In modern injection molding, precision is not optional—it is fundamental. At the center of th...

Custom Hot-Runner Temperature Control Solutions for Multi-Cavity Molds — Cut Debugging Time by 50%

Introduction

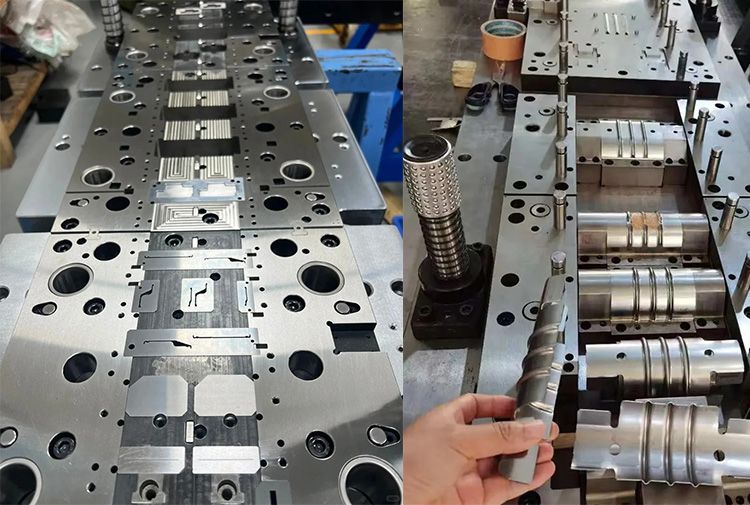

Multi-cavity molds are the backbone of high-volume injection production: more cavities mean lower part cost and faster throughput. But more cavities also mean more potential for temperature imbalance, longer setup and repeated debugging. A tailored hot runner temperature control solution — especially one that supports many zones and smart control logic — is the difference between hours of trial-and-error and a fast, repeatable production start.

Multi Cavity Mold Hot Runner Temperature Control System Case Study: The Cost Of Poor Control

When temperature varies between cavities, common defects appear: short shots, burn marks, sink marks, color variations and dimensional drift. This section explores a multi-cavity mold hot runner temperature control system case study in which teams using conventional PID controllers spent days tuning parameters. Replacing that approach with a smart, adaptive multi-zone controller reduced setup iterations and cut total debug time roughly in half.

Hot Runner Temperature Control System Customization: From Requirement Analysis To Implementation Process

A structured approach avoids guesswork:

Requirement analysis — map cavity count, manifold geometry, heater band layout, thermocouple locations, and resin type.

Zone design — define control zones so that each heater/thermocouple pair controls the region that matters most for melt balance.

Controller selection — choose a controller that supports the number of zones you need (for example, 6–120 zones) and offers features like data logging and LAN monitoring.

Installation & wiring — follow wiring best practices to minimize noise and ensure accurate thermocouple reading.

Soft start & phased ramping — protect material and avoid thermal shock during startup.

Automatic stabilization — use adaptive control so the system finds optimal outputs without extensive manual PID tuning.

Production validation & monitoring — record temperature curves, export logs, and use them for continual improvement.

Following this hot runner temperature control system customization, from requirement analysis to implementation process, prevents many common issues and makes commissioning predictable.

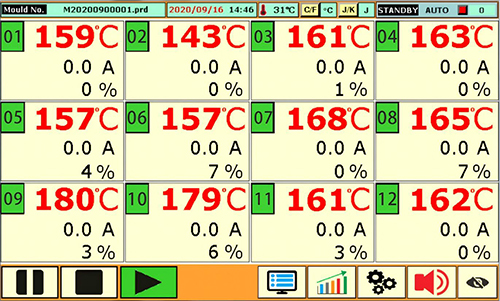

How To Use Touch-Screen Multi-Zone Controller To Shorten Mold Debugging Time

Modern controllers with touch-screen interfaces and smart control algorithms simplify commissioning:

Use the touchscreen to quickly set zone names, targets, and startup profiles.

Load saved temperature recipes to reproduce prior successful setups.

Leverage automatic features so the controller self-tunes rather than requiring manual PID fiddling.

Monitor 10×/sec sampling (or similar high-frequency sampling) to spot transient deviations during trial shots.

This is exactly how to use a touch-screen multi-zone controller to shorten mold debugging time—less manual trial, faster stabilization, and quicker approval for production.

6-120 Zone Hot Runner Controller In Injection Molds — HY20 Series

For high-cavity molds, you need a controller that scales. The HY20 Series Touch-Screen Multi-Zone Controller (6–120 zones) is built to:

Support 6–120 control zones (modular, scalable)

Run FUZZY-PIDD control — automatic adaptation to different heating models without manual tuning, minimizing setup time

Provide an easy, user-friendly touch-screen HMI with multi-language support

Enable data import/export and temperature record storage for traceability

Offer LAN network control (optional) for centralized monitoring — showing the multi-zone hot runner controller data logging and network monitoring value for quality teams

Sample thermocouples 10 times per second for precise feedback

Include humanized mechanical design (good coating, dust-proof, excellent heat dissipation, tool-free maintenance)

These capabilities directly address 6-120 zone hot runner controller in injection mold applications and are engineered to cut commissioning iterations.

FUZZY-PIDD Control Advantages For Hot Runner Systems

Traditional PID tuning can be time-consuming and sensitive to changes in the mold or material.

FUZZY-PIDD blends fuzzy logic with PID principles so the controller:

Automatically adjusts control behavior to the heater model and load

Reduces the need for manual parameter tuning during mold trials

Improves stability when ambient conditions or resin grades vary

The result: fewer tuning cycles and faster time-to-production.

Multi-cavity Mold Debugging: Common Temperature Control Issues And Solutions

Common problem → practical fix:

: One cavity runs colder → Solution: verify thermocouple placement, check heater connection, and reassign a dedicated control zone rather than grouping dissimilar heaters.

: Temperature oscillation after heat up → Solution: use adaptive FUZZY-PIDD control or enable soft start / phased output to avoid large overshoot.

: Environmental drift (shop temp changes) → Solution: monitor ambient internal temperature and use trend logs to compensate.

These examples illustrate common temperature control issues and solutions for multi-cavity mold debugging that you’ll apply during commissioning.

Multi-zone Hot Runner Controller Data Logging And Network Monitoring Value

Data matters. Capturing and exporting temperature records lets teams:

Compare runs to find the ideal temperature recipe

Prove compliance and process capability to customers

Remotely monitor production with LAN connectivity for centralized alerts

This is the practical multi-zone hot runner controller data logging and network monitoring value for modern factories.

Selection Tips: Multi-cavity Mold Temperature Control System Selection Tips

When choosing a controller, prioritize:

Zone count and modular scalability (so you don’t outgrow the controller)

Smart control algorithms (to avoid manual tuning)

Data logging and export (traceability is non-negotiable)

High sampling frequency for accurate thermocouple feedback

Robust industrial design (dust-proof, good dissipation, tool-free maintenance)

These multi-cavity mold temperature control system selection tips ensure you pick a solution that reduces startup friction and long-term maintenance.

Real Benefits — How This Approach Helps Mold Manufacturers Improve Yield And Efficiency Via Temperature Control

By combining a customized zone layout, FUZZY-PIDD adaptive control and a modern touch-screen multi-zone controller, manufacturers realize:

Up to 50% reduction in debugging & setup time (fewer tuning cycles, faster stabilization)

Higher first-pass yield thanks to better temperature consistency (hot runner temperature consistency importance)

Easier reproducibility of successful runs with recipe save/load and data export

Faster troubleshooting using real-time indicators and trend logs

In short: better control = less waste + faster ramp to production.

Call to Action

Suppose you run multi-cavity molds and want to shorten setup and debugging time. In that case, a custom hot-runner temperature control solution with a touch-screen multi-zone controller is the fastest path to repeatable quality. The HY20 Series (6–120 zones) combines FUZZY-PIDD adaptive control, high-frequency thermocouple sampling, data logging, and LAN monitoring to transform commissioning from a headache into a predictable, efficient process.

Ready to cut debugging time by up to 50%?

Explore the HY20 Touch-Screen Multi-Zone Controller (6–120 zones) and request a custom selection guide:

https://www.cntopower.com/plchotrunnercontroller/