Streamlining Manufacturing: The Impact of Hot Runner Systems on Cost and Sustainability

2024-12-26

In the pursuit of enhanced efficiency and cost optimization, the injection molding industry has embraced technological advancements, with hot runner systems standing out as a groundbreaking innovation. Renowned for their ability to boost productivity, minimize material waste, and elevate product quality, hot runner technology has revolutionized manufacturing processes, making it a beacon of industrial progress.

The Fundamentals of Hot Runner Technology

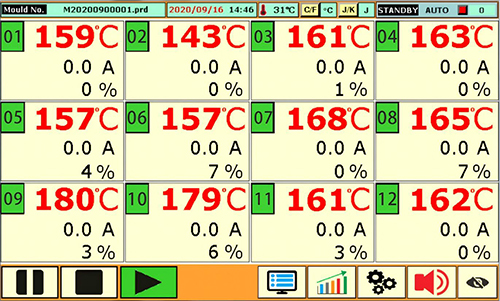

Hot runner systems integrate advanced heating mechanisms within molds to maintain molten plastic in the flow channels and gates, enabling precise temperature control and efficient flow management. Typically comprising components such as nozzles, manifolds, temperature controllers, and split plates, these systems work in unison to ensure uniform distribution of molten plastic and seamless cavity filling.

Enhancing Production Efficiency

Hot runner technology introduces unprecedented precision and control to the injection molding process. By leveraging state-of-the-art heating elements, temperature controllers, and optimized flow channel designs, it eliminates defects and waste associated with cold runners. The technology significantly reduces cycle times by eliminating the need to open molds for removing cold sprues. Furthermore, hot runner systems support rapid color changes and simultaneous filling of multi-cavity molds, dramatically improving production efficiency and enabling manufacturers to respond swiftly to market demands.

Reducing Material Waste and Costs

By minimizing the generation of cold sprues, hot runner systems excel at reducing material waste, thereby cutting material costs. In conventional injection molding, large quantities of plastic often solidify in the flow channels and are discarded. Hot runner technology maximizes material utilization, not only reducing waste but also lowering the expenses associated with recycling or disposing of unused plastic, resulting in substantial cost savings for manufacturers.

Elevating Product Quality

Hot runner technology ensures consistent product quality through uniform heat distribution and precise melt delivery. This results in stable product dimensions and reliable mechanical properties. Moreover, the system enables the production of more intricate designs with higher precision, enhancing both the appearance and functionality of molded products to meet growing market demands for superior quality.

Environmental Benefits and Sustainability

As global emphasis on environmental sustainability intensifies, the eco-friendly attributes of hot runner technology have become increasingly significant. By reducing waste, this technology not only lowers production costs but also minimizes environmental impact. It aligns with modern sustainability goals, aiding manufacturers in achieving greener production processes that comply with environmental regulations and market trends.

Challenges and Future Prospects

While the advantages of hot runner systems are undeniable, their development has not been without challenges. Issues such as heat balance, flow control, and thermal distortion require ongoing research and innovation. Engineers and scientists are continually refining these systems to enhance their performance and adaptability, addressing the evolving needs of the industry.

Conclusion

In today’s quest for innovation and excellence, hot runner technology offers manufacturers a pathway to achieve simultaneous optimization of efficiency and cost control. As the technology matures and its applications deepen, there is every reason to believe it will continue to unlock new possibilities and drive the injection molding industry toward a brighter and more sustainable future.