Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

The Role of Precision Temperature Control in Medical Device Molding with Hot Runner Temperature Controllers

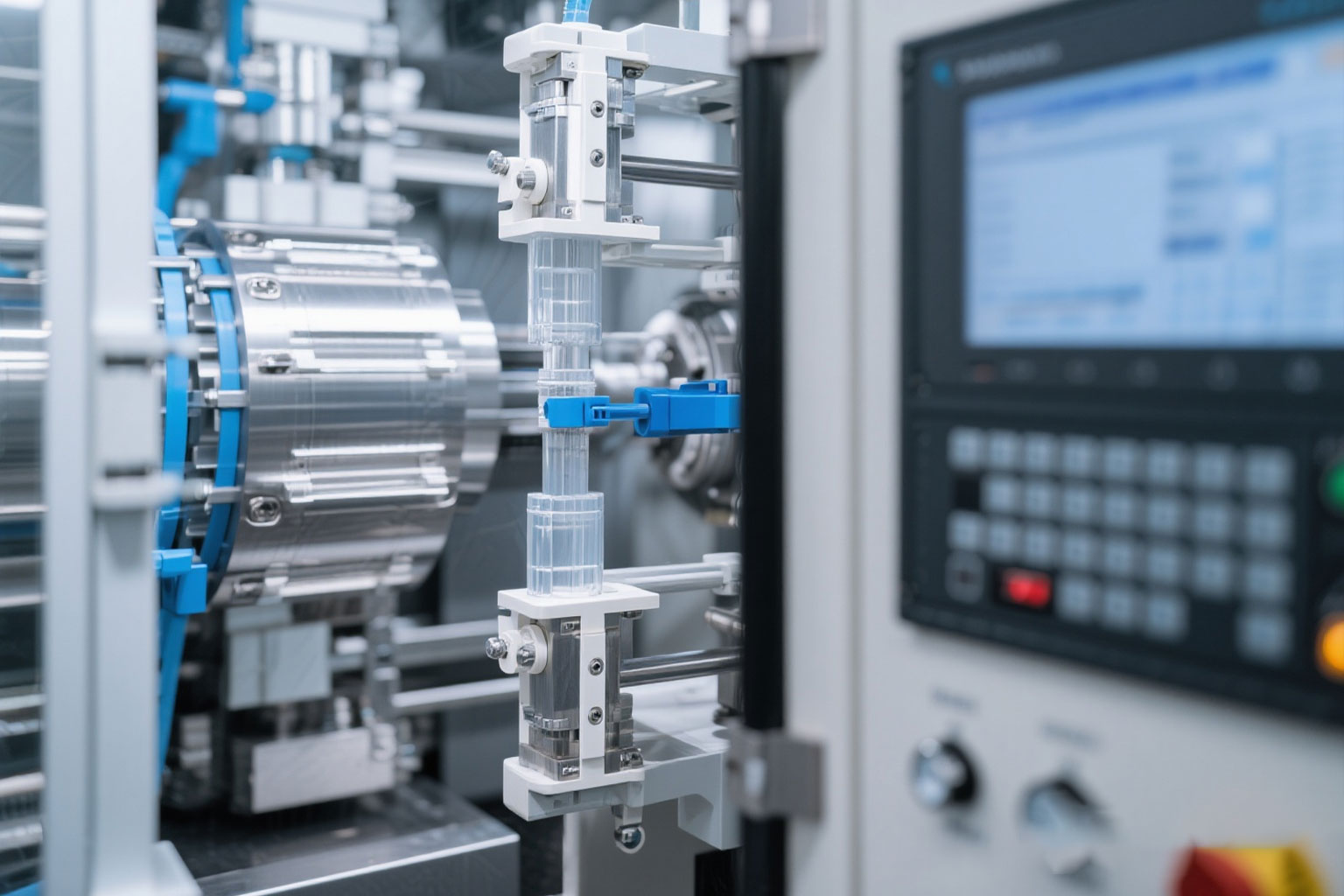

Injection molding is the foundation for producing high-quality medical device components such as syringes, catheters, and surgical tool handles. In this process, precise control over temperature is crucial. Even minor fluctuations can cause defects that compromise performance and fail strict FDA and ISO standards. This is where hot runner temperature controllers become indispensable for manufacturers.

In this blog, we’ll explore why precision temperature control is critical in medical device molding, the common problems caused by poor control, and how Topower’s advanced hot runner controllers help achieve perfect molding results.

Why Precision Temperature Control is Essential in Medical Device Injection Molding

In medical injection molding, polymers must maintain an exact temperature during the entire injection cycle. If the melt cools too quickly, parts will not fill completely, causing short shots. If it overheats, it can degrade the material. Hot runner temperature controllers ensure stable heating, which results in consistent part quality.

Uneven heating can lead to dimensional variations, surface defects, or warping—issues that are unacceptable in medical components like IV connectors or syringe barrels. For multi-cavity molds, precision temperature control keeps all cavities filling uniformly, avoiding part-to-part variation.

The Role of Hot Runner Temperature Controllers in Medical Device Manufacturing

Hot runner systems deliver molten polymer through heated manifolds and nozzles directly into the mold cavities. To maintain consistent melt flow, each zone needs independent temperature regulation. This is where hot runner controllers come in—they manage every zone with advanced PID algorithms, keeping temperature within ±0.1°C for maximum consistency.

Topower’s hot runner temperature controllers feature modular designs, user-friendly interfaces, and multi-zone capability (from 6 to 120 zones), making them ideal for complex medical device molds.

Common Problems from Poor Temperature Control in Medical Injection Molding

Without precise temperature control, manufacturers face:

Short shots – Incomplete filling due to premature cooling.

Flash – Excess polymer escaping the mold at high temperatures.

Warping and sink marks – Caused by uneven cooling or hot spots.

Color streaks and discoloration – Resulting from inconsistent melt temperatures.

Dimensional inconsistencies – Critical for medical device components that require tight tolerances.

These issues increase scrap rates and production costs, while also delaying time-to-market for critical medical products.

How Topower Hot Runner Temperature Controllers Improve Medical Device Molding

Topower’s hot runner controllers provide:

Ultra-precise accuracy (±0.1°C) – Keeps each mold zone at the exact set temperature.

Modular multi-zone support – Handles many cavities (whether you need 1 zone or 120). All models adapt to your moulding requirements.) with interchangeable modules.

Auto-tuning PID control – Automatically adjusts heater power for smooth startup and stable operation.

Diagnostics and Safety Alarms – Detects broken sensors or heater failures and alerts the operator (or shuts down that zone).

Data logging and connectivity – Records temperature histories for quality records, with USB/Ethernet connections for Industry 4.0 integration.

Waste and Cost Reduction – Advanced closed-loop control can cut plastic waste by 20–30%, saving on expensive medical-grade resins.

High power and safety – Each zone supports up to 3600W heating and includes built-in protections (e.g., thermocouple break alarms).

Reliable construction – Designed for cleanroom use and certified to global standards. Precise controllers help meet FDA/ISO cleanroom and validation standards, with built-in traceability for audits.

These features reduce material waste, eliminate defects, and ensure medical device manufacturers achieve zero-defect production goals.

Case Study: Syringe Component Manufacturing

A leading medical device manufacturer faced high scrap rates when molding syringe housings. The issue? Uneven temperature control caused short shots and warping. After implementing Topower’s multi-zone hot runner temperature controller, every cavity maintained perfect heat balance. Defect rates dropped by 90%, and the process achieved full compliance with regulatory standards.

Compliance and Traceability for Medical Device Standards

Regulatory frameworks like ISO 13485 and FDA guidelines demand strict process control and traceability. Topower’s hot runner controllers record temperature data and provide alarms for deviations, making validation (IQ/OQ/PQ) easier. This ensures medical molding processes meet all compliance requirements.

Why Equipment Manufacturers Should Choose Topower Controllers

Injection molding machine builders can gain a competitive advantage by integrating Topower hot runner controllers. These controllers deliver consistent performance, user-friendly operation, and reliable compliance features, making them a perfect fit for medical device manufacturing environments.

Topower’s Controller Series

Topower offers a range of controller models to match different mold sizes. Their TP series is a modular controller compatible with standard hot runner systems (like YUDO, DME, Husky) and typically covers 1–12 zones. The HY20 series adds a color touchscreen interface and supports up to 120 zones. All models use advanced PID control and thermocouple feedback to achieve precise regulation.

Conclusion: The Future of Precision in Medical Device Injection Molding

As medical devices become smaller and more complex, precision temperature control will play an even bigger role in ensuring quality and patient safety. Investing in advanced hot runner temperature controllers like those from Topower is the best way to guarantee defect-free production, compliance, and cost efficiency.

Call to Action

Looking for reliable hot runner temperature controllers for your medical device molding applications?

Visit Topower to explore our advanced solutions designed for precision, compliance, and efficiency.

Contact us today to discuss your project and find the right temperature control solution for your molding needs.