Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

How to Prevent Hot Runner Temperature Overshoot with the TP01 Controller

What Causes Temperature Overshoot in Hot Runner Systems?

In hot runner systems, slight temperature overshoot during the startup phase is normal. Typically, the actual temperature may temporarily exceed the setpoint by ±2°C. Without proper control, excessive overshoot can cause part defects, longer startup times, and damage to mold components.

Why Choose TP01 Hot Runner Temperature Controller?

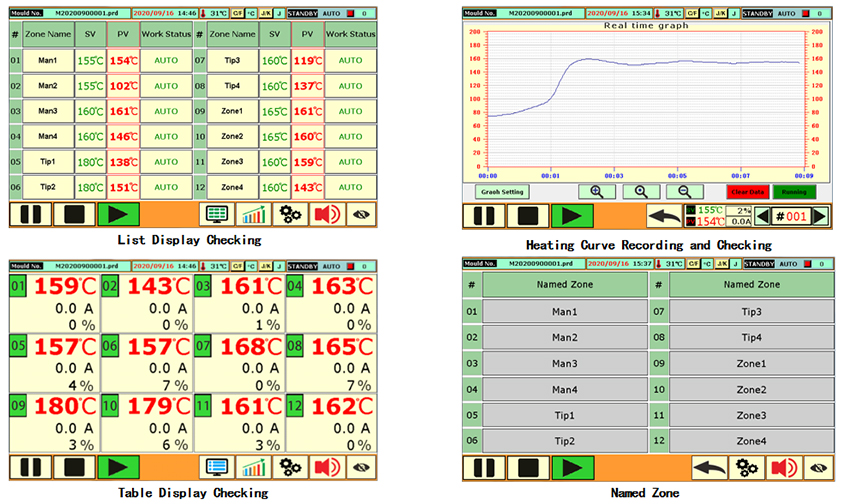

The TP01 hot runner temperature controller is specifically designed to minimize overshooting and stabilize mold temperatures efficiently. Thanks to its advanced technology, it ensures your production remains consistent and reliable.

Key Features That Control Temperature Overshoot:

1. FUZZY PIDD Control Algorithm

Unlike traditional PID controllers, the TP01 uses an intelligent FUZZY PIDD control system. It automatically adjusts heating output without manual tuning. When the deviation exceeds 0.5°C, the controller dynamically corrects it in real time, ensuring minimal overshoot and faster stabilization.

2. Second Derivative Response Function

TP01 doesn't just react to temperature differences — it also monitors the rate of temperature change. By predicting temperature trends, it effectively prevents overshooting before it happens.

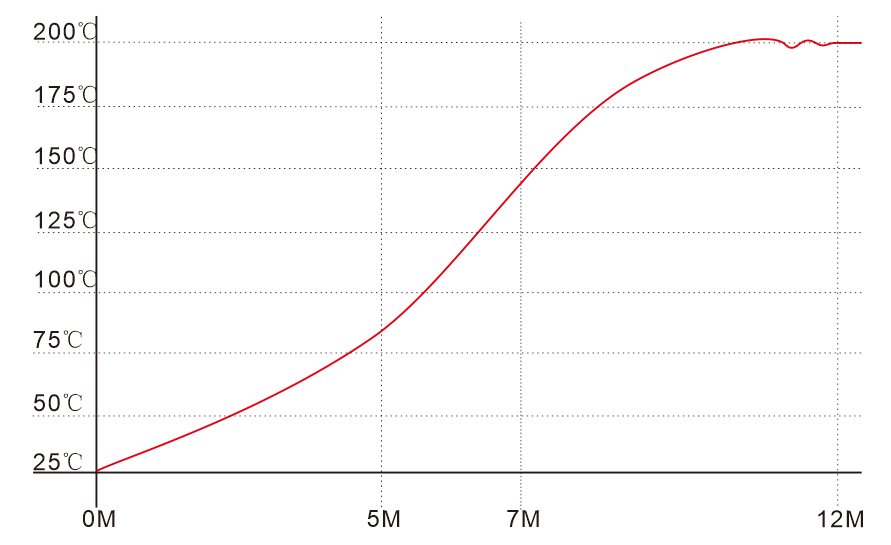

3. Soft-Start Heating

The TP01 applies a soft-start function, gradually increasing the heating output during startup. This protects heaters, prevents thermal shock, and ensures a smooth ramp-up to the target temperature.

Benefits of Using TP01 Temperature Controllers:

Faster startup times with stable temperatures

Enhanced part quality with minimal defects

Extended lifespan of heaters and mold components

Hassle-free automatic tuning — no manual adjustment needed

Experience Intelligent Temperature Control

With the TP01 series, achieving perfect hot runner temperature control has never been easier. Whether you’re running small molds or complex multi-cavity systems, TP01 helps you maintain precision with minimal operator input.

Ready to improve your injection molding performance?

Contact us today to learn more about the TP01 hot runner temperature controller!