Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

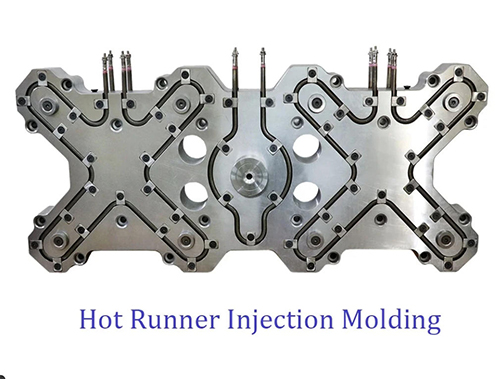

Which Injection Molds Should Use Hot Runner Systems?

Hot runner systems have become an essential technology in modern injection molding, especially for high-efficiency and high-quality production. However, not every injection mold requires a hot runner system. Due to higher initial costs and technical complexity, hot runner systems are best suited for specific mold types and production scenarios.

This article explains which injection molds should use hot runner systems, based on mold structure, production volume, material type, and quality requirements—helping you make the right technical and economic decision.

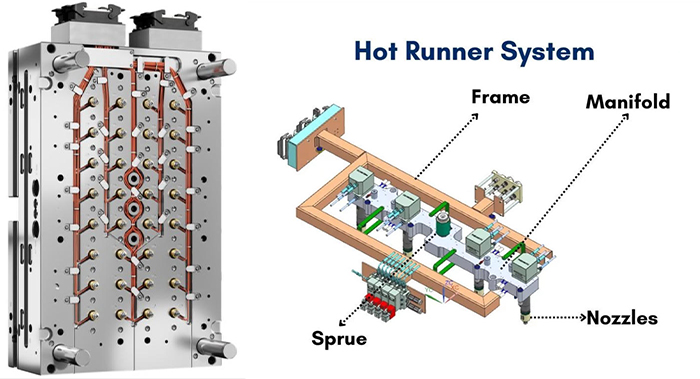

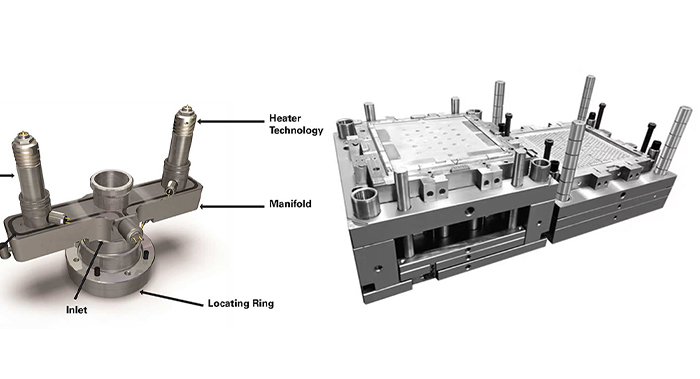

What Is a Hot Runner System?

A hot runner system keeps the plastic melt continuously heated inside the manifold and nozzles, eliminating solidified runners after each cycle. Compared with cold runner systems, hot runners offer:

No runner waste

Shorter cycle times

More stable melt flow

Improved part consistency

Injection Mold Types That Should Use Hot Runner Systems

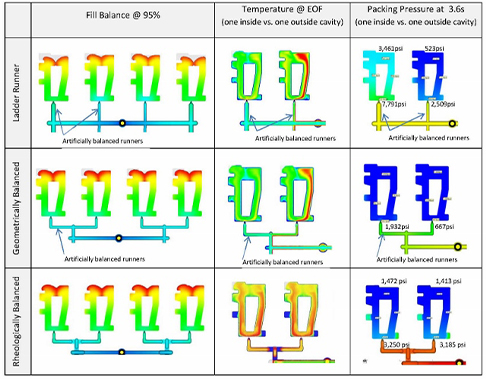

1. Multi-Cavity Injection Molds

Typical Characteristics

8, 16, 32 cavities or more

Strict consistency requirements

Large-scale production

Why Hot Runners Are Ideal

Ensures balanced filling across all cavities

Minimizes pressure and temperature variation

Improves part uniformity and yield rate

Multi-cavity molds are the most common and suitable application for hot runner systems.

2. High-Volume, Long-Running Production Molds

Common Industries

Packaging (caps, closures, containers)

Automotive components

Household appliances

Why Hot Runners Make Sense

Cold runners generate significant material waste at high volumes

Hot runners reduce per-part material cost

Shorter cycles increase machine productivity

The higher the production volume, the faster the ROI of a hot runner system.

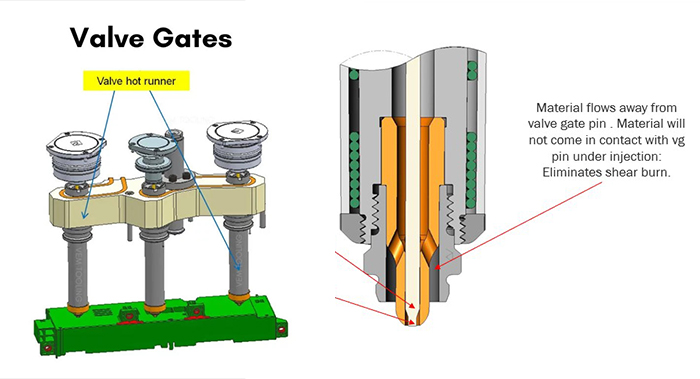

3. Molds with High Cosmetic or Surface Quality Requirements

Typical Products

Appliance housings

Consumer electronics

Medical or transparent parts

Why Hot Runners Are Preferred

Valve gate hot runners allow hidden or pinpoint gates

Reduced gate marks, stringing, and blush

Superior surface appearance

High-end cosmetic parts almost always rely on hot runner systems.

4. Molds Using Engineering or High-Value Plastics

Common Materials

PC, ABS, PA, PBT

Glass-filled nylon

Flame-retardant or medical-grade resins

Why Hot Runners Are Recommended

Engineering plastics are expensive—runner waste is costly

These materials require stable and precise temperature control

Hot runners reduce material degradation and scrap

The higher the material cost, the greater the benefit of hot runner systems.

5. Complex or Flow-Unbalanced Injection Molds

Typical Challenges

Uneven wall thickness

Long or asymmetric flow paths

Limited gate locations

Why Hot Runners Help

Multi-zone temperature control improves flow balance

Reduces short shots, warpage, and internal stress

Enhances process stability

Complex molds benefit greatly from the flexibility of hot runner temperature control.

6. Automated and Lights-Out Production Molds

Application Scenarios

Robotic part removal

Fully automated molding cells

24/7 continuous production

Why Hot Runners Are Ideal

No cold runners to remove or separate

Cleaner and more consistent automation

Less manual intervention

When a Hot Runner System May NOT Be Necessary

Hot runner systems are not always the best choice in the following cases:

Single-cavity or low-volume molds

Prototype or short product lifecycle projects

Extremely tight mold budgets

Parts with low cosmetic and material efficiency requirements

In such cases, cold runner molds may offer better cost-effectiveness.

How to Decide: Key Questions to Ask

Before choosing a hot runner system, ask:

Is the mold multi-cavity or high-volume?

Is the plastic material expensive or temperature-sensitive?

Are surface quality and consistency critical?

Is the mold intended for long-term production?

If most answers are yes, a hot runner system is likely the best solution.

Conclusion

Hot runner systems are not a universal requirement—but for multi-cavity, high-volume, high-quality, and automation-ready injection molds, they are often the optimal choice.

By eliminating runner waste, improving melt stability, and enabling precise temperature control, hot runner systems deliver long-term cost savings and superior product quality—making them a strategic investment rather than just a technical upgrade.