Contents1. Why cold runners drive waste in medical molding2. Eliminating Cold Runner Waste with hot ...

Everything You Need to Know About PET Bottles and Their Manufacturing Process

Introduction

Ever wondered how a simple PET bottle goes from tiny resin pellets to the bottle you drink from every day?

The process behind PET bottle manufacturing is a combination of chemistry, precision engineering, and sustainability innovation. Let’s explore how PET plastic bottles are made step by step.

What Is a PET Bottle?

PET bottle is a type of plastic container made from Polyethylene Terephthalate (PET), a strong, lightweight, and recyclable thermoplastic polymer. PET is part of the polyester family and is derived from ethylene glycol and terephthalic acid. Because of its clarity, strength, and excellent barrier properties, PET is one of the most widely used materials for packaging beverages, water, and food products.

Compared with other plastics like HDPE or PVC, PET plastic bottles stand out for their transparency and recyclability. They are safe for contact with food and beverages and are approved by global health and safety organizations, including the FDA and EFSA.

Key Properties of PET Bottles

Lightweight: PET bottles are significantly lighter than glass, reducing transportation costs and emissions.

Durable: Despite being lightweight, PET has excellent impact resistance.

Transparent: PET provides high clarity, allowing consumers to see the product inside.

Chemical Resistance: PET does not react with food or drinks, maintaining product integrity.

Recyclable: PET can be recycled multiple times without significantly compromising its original strength.

Common Applications of PET Bottles

Beverage Industry

The beverage sector is by far the largest consumer of PET bottles worldwide.

Carbonated Soft Drinks (CSD): PET bottles can withstand internal pressure from carbonation, making them ideal for soda and sparkling beverages.

Bottled Water: Lightweight PET bottles reduce transportation costs while maintaining the safety and purity of the water.

Juices and Energy Drinks: PET’s clarity allows consumers to see the product, and UV-blocking additives can protect color-sensitive beverages.

Dairy and Tea Drinks: Special PET grades with barrier coatings help extend shelf life for milk-based and tea products.

Food Packaging

Beyond beverages, PET plastic bottles are widely used for food-grade packaging due to their excellent oxygen and moisture resistance.

Common PET food applications include:

Edible Oils and Vinegar: PET’s chemical resistance keeps oils fresh without affecting flavor.

Sauces, Condiments, and Dressings: PET bottles are lightweight, squeezable, and compatible with high-speed filling lines.

Honey and Syrups: PET’s transparency enhances shelf appeal, while its strength prevents leaks.

PET bottles can also be coated with oxygen barrier layers to protect sensitive foods from oxidation and spoilage.

Pharmaceutical and Healthcare Industry

In the pharmaceutical sector, PET bottles offer safety, purity, and protection.

They are used to package:

Liquid medicines and syrups

Nutritional supplements

Vitamins and herbal extracts

PET provides a non-reactive, hygienic packaging solution that complies with FDA and EU standards. Amber-colored PET bottles are often used to block UV rays and protect light-sensitive formulations.

Cosmetics and Personal Care Products

PET packaging is also a favorite in the cosmetics and personal care industry for its premium appearance and versatility.

Applications include:

Shampoos, conditioners, and hair serums

Lotions, body oils, and creams

Perfumes and sprays

PET’s high gloss finish, customizable shapes, and color flexibility allow brands to create visually appealing designs that enhance consumer perception.

Additionally, PET’s compatibility with recycled materials (rPET) aligns with the beauty industry’s growing sustainability goals.

Industrial and Chemical Packaging

For non-food liquids such as lubricants, automotive fluids, and laboratory chemicals, PET bottles offer a safe, transparent, and durable option.

PET’s excellent chemical resistance prevents contamination or degradation, while its lightweight design reduces shipping costs for bulk liquids.

Health and Wellness Products

PET packaging is also expanding in the health and wellness market:

Protein shakes and nutritional drinks

Dietary supplements

Plant-based beverages and smoothies

Its clean aesthetic, recyclability, and lightweight design align perfectly with brands emphasizing health, sustainability, and lifestyle convenience.

Why PET Bottles Are So Popular

The global popularity of PET bottles stems from their balance between performance and sustainability. They offer:

Lower production costs compared to glass or metal packaging.

High durability and portability for consumers.

Compatibility with recycling systems and circular economy initiatives.

In recent years, rPET (recycled PET) has become a growing trend — manufacturers melt down used PET bottles to produce new ones, significantly reducing waste and energy consumption.

How PET Bottles Are Made?

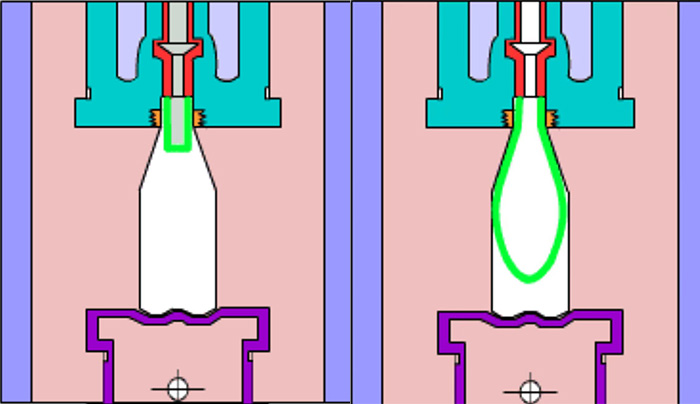

The main process for producing PET plastic bottles is blow molding. Blow molding is a manufacturing technology used to produce hollow plastic products. This process is mainly completed by blow molding and is suitable for producing bottles, barrels, cans, containers, and other hollow products.

A Step-by-Step Guide

Material Preparation: Thermoplastic plastic pellets, such as polyethylene (PE) and polypropylene (PP), are used.

Pre-melting: Plastic pellets are fed into the heating section of the blow molding machine and heated in the hopper until they are molten.

Injection and Blowing: The molten plastic is injected through one or more nozzles into a hollow tubular structure formed by a mold. During this process, the air in the mold is compressed, forming the hollow plastic product.

Inflation: After the plastic tubular product cools and solidifies, it is moved to the working area of the blow molding machine, where air is blown in to expand it to the desired shape and size.

Cooling and Setting: The blow-molded product requires further cooling to maintain its shape and stability.

Post-Processing: Some products may require further processing such as cutting, polishing, and printing to meet final product quality requirements.

Inspection: Product quality is inspected to ensure that it meets specified standards and customer requirements.

What are the molding conditions for PET?

Material Preparation: Thermoplastic pellets, such as polyethylene (PE) and polypropylene (PP), are used.

Pre-melting: The plastic pellets are fed into the heating section of the blow molding machine and heated in the hopper until they are molten.

Injection and Blowing: The molten plastic is injected through one or more nozzles into a hollow tubular structure formed by a mold. During this process, the air in the mold is compressed, forming the hollow plastic product.

Inflation: After the plastic tubular product cools and solidifies, it is moved to the working area of the blow molding machine, where air is blown in to expand it to the desired shape and size.

Cooling and Setting: The blow-molded product requires further cooling to maintain its shape and stability.

Post-Processing: Some products may require further processing such as cutting, polishing, and printing to meet final product quality requirements.

Inspection: The product undergoes quality inspection to ensure that it meets specified standards and customer requirements.

Conclusion

PET bottles have become a global standard for packaging due to their perfect balance of clarity, strength, safety, and recyclability. They provide manufacturers with lightweight, cost-effective solutions while maintaining product integrity and aesthetic appeal. With increasing consumer awareness of sustainability, the demand for recycled PET (rPET) and eco-friendly packaging innovations continues to grow.

Looking to Optimize Your PET Bottle Production?

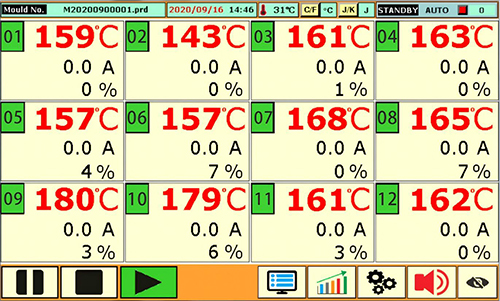

At CNTopower, we specialize in providing precision Hot Runner Temperature Controllers designed to enhance injection molding efficiency and ensure consistent product quality.

A stable and precise temperature control system is crucial for producing high-quality PET preforms and bottles with uniform wall thickness, clarity, and strength.

Learn more about how our solutions can help you achieve higher productivity and energy savings in your PET molding process:

https://www.cntopower.com/HotRunnerTemperatureController/

FAQ

Are PET bottles safe for food and beverages?

Yes, PET bottles are approved by FDA and EFSA for food contact and are safe for packaging beverages and consumables.

Can PET bottles be recycled?

Absolutely. PET is 100% recyclable and can be reprocessed into rPET for new bottles, textiles, or packaging materials.

What is the difference between PET and other plastics?

Compared with HDPE or PVC, PET is lighter, more transparent, and offers better gas and moisture barrier properties.