In modern injection molding, precision is not optional—it is fundamental. At the center of th...

Hot runner controller series product introduction

Topower TP series hot runner temperature controller is international size module which compatible with YUDO, DME, HUSKY, etc., temperature control system. It usually use for 1-12 zones/cavities mould.

Key Features and Materials

A hot runner temperature controller is equipped with advanced features such as PID (Proportional-Integral-Derivative) control. This feature ensures precise temperature adjustments, crucial for maintaining optimal performance in injection molding processes. These controllers are constructed from robust materials designed to withstand the rigors of industrial environments, ensuring longevity and reliability.

Models and Specifications

TP01 1 Zone (Cavity) International Modular Hot Runner Temperature Controller

TP01 2 ZONE (Cavity) International Modular Hot Runner Temperature Controller

TP01 4 ZONE (Cavity) International Modular Hot Runner Temperature Controller

TP01 6 ZONE (Cavity) International Modular Hot Runner Temperature Controller

TP01 8 ZONE (Cavity) International Modular Hot Runner Temperature Controller

TP01 12 ZONE (Cavity) International Modular Hot Runner Temperature Controller

For larger applications, the HY20 series offers:

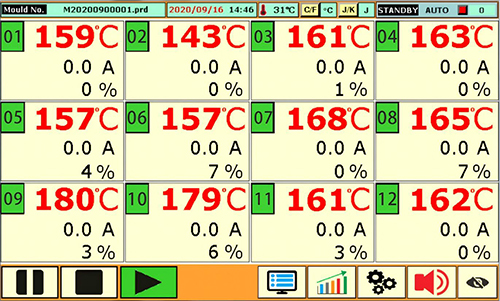

HY20 12 ZONE (Cavity) Touch screen Hot Runner Temperature Controller

HY20 24 ZONE (Cavity) Touch screen Hot Runner Temperature Controller

HY20 36 ZONE (Cavity) Touch screen Hot Runner Temperature Controller

HY20 48 ZONE (Cavity) Touch screen Hot Runner Temperature Controller

HY20 60 ZONE (Cavity) Touch screen Hot Runner Temperature Controller

These models cater to various industrial needs, providing flexibility and advanced control for different mold sizes and complexities.

Understanding Types and Applications

The versatility of hot runner temperature controllers extends beyond mere zone control. These devices are integral in producing a wide range of products across various industries. From crafting intricate medical components to manufacturing robust automotive parts, hot runner controllers ensure precision and efficiency.

Types of Controllers

Modular Temperature Controllers: Ideal for systems requiring scalability. They offer flexibility and adaptability, making them perfect for evolving production needs.

Mainframe Temperature Controllers: Suited for centralized control, these controllers manage larger, more complex systems, ensuring consistent performance across all zones.

The TP and HY series controllers cater to different needs, providing options for both simple and complex applications. Whether you need a basic modular setup or a sophisticated touch screen interface, these controllers deliver reliable and efficient temperature management tailored to specific production requirements.

Key Factors in Selecting the Right Temperature Controller for Hot Runners

When selecting a temperature controller for hot runner systems, several critical factors must be considered to optimize efficiency and ensure high-quality output.

Type of Plastic Used

Different plastics have varying thermal properties. It's crucial to choose a controller that can precisely regulate temperatures tailored to the specific plastic resin you are using.

Mold Design Complexity

The complexity of your mold design is another vital consideration. Intricate designs may require more advanced controllers with enhanced features for precise temperature management.

Molding Process Requirements

Understand the specific needs of your molding process. Whether it's a fast production cycle or a need for high precision, your controller should meet these operational demands to maintain process consistency.

Energy Efficiency

Opt for controllers with energy-efficient capabilities. This not only lowers operational costs but also enhances the sustainability of your manufacturing processes.

Ease of Use and Integration

Ensure the temperature controller integrates smoothly with your existing systems. Ease of use can significantly reduce setup times and potential errors during operation.

Reliability and Support

Choose a controller from a reputable manufacturer known for reliability and customer support. This ensures you have assistance whenever issues arise and that the equipment is built to last.

Focusing on these aspects will help you choose a temperature controller that enhances efficiency, supports your specific production needs, and contributes to the overall success of your injection molding operation.

The accuracy and stability of temperature control are critical to the performance of hot runner systems in injection molding. Below is a detailed analysis of the key factors influencing the performance of hot runner temperature controllers:

1. Temperature Measurement

The accuracy of temperature measurement serves as the foundation of the control system and depends on several factors:

Sampling Cycle: A faster sampling cycle captures real-time temperature changes, but an overly short cycle may introduce noise interference.

Data Filtering: Filtering algorithms (e.g., averaging or Kalman filtering) help reduce noise and ensure stable temperature readings.

emperature Compensation in Measurement Circuits: Compensates for errors caused by environmental temperature fluctuations, improving measurement precision.

2. PID Control

PID (Proportional-Integral-Derivative) control adjusts the output current to maintain the system near the setpoint, with the following parameters:

Proportional Band (P): Affects the response speed and error magnitude.

Integral Time (I): Corrects long-term errors and prevents cumulative deviation between the setpoint and actual value.

Derivative Time (D): Predicts temperature changes to suppress overshooting and oscillations.

PID control is suitable for most scenarios, especially when low noise and stable temperature control are required.

3. PIDD Control

PIDD (Proportional-Integral-Derivative + Phase Angle Control) builds upon PID by adding phase angle control to the output current:

Proportional Band (P), Integral Time (I), and Derivative Time (D) remain critical.

Phase Angle Control: Precisely adjusts the phase angle of current conduction, enhancing responsiveness and control accuracy.

PIDD mode is ideal for applications requiring high precision and fast response, but it demands more advanced hardware support.

4. Auto-Tuning

Auto-tuning enhances the intelligence of the temperature controller, particularly in environments with significant temperature fluctuations:

Capacitance and Thermal Constant Analysis: By analyzing the heater and mold’s thermal characteristics, the system automatically selects the optimal control parameters.

Latent Heat and Heat Dissipation Analysis: Regardless of environmental changes, auto-tuning ensures the stability of the hot runner system's temperature.

5. Output Modes

The output mode of the controller significantly affects temperature control performance and electrical noise:

SSR Mode (Solid-State Relay, PIDD):

Advantages: Offers precise temperature control.

Disadvantages: Generates significant electrical noise, potentially interfering with sensitive equipment.

PWM Mode (Pulse Width Modulation, PID):

Advantages: Produces minimal current noise, ideal for noise-sensitive environments.

Disadvantages: Slightly less effective in achieving high-precision temperature control compared to SSR mode.

In practical applications, SSR mode is preferred for high-precision and dynamic response requirements, while PWM mode suits production environments sensitive to noise.

What Advantages Does Precision Temperature Control Offer in Hot Runner Systems?

Precision temperature control in hot runner systems delivers a host of remarkable benefits essential for modern manufacturing. Here's how it can transform your production line:

Enhanced Material Flow: By maintaining optimal temperatures, precision control ensures that the plastic flows smoothly through the mold. This minimizes the risk of clogging and allows for consistent filling, critical for producing high-quality parts.

Reduced Waste: Accurate temperature management significantly reduces waste by minimizing defects and rejected parts. Consistent processing conditions help preserve material integrity, reducing the need for rework and scrap.

Improved Part Quality: The precise regulation of temperature directly contributes to the production of superior parts. It helps in maintaining uniformity in part dimensions and structural integrity, which is crucial in industries demanding high precision.

Ease of Monitoring and Adjustments: Modern digital temperature controllers simplify the monitoring and adjusting process. This ease of use is crucial for maintaining process efficiency, allowing operators to quickly respond to changes and ensure consistent operation.

Implementing a precision temperature control system in your hot runner setup can offer tangible improvements in efficiency and product quality, driving better results across your production line.

Conclusion

Hot runner temperature controllers are indispensable in ensuring efficient and high-quality injection molding processes. Understanding their features, working principles, and selection criteria can significantly improve production outcomes. For tailored solutions, consult an experienced hot runner controller manufacturer to optimize your system for precision and reliability.

Would you like help identifying the best manufacturers or specific product recommendations?

As a professional manufacturer of hot runner temperature controllers, Topower provides customers with complete hot runner systems and temperature control boxes. Topower offers both single-point and multi-point temperature control boxes, and we can customize temperature control products with various zones based on customer requirements, ensuring high-quality performance.