In modern injection molding, precision is not optional—it is fundamental. At the center of th...

What Is a Sequential Timer Controller for Injection Molding and Why You Need It

What Is a Sequential Timer Controller?

A Sequential Timer Controller is a specialized control device used in hot runner injection molding systems with valve gates. Its primary function is to precisely control the opening and closing timing of each valve gate nozzle, allowing molten plastic to flow into mold cavities in a programmed sequence.

Unlike conventional systems, where all gates open simultaneously, a sequential timer controller activates each channel (or zone) after an individually programmed delay time. This staged filling process balances the melt front in multi-drop and multi-cavity molds, resulting in uniform flow distribution and improved surface quality.

In practical operation, the controller receives a trigger signal from the injection molding machine—typically a 24V DC or AC signal at the start of injection. Based on the preset timing logic, it then sequentially energizes each valve gate solenoid. By precisely managing flow timing, sequential timer controllers play a crucial role in complex or large hot runner molds, where flow balance has a direct impact on part quality and production stability.

Why Timing Control Matters in Injection Molding

Precise valve gate timing has a significant impact on molded part quality. When multiple gates open simultaneously, melt fronts collide, often creating weld lines, flow marks, and internal stress. Uneven cavity filling may also lead to warpage, sink marks, and excessive clamp force requirements.

Sequential gating enables gradual and controlled cavity filling, effectively eliminating many of these issues.

Key Benefits of Sequential Timer Control

Elimination of weld lines and surface defects

Sequential filling prevents melt front collisions, improving cosmetic appearance and structural integrity.

Balanced cavity filling

Staggered gate opening equalizes flow in multi-cavity molds, reducing warpage and sink marks.

Reduced clamp force and mold stress

By avoiding simultaneous gate opening, injection pressure is distributed in stages, lowering peak pressure and extending mold life.

Fewer short shots and flashes

Individual timing control allows fine adjustment of material flow per gate, minimizing incomplete filling and overpacking.

Controlled weld line positioning

For appearance-critical parts (such as automotive interior or exterior panels), engineers can relocate weld lines to less visible areas.

Collectively, these advantages lead to higher yield rates, reduced scrap, and more consistent production quality, while also improving long-term mold reliability.

Typical Features and Configurations

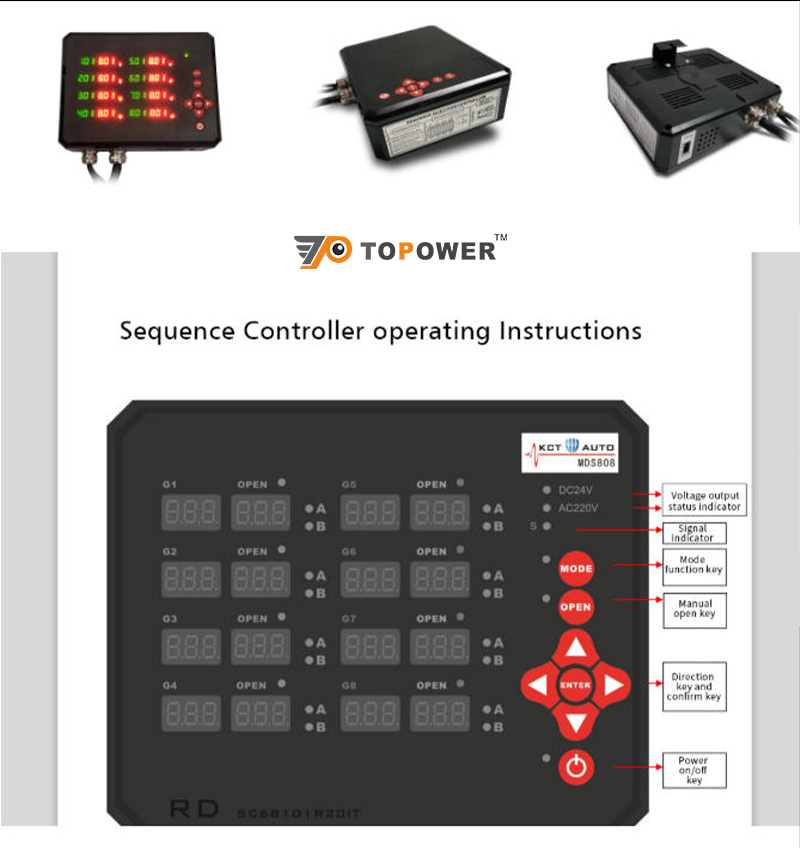

Modern Hot Runner Sequential Timer Controllers share several core features designed for industrial injection molding environments:

Multi-Zone Control

Controllers are available in multiple channel configurations—commonly 4, 8, and 16 zones—to match the number of valve gates in the mold. Some systems support even higher channel counts for large-scale molds.

Programmable Timing

Each channel allows independent adjustment of:

Delay time (after receiving the injection signal)

Gate open time

Timing resolution is typically as precise as 0.01 seconds, enabling highly accurate flow control.

Power Supply and Input Signals

Input power: Single-phase AC100–240V, 50/60Hz (often supporting a wider range such as 85–265V)

Input signal: 24V DC, 110V AC, 220V AC, or dry contact from the injection molding machine

The input signal determines when the timing sequence begins.

Valve Gate Outputs

Each channel provides an independent output, commonly selectable as:

24V DC

110V AC

220V AC

These outputs directly drive valve gate solenoids without additional interface modules.

Hydraulic and Pneumatic Compatibility

All-in-one designs support both:

Pneumatic valve gate systems

Hydraulic valve gate systems

Some models include high-current 24V DC outputs specifically designed for hydraulic valve actuation.

Operating Modes

Automatic mode for production

Manual mode for testing and maintenance

All settings are stored in non-volatile memory to ensure repeatability after power loss.

How a Sequential Timer Controller Works with the Injection Molding Machine

The controller operates in synchronization with the injection molding machine cycle:

Injection signal received

The molding machine sends a trigger signal (typically 24V DC) at the end of the injection stroke or at the start of holding pressure.

Initial delay period

All valve gates remain closed during their individually programmed delay times.

Sequential gate opening

When Channel 1’s delay expires, the controller energizes its output (24V DC or AC voltage) to open the first valve gate.

Subsequent gates open sequentially after their respective delays.

Each gate remains open for its programmed duration.

Cycle completion

Once all gates have opened (and closed if programmed), the injection cycle finishes and the machine proceeds to holding and cooling.

This timing logic is managed entirely by the controller’s internal processor, ensuring precise synchronization with the molding cycle.

Electrical Specifications and Industrial Design

Sequential timer controllers are engineered for demanding industrial conditions:

Input voltage: 85–265V AC, 50/60Hz

Output current: Typically 1–3A per channel

Standard valve control voltage: 24V DC

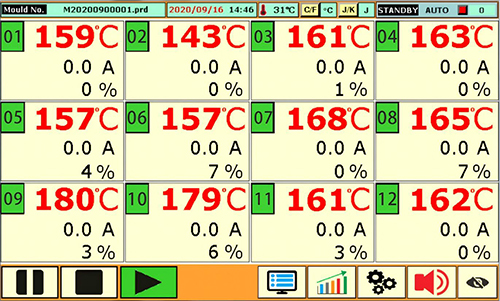

The controllers are housed in rugged metal enclosures suitable for panel or rack mounting. Interfaces may include LED or LCDs, push buttons, or touchscreens. Most units comply with CE safety standards and are designed for stable operation in 0–50°C industrial environments.

Advantages of an All-in-One Sequential Timer Controller

An integrated sequential timer controller simplifies system design and operation:

Supports both hydraulic and pneumatic valve gates

One controller can be used across different mold types without additional hardware.Wide power input range

AC100–240V compatibility allows global deployment.Compact system architecture

8- or 16-channel units reduce panel space and wiring complexity.User-friendly operation

Clear displays and intuitive programming improve setup efficiency.Industrial reliability

Noise filtering, surge protection, and CE compliance ensure long-term stability.

Optimized Sequential Control for Modern Hot Runner Molds

For injection molders seeking stable, repeatable, and high-precision valve gate control, a Sequential Timer Controller is no longer optional—it is essential.

Our Hot Runner Sequential Timer Controller is designed specifically for modern injection molding environments. It supports 8-channel and 16-channel configurations, combining hydraulic and pneumatic valve gate control in a single unit. Powered by single-phase AC100–240V (50–60Hz) and providing DC 24V output for spiral tube needle valves, it integrates seamlessly with most injection molding machines worldwide.

Once the controller receives the injection signal, each valve gate is activated precisely after its programmed delay, with fully adjustable open time. This allows mold engineers to optimize flow balance, reduce weld lines, minimize internal stress, and achieve superior part quality—especially in multi-cavity, large, or appearance-critical molds.

Whether you are developing new hot runner systems or upgrading existing molds, our Sequential Timer Controller for Injection Molding delivers a cost-effective, reliable, and engineering-proven solution for diverse production requirements.

Learn more or request technical specifications:

https://www.cntopower.com/TimeSequentialController/sequential-timer.html