Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

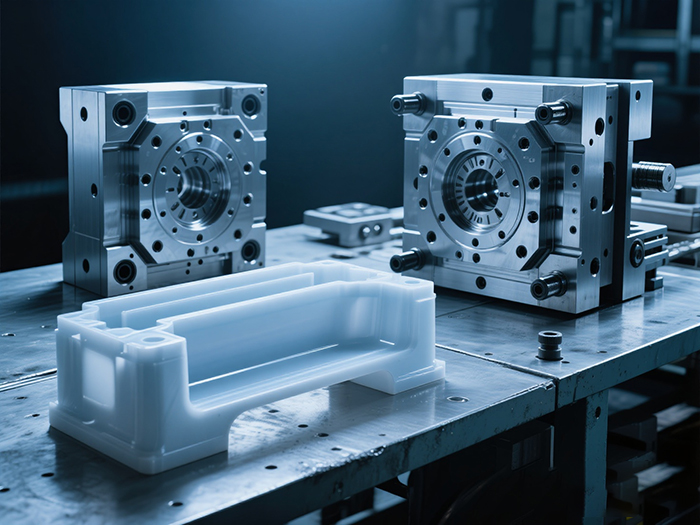

How to Optimize Mold Design for Efficient PVC Injection Molding

Introduction

PVC is a popular thermoplastic in injection molding thanks to its versatility and cost-effectiveness. However, it is also heat-sensitive and releases corrosive gases, making mold design a critical factor for success. A well-optimized mold reduces defects, extends mold life, and improves production efficiency. This article explores the essential principles of PVC mold design and shows how advanced temperature control can further enhance results.

Why PVC Needs Special Mold Design

PVC behaves differently from most plastics:

Thermal sensitivity → risk of degradation if overheated.

Gas release → requires corrosion-resistant steels and effective venting.

High shrinkage → demands uniform wall thickness and careful cooling.

Rigid structure → needs proper draft angles for smooth ejection.

These characteristics make design optimization essential for mold manufacturers.

Key Principles for Optimizing PVC Mold Design

Mold Materials

PVC’s corrosive byproducts can quickly damage ordinary steel. Stainless steel (420SS) or plated tool steels are commonly used for their resistance to corrosion and wear. For areas that are difficult to cool, beryllium copper inserts help improve heat transfer and reduce cycle time.

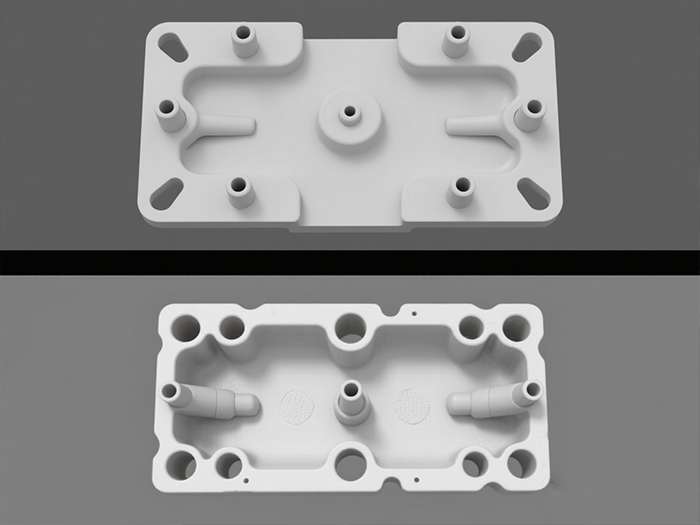

Gate Design

PVC’s higher viscosity means it needs larger or multiple gates to ensure smooth filling. Fan gates are effective for reducing warpage and maintaining flatness. Gates should be positioned in thicker sections, away from cosmetic surfaces, and designed to minimize shear and stress.

Cooling System

Uneven cooling is one of the main causes of warpage and shrinkage in PVC parts. Cooling channels should be well distributed and independent for each mold half. Using conductive inserts in hot zones improves temperature balance. The goal is to maintain consistent mold temperature, preventing differential shrinkage and improving cycle efficiency.

Venting

Without proper venting, PVC is prone to burn marks, voids, and short shots. Vent depths are typically 0.0006–0.0010″ for rigid PVC. Vents should be placed opposite gates and near ejector pins to allow trapped air to escape without weakening the part.

Surface Finish

The mold’s surface directly impacts the part’s appearance and release. Polished surfaces are ideal for transparent or glossy parts, while textured finishes help hide flow lines or minor defects. Protective coatings or plating are recommended to resist corrosion from PVC gases.

Ejection System

Ejection must be smooth to prevent cracking or marks. Use draft angles of 2° or more, and large ejector pins or sleeves to distribute force. Stripper plates or air ejection are useful for thin-wall parts or complex geometries where pins alone may cause damage.

Common Defects from Poor Mold Design

Burn Marks and Discoloration

Problem

Burn marks appear as dark streaks or blackened areas on the molded PVC parts. They are typically caused by overheating of the material during injection.

Root Causes

Excessive melt temperature

Poor venting in the mold cavity

High injection speed causes frictional heating

Solutions

Lower melt and barrel temperature to prevent thermal degradation

Improve mold venting to release trapped gases

Optimize injection speed and screw rotation

Use multi-zone hot runner controllers (such as Topwer systems) to maintain precise temperature across all mold cavities

By adopting advanced temperature control, manufacturers can significantly reduce the risk of PVC degradation and burnt surfaces.

Voids and Bubbles

Problem

Voids or bubbles form when air, moisture, or gases get trapped in the molten PVC, leaving cavities inside the molded part.

Root Causes

Inadequate drying of PVC resin

Poor venting or trapped gases in the mold

Inconsistent temperature during filling

Solutions

Pre-dry PVC resin to remove moisture

Design molds with better venting channels

Reduce injection pressure to allow gases to escape

Employ precise temperature controllers to maintain uniform flow and reduce trapped air

Warpage and Deformation

Problem

Warpage occurs when molded PVC parts twist, bend, or deform after ejection, making them dimensionally inaccurate.

Root Causes

Uneven cooling across the mold cavity

Inconsistent wall thickness in part design

Residual stress due to poor flow control

Solutions

Design molds with uniform wall thickness

Balance the cooling system to ensure consistent temperature

Optimize gate design for even filling

Use multi-zone hot runner temperature control to prevent uneven flow and reduce internal stress

Topower controllers provide real-time monitoring and stable heating, helping mold manufacturers reduce warpage rates significantly.

Weld Lines

Problem

Weld lines are visible lines or weak spots where two melt fronts meet but fail to fuse properly.

Root Causes

Low melt temperature

Poor gate positioning

Inadequate injection pressure

Solutions

Increase melt and mold temperature slightly for better material fusion

Redesign gate and runner system to optimize flow paths

Use hot runner systems with independent temperature zones to maintain consistent melt flow across cavities

Short Shots (Incomplete Filling)

Problem

A short shot occurs when the molten PVC fails to completely fill the mold cavity, leaving incomplete parts.

Root Causes

Insufficient injection pressure or speed

Blocked gate or inadequate runner design

Low melt temperature causing high viscosity

Solutions

Increase injection pressure and screw speed

Redesign runners and gates for better flow

Use advanced temperature control systems to keep PVC at an optimal viscosity

Surface Defects: Roughness and Flow Marks

Problem

Surface defects reduce the aesthetic and functional quality of PVC molded products, often appearing as rough textures, streaks, or flow marks.

Root Causes

Uneven melt temperature

Poor mold polishing or finish

Inconsistent injection speed

Solutions

Improve mold surface finish

Ensure consistent injection speed and pressure

Stabilize melt temperature with high-precision hot runner controllers

Role of Temperature Control

Even the best-designed mold cannot perform without precise temperature management. Multi-zone hot runner controllers stabilize cavity temperatures, preventing degradation, cold spots, and flow imbalance.

Topwer’s HY20 series hot runner controllers offer ±1% accuracy and up to 120 zones, ensuring consistent melt flow and fewer defects. For mold manufacturers, this means shorter cycles, higher part quality, and reduced scrap.

Conclusion

Optimizing mold design for PVC injection molding ensures fewer defects, improved efficiency, and longer mold life. Combined with advanced temperature control systems, it creates a reliable, profitable production process.

Ready to optimize your PVC molds? Visit Topower’s hot runner controller page and fill out our consultation form to get tailored solutions from our experts.