Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

The Evolution of Hot Runner Temperature Controllers: From Manual to Smart Systems

Hot runner temperature controllers are essential in injection molding systems, ensuring stable melt flow, consistent part quality, and reduced defects. Over time, these controllers have evolved from basic manual units into smart hot runner controllers with touchscreen interfaces, multi-zone precision, and Industry 4.0 connectivity. This transformation reflects the rising demand for accuracy, energy efficiency, and digital integration in plastic manufacturing.

From Manual Controllers to Early Analog Systems

In the early days, manual hot runner controllers were simple analog devices. Operators adjusted dials or switches to regulate heaters, but accuracy was poor, often fluctuating several degrees Celsius. This lack of precision led to material degradation, flow imbalance, and higher scrap rates. Analog controllers operated as standalone units with no integration to molding machines, slowing production efficiency.

The Shift to Digital and PID Hot Runner Controllers

By the 1990s, digital hot runner controllers equipped with PID (Proportional-Integral-Derivative) algorithms revolutionized injection molding. These systems offered ±1 °C accuracy, stabilizing temperature more reliably and reducing defects. Multi-zone capabilities enabled independent heater management, while digital displays and programmable profiles made operation more user-friendly. Digital PID hot runner controllers quickly became the backbone of modern molding processes.

Networked and Multi-Zone Hot Runner Controllers

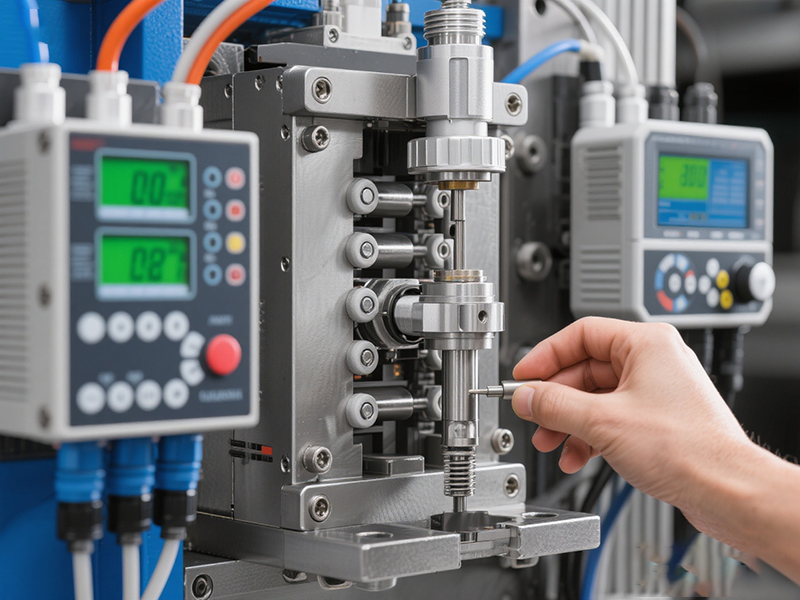

As automation spread, multi-zone hot runner controllers began integrating with molding machines. Ethernet and OPC-UA communication enabled seamless connection with PLCs and MES systems. Recipe storage, remote monitoring, and real-time data logging allowed faster setup and improved process reliability. Touchscreen HMIs replaced buttons and LED displays, making temperature management intuitive for operators.

Smart Hot Runner Controllers and Industry 4.0

Today, manufacturers rely on smart hot runner controllers that combine IoT, AI, and predictive maintenance. Key features include:

Real-time diagnostics – monitoring heater load, thermocouple performance, and circuit health.

Predictive maintenance – identifying heater wear before failures occur.

AI auto-tuning – adjusting PID parameters in real time for optimized thermal balance.

Cloud connectivity – remote monitoring and data-driven decision-making.

These Industry 4.0 hot runner temperature controllers not only ensure tighter temperature control but also reduce downtime, improve energy efficiency, and support sustainable production.

Topower Touchscreen Hot Runner Controller

One of the leading solutions in this new generation is the Topower PLC Touchscreen Hot Runner Controller.

User-Friendly Touchscreen Interface – intuitive control with real-time monitoring.

High-Precision PID Control – ensures stable temperature with minimal fluctuation.

Multi-Zone Management – handles complex molds with consistent accuracy.

Industry 4.0 Ready – supports Ethernet communication and factory integration.

Compact Design – space-saving while delivering high performance.

This advanced touchscreen hot runner temperature controller is designed for engineers who demand both precision and connectivity, making it a smart choice for automotive, packaging, and medical molding applications.

Comparative Overview of Hot Runner Controller Generations

| Generation | Accuracy & Stability | Ease of Use | Integration |

| Manual / Analog | ± several °C; low precision | Knobs and dials; manual setup | Standalone; no machine connection |

| Digital PID | ±1 °C; stable and reliable | Digital display; programmable profiles | Basic connectivity (RS-232/485) |

| Multi-Zone / Networked | Sub-degree stability | Touchscreen HMIs; recipe storage | Ethernet, OPC-UA, PLC integration |

| Smart / Industry 4.0 | Adaptive, predictive (~0.1 °C) | Web/mobile interfaces; AI-assisted | Cloud, IoT, predictive maintenance |

Conclusion

The evolution of hot runner temperature controllers highlights the shift from manual operation to smart, connected systems. Each stage—from analog knobs to touchscreen PLC controllers—has improved precision, usability, and efficiency. For today’s engineers, adopting a smart hot runner controller means lower scrap, faster setup, and long-term cost savings.

Ready to upgrade? Explore the Topower Touchscreen Hot Runner Controller and discover how advanced PID control and Industry 4.0 connectivity can optimize your injection molding process.