In modern injection molding, precision is not optional—it is fundamental. At the center of th...

Applications of Hot Runner Temperature Controllers for Different Plastic Materials

In plastic injection molding, accurate and stable temperature control plays a critical role in product quality, cycle time, and mold lifespan. As the core component of a hot runner system, a hot runner temperature controller must be precisely matched to the processing characteristics of different plastic materials.

Each plastic resin has its own melting temperature range, thermal stability, and sensitivity to temperature fluctuations. Therefore, understanding how hot runner temperature controllers perform with different materials is essential for engineers, mold designers, and procurement professionals.

This article explores the applications of hot runner temperature controllers across common injection molding materials, highlighting key control requirements and selection considerations.

Why Different Materials Require Different Temperature Control

Plastic materials vary significantly in:

Melting temperature range

Thermal stability

Sensitivity to shear and overheating

Crystalline or amorphous structure

Tolerance to temperature fluctuation

Using the same temperature control strategy for all materials often leads to issues such as:

Stringing and drooling

Material degradation or burning

Short shots or uneven filling

Poor surface finish and inconsistent mechanical properties

This is why high-precision, multi-zone hot runner temperature controllers have become standard in modern injection molding.

Applications of Hot Runner Temperature Controllers by Material Type

PP and PE (Polypropylene & Polyethylene)

Material Characteristics

Low melting temperature

Good thermal stability

Relatively tolerant to temperature variation

Temperature Control Requirements

Focus on overall temperature stability

Prevent overheating that may cause drooling

Even temperature ramp-up during startup

Recommended Controller Features

Standard PID temperature control

Single-zone or basic multi-zone controllers

Moderate response speed

ABS (Acrylonitrile Butadiene Styrene)

Material Characteristics

Moderate thermal stability

Sensitive to overheating

High surface quality requirements

Temperature Control Requirements

Tight control of temperature differences between manifold and nozzles

Avoid localized overheating to prevent discoloration or burn marks

Minimize temperature fluctuation during production

Recommended Controller Features

High-accuracy PID control

Real-time temperature monitoring and alarm functions

Soft start function to protect heaters

PC (Polycarbonate)

Material Characteristics

High processing temperature

High melt viscosity

Extremely sensitive to temperature stability

Temperature Control Requirements

Insufficient temperature causes short shots

Excessive temperature leads to material degradation

Precise multi-zone synchronization is critical

Recommended Controller Features

High power output capability

Accurate multi-zone temperature control

Thermocouple break detection and rapid fault protection

PA / Nylon (Including Glass-Filled Grades)

Material Characteristics

Hygroscopic material

Glass fiber significantly affects flow behavior

Sensitive to both shear and temperature

Temperature Control Requirements

Accurate nozzle temperature control to reduce stringing

Independent adjustment for different heating zones

Fast temperature response to process changes

Recommended Controller Features

Multi-zone independent control (8, 16 zones or more)

Fast-response control algorithms

Designed for continuous high-load operation

PET, PBT and Other Engineering Plastics

Material Characteristics

Narrow processing temperature window

Crystallization behavior is highly dependent on temperature

High dimensional stability requirements

Temperature Control Requirements

Long-term stable temperature control

Extremely small temperature deviation between zones

Prevent temperature drift that affects part dimensions

Recommended Controller Features

Industrial-grade high-stability temperature controllers

Real-time monitoring with data logging capability

Communication interfaces for system integration

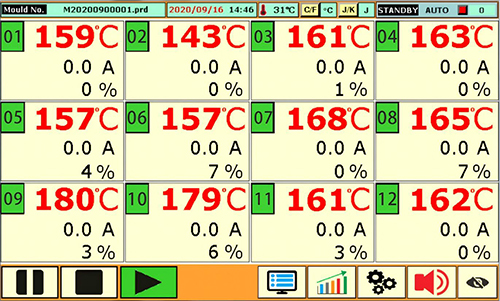

Advantages of Multi-Zone Hot Runner Temperature Controllers

As mold designs become more complex, single-zone control is no longer sufficient. Multi-zone hot runner temperature controllers offer clear advantages:

Independent control of each nozzle and heating zone

Reduced temperature deviation across the hot runner system

Improved part consistency and surface quality

Lower scrap rate and reduced setup time

These benefits are significant in automotive, electronics, medical, and packaging applications.

How to Select the Right Hot Runner Temperature Controller

When choosing a hot runner temperature controller, consider the following factors:

Temperature control accuracy (±0.1°C or ±0.5°C)

Number of control zones (6–120 zones)

Output power and load capacity

Safety protections (over-temperature, short circuit, thermocouple failure)

User interface (modular controller or touchscreen controller)

The more temperature-sensitive the material, the higher the performance requirements for the controller.

Conclusion

Different plastic materials place very different demands on hot runner temperature control. Selecting a hot runner temperature controller that matches the material’s processing characteristics is essential for achieving stable production, consistent part quality, and long-term mold reliability.

As injection molding continues to move toward higher precision and automation, high-accuracy, intelligent, multi-zone hot runner temperature controllers will remain a key foundation for advanced manufacturing.