In modern injection molding, precision is not optional—it is fundamental. At the center of th...

Differences Among Injection Molding, Blow Molding, Blister Molding, and Extrusion Molding: A Complete Comparison Guide

When it comes to plastic manufacturing, choosing the right forming process is essential for achieving the perfect balance between quality, cost, and production efficiency. The four most widely used plastic forming processes are injection molding, blow molding, blister (thermoforming) molding, and extrusion molding.

Although all of them start with molten plastic, they differ greatly in how the material is shaped, cooled, and finished. In this guide, we’ll explain how each process works, their common applications, materials used, advantages and disadvantages, and when to choose one over the other.

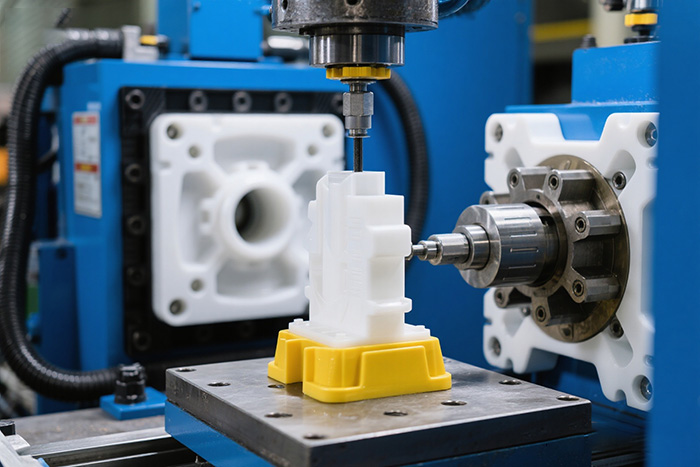

What Is Injection Molding?

Injection molding is one of the most precise and versatile plastic manufacturing methods. In the injection molding process, molten plastic is injected under high pressure into a closed steel mold cavity. After cooling and solidifying, the part is ejected, and the cycle repeats.

Typical Applications

Injection molding is ideal for complex, high-precision parts such as electronic housings, connectors, gears, toys, and medical components.

Common Materials

ABS, PP, PE, PC, PA (nylon), POM, PS, and TPU are commonly used.

Advantages

Excellent dimensional accuracy and consistency (tolerance ±0.05–0.3 mm).

Capable of producing detailed features and thin walls.

Highly repeatable and efficient for mass production.

Disadvantages

High initial mold tooling cost and longer lead time.

Not economical for low-volume production.

Typical Defects

Sink marks, warpage, short shots, flash, and weld lines.

If your product demands tight tolerances, complex geometry, or an aesthetic surface finish, injection molding is almost always the best choice.

What Is Blow Molding?

Blow molding is designed for making hollow plastic parts such as bottles, tanks, and containers. The process involves forming a molten plastic tube (called a parison) or preform, enclosing it in a mold, and blowing air inside to expand it against the mold wall.

Variants

There are three main types:

Extrusion Blow Molding (EBM)

Injection Blow Molding (IBM)

Injection Stretch Blow Molding (ISBM) — commonly used for PET beverage bottles.

Common Materials

PE, PP, PET, PVC, and HDPE.

Advantages

Excellent for producing lightweight, hollow containers.

High production rates for bottles and similar parts.

Relatively lower material waste compared to other processes.

Disadvantages

Limited precision compared to injection molding.

Uneven wall thickness in certain designs.

Typical Defects

Wall-thickness variation, neck deformation, weld line marks.

If you’re comparing blow molding vs injection molding, remember that blow molding is the go-to choice for hollow shapes, while injection molding excels in detailed solid parts.

What Is Blister Molding (Thermoforming)?

Blister molding, also known as thermoforming, is a process where a plastic sheet is heated until soft, then vacuum-formed over a mold to create the desired shape. After cooling, the formed sheet is trimmed to produce the final product.

Typical Applications

Thermoforming is widely used for plastic packaging, including clamshells, trays, and blister packs. It’s also used for large, shallow components such as appliance panels or display covers.

Common Materials

PVC, PET, PS, HIPS, and ABS sheet.

Advantages

Low tooling cost and fast prototype turnaround.

Ideal for large parts or thin packaging applications.

Short lead time — perfect for low to medium-volume production.

Disadvantages

Lower dimensional accuracy and less detail compared to injection molding.

Material waste due to trimming.

Typical Defects

Webbing, surface marks, uneven wall thickness.

For cost-sensitive packaging and shallow parts, thermoforming plastic packaging (or blister molding) is the most economical and efficient method.

What Is Extrusion Molding?

Extrusion molding, or simply plastic extrusion, is used to make continuous profiles such as pipes, sheets, films, and rods. The molten plastic is forced through a die that defines its cross-sectional shape, then cooled and cut to length.

Typical Applications

Pipes, tubing, weatherstrips, plastic trim profiles, sheets, and films.

Common Materials

PE, PP, PVC, ABS, PS, and PC.

Advantages

Continuous, high-efficiency production.

Simple tooling compared to injection molds.

Excellent material utilization with minimal scrap.

Disadvantages

Limited to uniform cross-sections (cannot form complex 3D shapes).

Dimensional variations due to cooling control.

Typical Defects

Die lines, melt fracture, bubbles, or uneven surface finish.

If your product requires continuous plastic profiles or sheets, the extrusion molding process offers the best balance of cost and throughput.

Key Differences at a Glance

| Molding Type | Material State | Product Type | Production Scale | Key Advantages |

| Injection Molding | Molten plastic injected into mold | Solid, complex parts | High volume | Precision, repeatability |

| Blow Molding | Heated parison inflated in mold | Hollow parts | High volume | Lightweight, low material use |

| Blister Molding | Heated sheet formed over mold | Thin packaging | Medium scale | Low cost, transparency |

| Extrusion Molding | Molten plastic pushed through die | Continuous shapes | Continuous | Fast production, low cost |

How to Choose the Right Process

Here’s a quick rule of thumb for selecting the best plastic molding process:

Need precision and fine detail? → Choose injection molding.

Need hollow containers like bottles or tanks? → Choose blow molding.

Need packaging or shallow shells quickly and cheaply? → Choose blister (thermoforming).

Need continuous shapes such as tubes, films, or trim? → Choose extrusion molding.

Each process has its unique strengths. Selecting the right one depends on your part geometry, production volume, and budget.

Final Thoughts

Although injection molding, blow molding, blister molding, and extrusion molding all transform molten plastic into useful shapes, the choice between them can make a huge difference in cost, performance, and appearance.

By understanding their differences — from tooling investment to achievable tolerances — you can make informed decisions and optimize both design and manufacturing efficiency.

If you’re developing a new plastic product and unsure which molding process fits best, consult with a professional plastic molding manufacturer. They can provide guidance on materials, tooling design, and cost estimation to ensure you get the best outcome for your project.

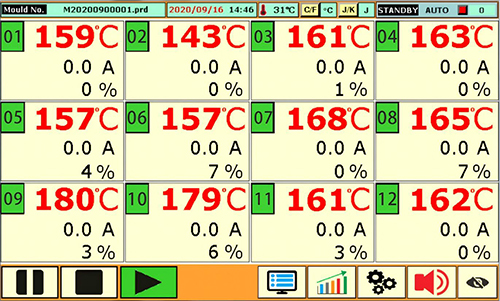

Optimize Your Production with CNTOP Hot Runner Temperature Controllers

If you use injection molding in your manufacturing process, precise temperature control is key to maintaining consistent product quality and reducing waste.

At CNTOP, we provide advanced Hot Runner Temperature Controllers designed to optimize injection molding performance.

Why Choose CNTOP:

Accurate and stable temperature control

Improved cycle efficiency and product consistency

Energy-saving operation for sustainable production

Custom solutions for various mold configurations

Boost your molding efficiency today—visit CNTOP Hot Runner Temperature Controller to learn more or get a free quote now.