Overmolding Injection Molding: Process, Benefits, and Comparison with Insert Molding

IntroductionIn the competitive world of product design and manufacturing, engineers and procurement managers are constantly searching for ways to enhance functionality, improve ergonomics, and reduce ...

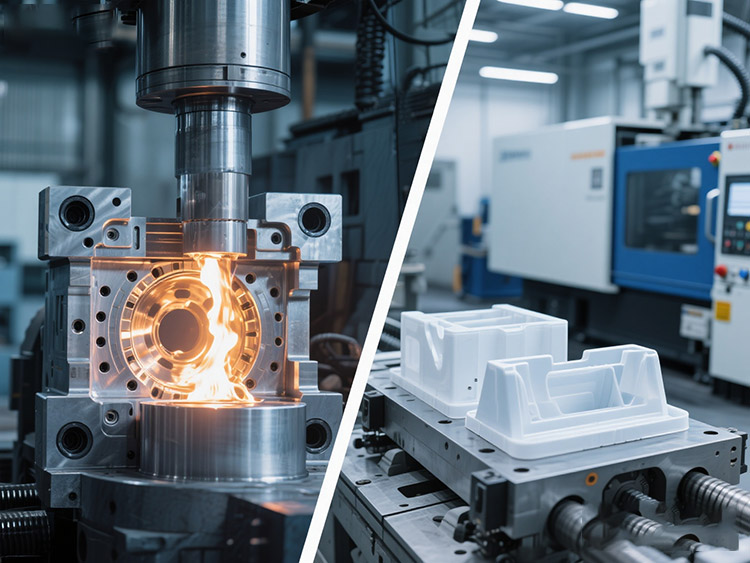

Die Casting vs Injection Molding: How to Choose the Right Molding Process for Your Product

When selecting a manufacturing route, the decision often comes down to Die Casting vs Injection Molding. Both are high-volume, repeatable processes, but they serve different materials, mechanical need...

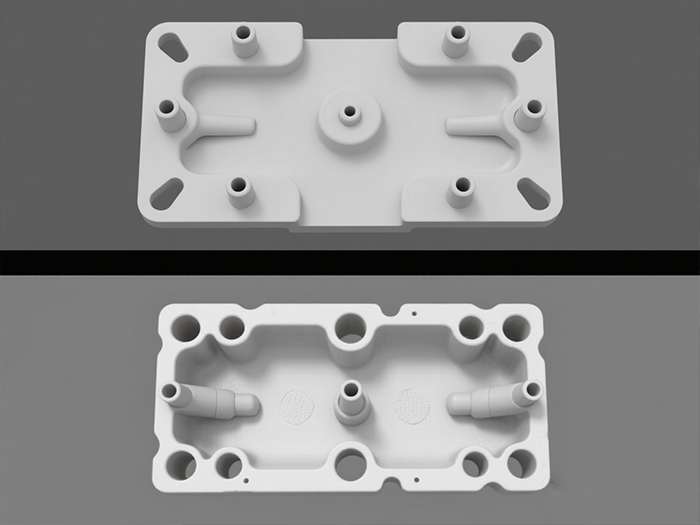

What Are The Types Of Injection Molding?

Injection molding types determine the right manufacturing path for a product — from standard injection molding for high-volume plastic housings to specialized micro injection molding ...

10 Key Parameters for Choosing a Hot Runner Temperature Controller

In the injection molding industry, hot runner temperature controller is essential to ensure stable mold performance and consistent product quality. As the demand for precision, appearance, and pe...

Common Challenges in PPO Injection Molding and How to Solve Them

IntroductionPolyphenylene Oxide (PPO) is a high-performance engineering thermoplastic widely used in automotive, electronics, and medical components due to its excellent dimensional stability, heat re...

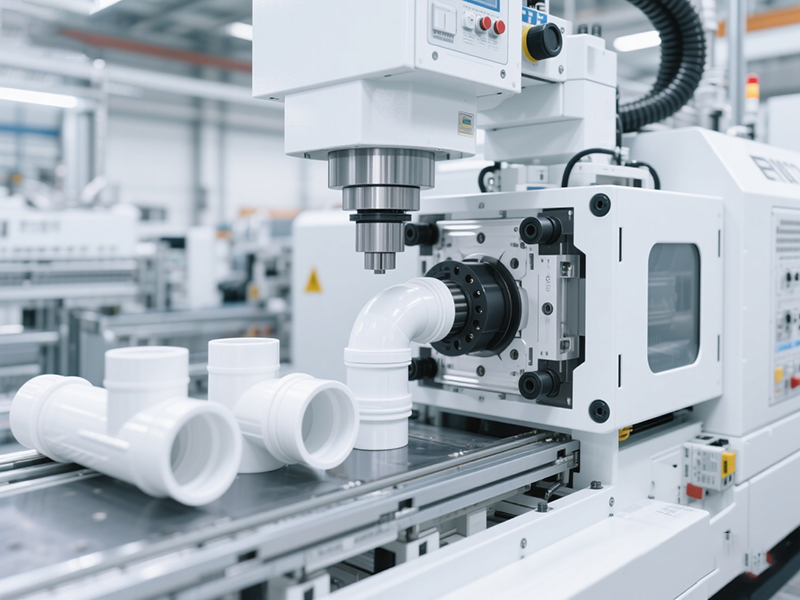

How to Optimize Mold Design for Efficient PVC Injection Molding

IntroductionPVC is a popular thermoplastic in injection molding thanks to its versatility and cost-effectiveness. However, it is also heat-sensitive and releases corrosive gases, making mold design a ...

PVC Injection Molding: A Complete Guide for Mold Manufacturers

IntroductionPolyvinyl Chloride (PVC) is one of the most widely used thermoplastics in the injection molding industry. From electrical components to medical devices and construction materials, PVC inje...