone to oxidation at higher temperatures.

Shorter lifespan in humid or corrosive environments.

Type K Thermocouples

Composition: Nickel-Chromium (positive) and Nickel-Alumel (negative).

Temperature Range: -200°C to 1,260°C.

Accuracy: ±2.2°C or ±0.75%.

Advantages:

Wide temperature range, suitable for most molding applications.

More resistant to oxidation and corrosion.

Longer lifespan compared to Type J in demanding environments.

Limitations:

Slightly more expensive than Type J.

It can drift over time, requiring periodic recalibration.

How to Choose the Right Thermocouple for Hot Runners

When selecting between Type J and Type K, consider the following factors:

Operating Temperature:

If your hot runner system consistently runs below 750°C, Type J may be sufficient.

For high-temperature applications, Type K offers better reliability.

Environmental Conditions:

For humid or oxidizing environments, Type K is more durable.

Type J is better suited for controlled environments with stable conditions.

Accuracy vs. Cost:

Type J provides accurate readings at a lower cost.

Type K, though more expensive, delivers broader versatility and longer lifespan.

Compatibility with Controller:

Ensure your hot runner controller supports the selected thermocouple type.

Many modern controllers can handle both J and K.

Common Issues with Hot Runner Thermocouples

Even with the right thermocouple, problems can occur over time. Common issues include:

Signal Drift: Leads to inaccurate readings and poor temperature control.

Mechanical Damage: Caused by bending, pulling, or poor installation.

Oxidation/Corrosion: Especially with Type J in harsh conditions.

Wiring Failures: Broken connections or loose contacts can cause unstable temperature readings.

Maintenance Best Practices for Thermocouples

To maximize thermocouple performance and lifespan:

Regular Inspection

Check wires, insulation, and junctions for signs of wear or damage.

Replace any compromised thermocouples immediately.

Proper Installation

Avoid sharp bends or excessive pulling during installation.

Ensure the thermocouple is placed close to the heating element for accurate readings.

Calibration

Perform routine calibration to correct signal drift.

Document calibration intervals as part of preventive maintenance.

Environmental Protection

Use protective sheaths in corrosive or humid environments.

Ensure proper grounding to prevent electrical noise interference.

Spare Management

Keep spare Type J and Type K thermocouples in stock for quick replacement.

Label them clearly to avoid mix-ups during maintenance.

Best Practices for Thermocouple Maintenance

To maximize the lifespan of hot runner thermocouples:

Inspect regularly: Look for wear, corrosion, or broken wires.

Install correctly: Avoid bending cables and place sensors close to heaters.

Calibrate periodically: Prevent drift by calibrating every 6–12 months.

Use protective sheaths, especially in humid or corrosive environments.

Keep spares: Stock both Type J and Type K thermocouples for fast replacements.

Topower provides complete hot runner solutions, including controllers and thermocouples, ensuring that your production line runs smoothly without unexpected downtime.

Conclusion

Thermocouples may be small, but they play a critical role in hot runner systems. Choosing between Type J and Type K depends on your operating conditions, required temperature range, and cost considerations. With proper installation, regular calibration, and preventive maintenance, you can significantly extend their service life and ensure consistent part quality.

At Topower, we specialize in advanced hot runner temperature controllers designed to work seamlessly with both Type J and Type K thermocouples. Our solutions help manufacturers maintain stable process conditions, reduce downtime, and improve product quality.

Looking for reliable hot runner thermocouples and controllers? Contact Topower today to discuss your project needs.

FAQs about Thermocouple Types J and K

Can I replace a Type J thermocouple with a Type K?

Yes, if your controller supports both thermocouple types.

How often should thermocouples be calibrated?

Every 6–12 months depending on production intensity.

What’s the main difference between Type J and Type K thermocouples?

Type J is cost-effective and accurate for mid-range temperatures, while Type K offers broader range and durability.