Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

Injection Molding vs 3D Printing: Materials, Strength, Heat Resistance & Surface Finish

Introduction

When choosing a plastic manufacturing process, materials and performance often matter more than speed or initial cost. Two of the most widely used methods today—injection molding and 3D printing—serve very different purposes, even though they are sometimes compared as alternatives.

Injection molding is the backbone of mass production, delivering consistent quality and strong mechanical performance. In contrast, 3D printing, also known as additive manufacturing, excels in rapid prototyping and low-volume customization.

This article provides a materials- and performance-focused comparison of injection molding vs 3D printing, examining strength, heat resistance, surface finish, and real-world applications. By understanding how materials behave in each process, manufacturers and engineers can make more informed decisions when moving from prototyping to production.

What is 3D Printing?

3D printing is an additive manufacturing process that creates parts by building material layer by layer based on a digital 3D model. Unlike traditional manufacturing, which often removes material, 3D printing adds only what is required, making it ideal for complex geometries and fast iteration.

The main advantages of 3D printing include rapid design changes, minimal tooling requirements, and relatively low upfront costs. For early-stage product development, it allows engineers to validate form, fit, and basic function in a short time frame.

However, when evaluating injection molding vs 3D printing, it is important to note that material performance in 3D printing is often limited by layer bonding, printing orientation, and available material options.

Types of 3D Printing Technologies

Different 3D printing technologies offer different material properties and performance levels.

FDM (Fused Deposition Modeling)

FDM is the most common and cost-effective 3D printing method. It uses thermoplastic filaments such as PLA, ABS, and PETG.

Low equipment and material cost

Visible layer lines

Limited mechanical strength along the Z-axis

SLA / DLP (Resin-Based Printing)

SLA and DLP use liquid photopolymer resins cured by light.

Excellent surface finish and detail

Brittle mechanical behavior

Poor heat resistance compared to engineering plastics

SLS (Selective Laser Sintering)

SLS uses powdered nylon materials such as PA12.

Stronger and more isotropic than FDM

No support structures required

Higher cost, closer to injection molding performance

Among all options, SLS comes closest to injection molding in terms of material strength, but it still cannot fully match molded parts in consistency or scalability.

What is Injection Molding?

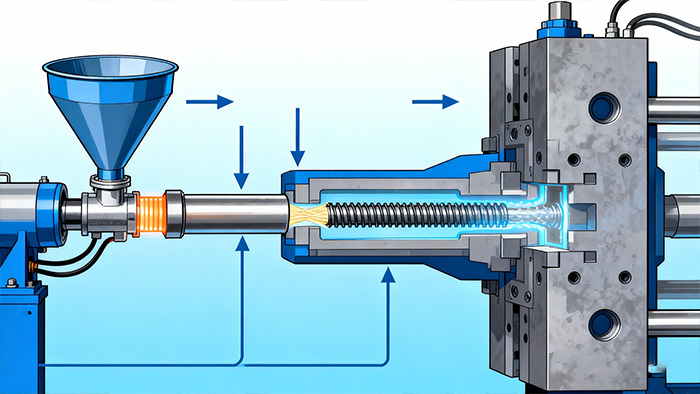

Injection molding is a high-volume manufacturing process in which molten plastic is injected into a precisely machined mold cavity under high pressure. After cooling, the solidified part is ejected with consistent dimensions and surface quality.

This process is widely used for producing durable, functional plastic parts across industries such as automotive, electronics, medical devices, and consumer products.

When comparing injection molding vs 3D printing, injection molding stands out for its ability to use advanced engineering plastics, reinforced materials, and fillers that significantly improve mechanical and thermal performance.

How Does Injection Molding Work?

The injection molding process follows a repeatable and tightly controlled cycle:

Material Melting – Plastic pellets are heated until fully molten.

Injection – The molten plastic is injected into the mold cavity.

Cooling & Solidification – The part cools under controlled conditions.

Ejection – The finished part is released from the mold.

The Role of Temperature Control and Hot Runner Systems

Precise temperature control is critical at every stage of injection molding. Inconsistent temperatures can lead to defects such as short shots, warpage, burn marks, and dimensional instability.

This is where professional hot runner temperature control systems play a vital role. Stable and accurate temperature regulation ensures:

Uniform melt flow

Consistent part quality across cavities

Reduced material waste

Faster cycle times

CNTOPower specializes in advanced hot runner temperature controllers designed for multi-cavity molds and high-precision injection molding applications. By maintaining accurate thermal balance throughout the mold, CNTOPower systems help manufacturers achieve higher repeatability, improved surface quality, and long-term production stability—advantages that 3D printing simply cannot offer at scale.

Overview of Materials Used in Injection Molding

Injection molding supports a wide range of industrial-grade thermoplastics, including:

ABS

Polypropylene (PP)

Polycarbonate (PC)

Nylon (PA6 / PA66)

POM (Acetal)

These materials can also be reinforced with glass fiber, mineral fillers, or flame-retardant additives. The result is superior mechanical strength, chemical resistance, and thermal stability.

Because molded parts are isotropic, their strength is uniform in all directions—an important advantage when evaluating injection molding strength vs 3D printing.

Overview of Materials Used in 3D Printing

3D printing materials are more limited in comparison.

Common options include:

PLA (easy to print, low heat resistance)

ABS and PETG (moderate strength)

Nylon (PA12 for SLS)

Photopolymer resins

While these materials are suitable for prototyping and short-term use, they often fall short in demanding environments. Layer adhesion and print orientation significantly affect final part strength.

This difference becomes critical when transitioning from design validation to functional production.

Mechanical Strength Comparison

Injection Molding Strength Characteristics

Injection molded parts offer:

High tensile and impact strength

Consistent mechanical properties

Excellent fatigue resistance

These characteristics make injection molding ideal for load-bearing and long-life components.

3D Printing Strength Characteristics

3D printed parts often show:

Directional weakness along layer lines

Reduced impact resistance

Variation between builds

When comparing the strength of injection molding vs. 3D printing, injection molding delivers superior and more reliable mechanical performance.

Heat Resistance & Thermal Performance

Injection molding materials such as PC, PA, and PPS can withstand high operating temperatures, making them suitable for automotive and electrical applications.

Most 3D printing materials soften or deform at relatively low temperatures. Even high-performance resins and nylons struggle to match the heat resistance of molded engineering plastics.

This makes injection molding the preferred choice for parts exposed to sustained heat or thermal cycling.

Surface Finish & Post-Processing

Injection Molding Surface Finish

The mold itself defines surface finish in injection molding. Parts can be produced with:

High-gloss finishes

Matte or textured surfaces

Minimal or no post-processing

3D Printing Surface Finish

3D printed parts typically show visible layer lines and require sanding, coating, or polishing. These additional steps increase cost and production time.

From an aesthetic and functional standpoint, injection molding provides a production-ready finish straight from the mold.

Material Performance vs Application Scenarios

| Application Stage | Recommended Process |

| Concept & design validation | 3D Printing |

| Functional testing | 3D Printing / SLS |

| Low-volume production | Case-dependent |

| Mass production | Injection Molding |

| End-use industrial parts | Injection Molding |

Many manufacturers adopt a hybrid approach: 3D printing for early prototypes, followed by injection molding for final production.

How to Choose the Right Process Based on Material Requirements

Key factors to consider include:

Operating temperature

Mechanical load

Surface quality expectations

Production volume

Long-term cost efficiency

If your product requires high strength, heat resistance, and consistent quality at scale, injection molding is the logical choice. With reliable temperature control systems like those from CNTOPower, manufacturers can further optimize quality, efficiency, and repeatability.

Conclusion

The comparison between injection molding and 3D printing ultimately comes down to material performance and application needs. While 3D printing excels in speed and flexibility, injection molding remains unmatched in strength, thermal stability, surface quality, and scalability.

By understanding these material differences—and by leveraging professional temperature control solutions—manufacturers can confidently move from prototyping to mass production with consistent, high-quality results.

>>Hot runner temperature controller