Contents1. Why cold runners drive waste in medical molding2. Eliminating Cold Runner Waste with hot ...

Market Prospects of Hot Runner Temperature Controllers in the Food and Beverage Industry

Hot Runner Temperature Controller Market size was valued at USD 750 million in 2022 and is anticipated to register a CAGR of over 3.6% between 2023 and 2032. Manufacturers are increasingly looking for customizable solutions to suit specific molding requirements.

Overall, hot runner temperature controllers hold significant growth potential in the food and beverage industry. As the sector continues to evolve and technology advances, these controllers play a crucial role in improving production efficiency, product quality, and reducing energy consumption.

1. Applications and Advantages

Temperature Stability

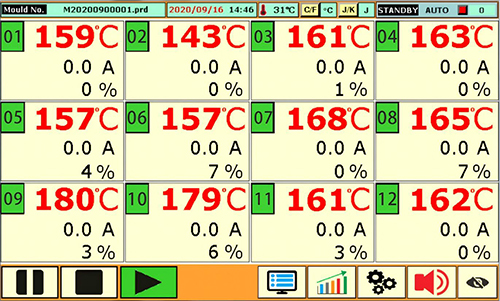

Hot runner temperature controllers can precisely regulate the temperature of hot runner systems, ensuring that plastic remains in a stable molten state during the injection molding process. This prevents defects caused by temperature fluctuations, such as shrinkage and warping.

Enhanced Production Efficiency

Through precise temperature control, hot runner systems can shorten cooling times in the molding cycle, boosting production efficiency. Moreover, stable temperature management minimizes material waste, reducing production costs.

Improved Product Quality

Accurate temperature control ensures dimensional stability and surface quality of finished products, reducing defect rates and enhancing overall product quality. This is especially critical for high-precision applications, such as food packaging.

Energy Efficiency

By avoiding overheating and energy waste through intelligent control, hot runner temperature controllers achieve energy savings and lower operational costs for businesses.

Easy Maintenance

Modern hot runner temperature controllers are typically equipped with intelligent monitoring and alarm features, facilitating maintenance and troubleshooting to ensure continuous and stable production.

2. Market Drivers

Growing Demand for Packaging

The food and beverage industry increasingly demands high-quality packaging, especially as consumer expectations for convenience, aesthetics, and functionality rise. Hot runner systems enhance the molding quality and production efficiency of packaging materials.

Sustainability Initiatives

The promotion of sustainable packaging has driven more companies to adopt plastic reduction technologies. Hot runner systems help minimize material waste and facilitate the use of biodegradable materials.

Automation and Smart Manufacturing

As the food and beverage sector moves toward automation and smart manufacturing, hot runner temperature controllers offer precise temperature control, reducing defect rates and improving production efficiency, aligning with the industry's automation goals.

Diverse and Customized Packaging Trends

The market's demand for innovative packaging designs, such as containers with unique shapes or structures, is increasing. Hot runner technology meets these needs while maintaining consistent quality.

3. Challenges and Solutions

Cost Considerations

High-performance hot runner temperature controllers involve significant initial investments but offer long-term savings by reducing material waste and improving production efficiency.

Compatibility with New Materials

Food-grade plastics and biodegradable materials require more stringent temperature control. Developing higher-precision, more stable controllers will be essential to accommodate these new materials in the future.

4. Future Trends

Smart Development

Integration with IoT and artificial intelligence technologies enables remote monitoring and predictive maintenance, further reducing downtime and maintenance costs.

Elevated Industry Standards

With stricter food safety and environmental regulations, the design of hot runner temperature controllers will need to meet higher hygiene and environmental requirements, such as dustproof, waterproof, and antibacterial designs.

Regional Market Growth

Emerging markets in Asia and Africa present growing consumer demands, bringing more packaging needs to the food and beverage industry. Hot runner systems are expected to capture significant market share in these regions.

5. Conclusion

In summary, the demand for hot runner temperature controllers in the food and beverage industry will continue to grow alongside the expansion of the packaging market and technological advancements. Market participants must proactively address challenges related to cost, technology, and regulations to seize this opportunity.