Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

Temperature Control Card Operation Guide

What is a temperature control card?

Temperature control card is an electronic control module used to accurately monitor and adjust temperature, and is widely used in industrial automation, household appliances, laboratory equipment, etc. It usually consists of temperature sensors (such as thermocouples, thermal resistors), control circuits (PID algorithms), output drivers (relays, SSRs, thyristors), etc., and can automatically adjust the power of heating or cooling equipment according to the set temperature to ensure that the temperature is stable within the target range.

Main uses of temperature control cards

The core function of temperature control cards is precise temperature control. Specific uses include:

Heating control: such as hot runners of injection molding machines, hot beds of 3D printers, ovens, electric heaters, etc.

Refrigeration control: such as TEC semiconductor refrigeration, chillers, constant temperature boxes, etc.

Temperature monitoring and alarm: such as over-temperature protection of industrial equipment and maintenance of constant temperature environment in laboratories.

Energy-saving optimization: reduce temperature fluctuations and energy consumption through PID algorithms.

Basic Operation Instruction

1.Power-on Operation

a) Switch on the hot runner controller and checking each phase power data by power indicator;

b) Open the power button on the hot runner controller card;

c)It will enter into self-checking status, then to Auto work mode if switch on normally;

d)If soft-start setting is effectively, the module will enter into soft-start status and low pressure dehumidification; the auto mode indicator“Auto Mode Indicator” will flashing at this time.

e)After soft-start, the module will enter into auto work mode, the auto mode indicator “Auto Mode Indicator”will lighting all the time.

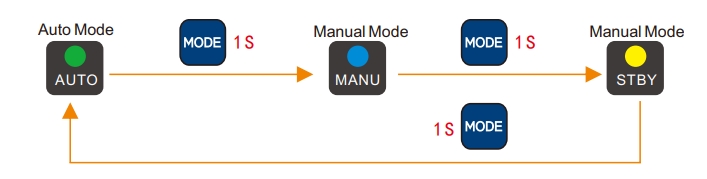

2. Work Mode Switching

In normal work status, pressing “made”1 sec to switch work mode

3. Temperature Adjustment

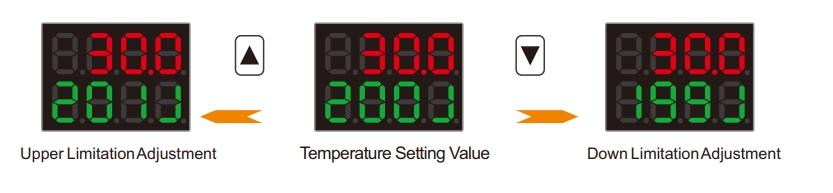

In Auto work mode, please click 【▲】or 【▼】 to up or down the setting temperature value, pressing the key can speed up the adjustment,

other work mode can not adjust temperature; After setting temperature , the setting temperature can be saved automatically.

Note: The Manual percentage adjustment only be effective in Manual mode, it usually use for the mould without thermocouple.

5. Checking Parameter In Auto Mode

In normal operation, the SV display setting temperature value, it can switch the display parameter by clicking“Parameter Checking Key”

6. Standby Operation Introduction:

The standby mode is use for insulation, it refers standby percentage and standby time, the insulation temperature= setting temperature

standby percentage, the insulation time is standby time. After finish the insulation time, it will return to auto mode automatically;

7. Preventing Misoperation Instruction

Lock Operation Instruction

Its purpose is to prevent users from misoperation , then entering into other mode or setting status. First please “Setup Key”click,then click “Parameter Checking Key” within 0.5 sec to lock the Mode key and Setup Key , the PV window will display LOCK and SV window display ON at this moment.

Note: The Lock key is in unlock status when the module work normally after switch on.

For more information about Special Operating Instruction, please contact us.

Operating Attentions

Please notify the note of power input connection method on the cabinet before installing the hot runner controller.

Please check the output connection way to match and connect the cable when connecting the mould.

The rated load current of hot runner controller card is 15A , please do not overload.

Please select the correct thermocouple type, otherwise it will appear big deviation when measuring the temperature.;

W hen the temperature is unstable, please check the supply power frequency is stable or not in operation parameter. If it is unstable, please choose PID SCR trigger method, if it still unstable, please select the PID self-tuning.

Please insert or pull out the card when the switch is powered off and insert the card along the slot;;

Please clean the card and dust-proof screen regularly;

P lease check the screws is fix or not regularly;

Please pay attention to moisture and oxidation when preserve hot runner controller cards.