Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

PVC Injection Molding: A Complete Guide for Mold Manufacturers

Introduction

Polyvinyl Chloride (PVC) is one of the most widely used thermoplastics in the injection molding industry. From electrical components to medical devices and construction materials, PVC injection molding offers mold manufacturers a cost-effective and versatile solution. However, molding PVC requires precise temperature control, specialized mold design, and knowledge of potential processing challenges.

This guide provides mold makers with everything they need to know about PVC injection molding, including what it is, its advantages, applications, the molding process, defect prevention, and best practices.

What Is PVC Injection Molding?

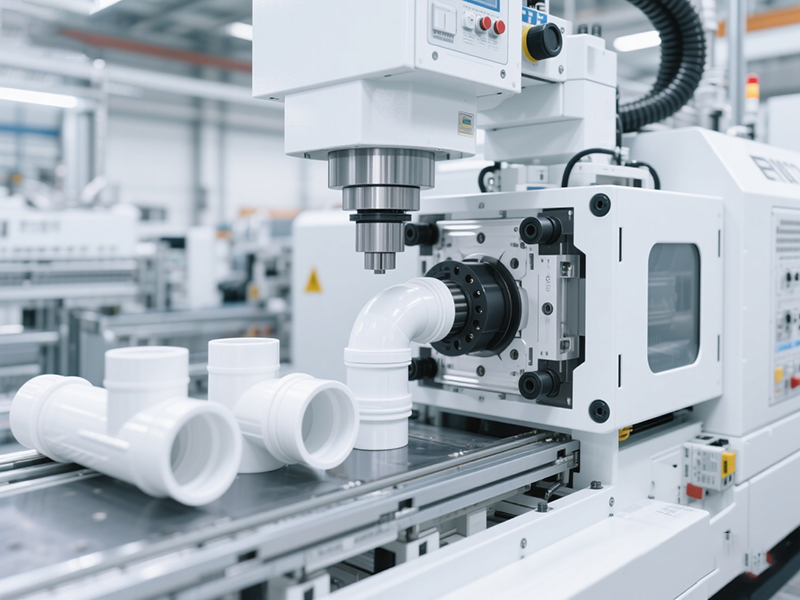

PVC injection molding is a manufacturing process where PVC resin is melted, injected into a mold cavity, and cooled to form solid parts. Unlike other plastics, PVC has unique characteristics such as high rigidity, chemical resistance, and flame retardancy.

There are two primary types of PVC used in injection molding:

Rigid PVC (uPVC): Commonly used in construction, pipes, fittings, and profiles.

Flexible PVC: Modified with plasticizers, used in medical tubing, seals, and gaskets.

For mold manufacturers, understanding these material differences is crucial for selecting the right process parameters and mold design.

Advantages of PVC Injection Molding

Mold manufacturers choose PVC injection molding for several key benefits:

Cost-Effectiveness: PVC resin is relatively inexpensive compared to many engineering plastics.

High Strength and Durability: Rigid PVC offers excellent mechanical properties for structural parts.

Chemical and Corrosion Resistance: Ideal for applications in plumbing, electrical, and chemical environments.

Flame Retardancy: PVC naturally resists combustion, making it suitable for electrical housings.

Design Flexibility: Compatible with complex mold designs and thin-walled parts.

For manufacturers seeking to maximize efficiency, precise temperature control systems, such as CNTOPower’s hot runner temperature controllers, enable the maintenance of consistent part quality and minimize production waste.

Applications of PVC Injection Molding

PVC injection molding is widely adopted in various industries. Some major applications include:

Construction: Pipes, window profiles, siding, and fittings.

Electrical & Electronics: Switches, sockets, cable insulation, and electrical housings.

Medical Industry: Tubing, connectors, blood bags, and housings for medical equipment.Automotive: Interior trims, seals, and under-the-hood components.

Consumer Goods: Toys, packaging, and household appliances.

Each application demands tight tolerance and dimensional accuracy, which is why many manufacturers integrate multi-zone hot runner controllers to stabilize PVC flow inside the mold.

PVC Injection Molding Process

The molding process for PVC is similar to other thermoplastics but requires additional care due to its thermal sensitivity.

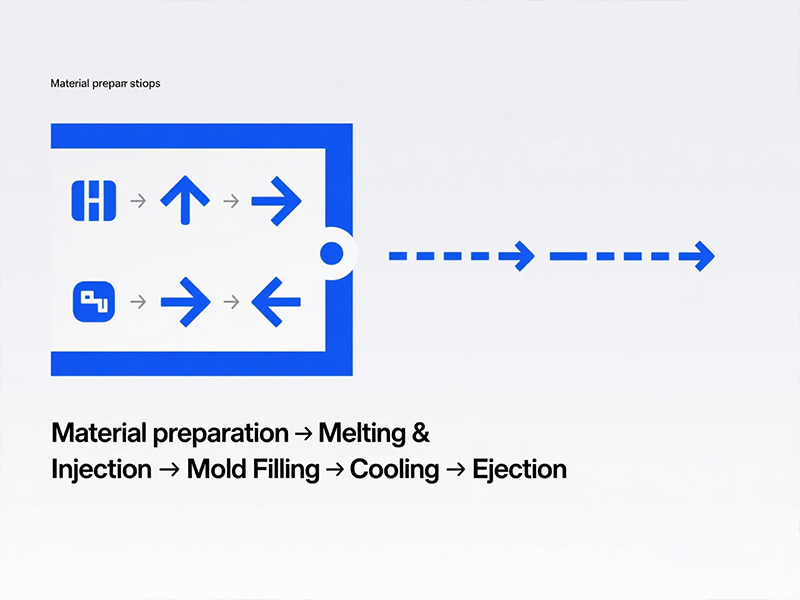

Key Steps in the Process:

Material Preparation

PVC resin must be properly dried to avoid moisture-related defects.

Melt temperature: 160–210°C for rigid PVC; lower for flexible PVC.

Precise temperature control is essential since overheating can degrade PVC.

Uniform flow is critical to avoid defects like burn marks or voids.

CNTOPower’s hot runner temperature control systems ensure stable cavity filling.

Longer cooling cycles are often required due to PVC’s lower thermal conductivity.

Melting and Injection

Mold Filling

Cooling and Ejection

Mold manufacturers must pay extra attention to venting and gating design to avoid decomposition and ensure high-quality parts.

Common Defects in PVC Injection Molding and Solutions

Despite its benefits, PVC molding is prone to certain issues:

Burn Marks or Discoloration → Caused by overheating; solution: better temperature control.

Voids or Bubbles → Due to trapped air or moisture; solution: proper drying and venting.

Warping → Uneven cooling; solution: uniform mold temperature and optimized cycle times.

Poor Weld Lines → Insufficient melt flow; solution: hot runner optimization.

Using advanced temperature controllers helps mold makers prevent these common defects, ensuring consistent product quality.

Mold Design Considerations for PVC Injection Molding

PVC has unique processing challenges that demand thoughtful mold design:

Corrosion-Resistant Steel: PVC releases hydrogen chloride when degraded, which can corrode molds.

Proper Venting: To release trapped gases and prevent burn marks.

Optimized Gate Design: Ensures balanced filling and reduces weld line formation.

Temperature Zones: Multi-zone hot runner systems improve flow and reduce stress.

Mold manufacturers who use Topower’s multi-zone hot runner controllers gain better control over PVC molding, improving efficiency and extending mold lifespan.

Future Trends in PVC Injection Molding

The PVC molding industry is evolving with technological innovations:

Smart Temperature Control Systems for real-time monitoring and predictive maintenance.

Sustainable PVC Alternatives with lower environmental impact.

Automation and AI Integration to improve cycle times and reduce human error.

Energy-Efficient Machines designed to optimize production costs.

For mold manufacturers, adopting these innovations means staying competitive in global markets.

Conclusion

PVC injection molding offers mold manufacturers versatility, durability, and cost efficiency across industries like construction, automotive, and healthcare. However, achieving high-quality results requires precise temperature control, optimized mold design, and defect prevention strategies.

At TOPower, we provide advanced hot runner temperature controllers designed to help mold makers achieve consistent PVC molding performance. Our solutions reduce defects, improve cycle efficiency, and extend mold life — making them the ideal choice for manufacturers working with PVC.

Call to Action

Looking to improve your PVC injection molding process?

Contact Topower today to learn how our hot runner temperature controllers can help you achieve greater precision, efficiency, and product quality.