Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

How Has Plastic Injection Moulding Contributed to Your Halloween Products?

Introduction

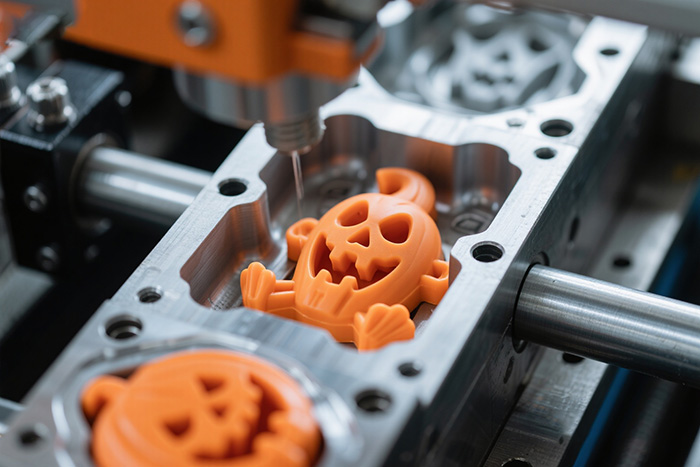

Every Halloween season, shelves fill up with colorful, creative, and spooky products — from plastic Halloween pumpkins to Halloween plastic cups and plastic Halloween buckets. But have you ever wondered how these festive items are made? The answer lies in one of the most efficient and versatile manufacturing technologies: plastic injection molding.

This process has revolutionized how Halloween decorations and accessories are produced, allowing manufacturers to deliver large volumes of detailed, durable, and affordable products in time for the spooky season.

The Role of Plastic Injection Molding in Halloween Product Manufacturing

Let’s explore how this technology contributes to the Halloween industry and shapes the fun items we all love.

Bringing Plastic Halloween Pumpkins to Life

Plastic pumpkins are among the most iconic Halloween products. Using injection molding, manufacturers can produce pumpkins with intricate facial details and smooth finishes. Unlike paper or ceramic options, plastic Halloween pumpkins are lightweight, durable, and reusable year after year.

The ability to customize molds allows designers to experiment with different colors, facial expressions, and lighting options, making every pumpkin unique and eye-catching.

Producing Durable Halloween Plastic Cups

At Halloween parties and themed events, Halloween plastic cups are essential. Injection molding ensures each cup has consistent wall thickness, making it strong enough to hold both hot and cold beverages. The process also supports custom designs, enabling brands to add spooky graphics, such as ghosts, bats, or witches, directly onto the plastic surface through molded-in decorations or post-printing.

Creating Lightweight and Colorful Plastic Halloween Buckets

Plastic Halloween buckets are a trick-or-treating staple for kids. Injection molding allows manufacturers to produce them in large quantities while maintaining lightweight durability. The use of food-grade plastics ensures safety, while bright orange, black, and purple pigments add festive appeal. Some molds even incorporate ergonomic handles for better grip — perfect for a long night of candy collecting.

Designing Realistic and Comfortable Plastic Halloween Masks

Plastic Halloween masks are another popular product of injection molding. This process enables the creation of fine facial details and smooth surfaces, making masks look more lifelike. The flexibility of thermoplastics also ensures comfort and safety for wearers. Compared to paper or metal alternatives, injection-molded masks are more affordable, safer for children, and easier to decorate with paint or stickers.

Advantages of Plastic Injection Molding for Halloween Products

Here’s why injection molding continues to dominate seasonal product manufacturing:

High production speed: Perfect for meeting seasonal demand surges.

Design flexibility: Manufacturers can easily change molds to create different product lines.

Durability: Products like plastic Halloween buckets and cups can be reused for years.

Cost-effectiveness: Once the mould is made, large-scale production becomes highly economical.

Eco-friendly potential: Modern techniques allow the use of recycled or biodegradable plastics.

Supporting Creative DIY Projects

Plastic injection molding not only supports mass production but also inspires DIY Halloween projects. For instance, the popular DIY Halloween pumpkin paper mache plastic bag trend often combines reusable plastic bases with paper or eco-friendly materials. These hybrid creations blend traditional crafts with the modern convenience of molded plastic parts, allowing individuals to express creativity while reducing waste.

Sustainability in Modern Halloween Manufacturing

Today’s manufacturers are also focusing on sustainable plastic molding. By using recycled materials, energy-efficient machines, and lightweight designs, it’s possible to reduce environmental impact without sacrificing product quality. The result is a new generation of eco-conscious Halloween products — durable, safe, and sustainable.

Conclusion

From plastic Halloween pumpkins glowing on porches to plastic Halloween buckets filled with candy, injection molding has made Halloween celebrations more vibrant and accessible. This technology enables the production of fun, affordable, and high-quality products that bring joy to millions of people around the world every October.

Whether you’re hosting a spooky party, trick-or-treating with kids, or crafting a DIY Halloween pumpkin paper mache plastic bag, you’ve already experienced the power of plastic injection molding — the invisible hero behind your Halloween magic.

Why Topower Is Your Injection Molding Partner

For manufacturers of seasonal items like plastic Halloween pumpkins, Halloween plastic cups, plastic Halloween buckets, and plastic Halloween masks, process stability is everything. CNTOPower’s Hot Runner Temperature Controller helps you keep that stability — precise, multi-zone temperature control ensures consistent melt flow and repeatable cycle-to-cycle performance across complex hot runner systems. The result: fewer rejects, better surface finish and color consistency, faster cycle times, and lower material waste — all of which matter when you’re producing high volumes for the Halloween season.

Designed for easy integration into production lines, the controller offers fast response, reliable alarms, and intuitive controls so operators spend less time troubleshooting and more time running parts. Whether you’re scaling up production for trick-or-treat season or refining premium, reusable Halloween pieces, CNTOPower’s Hot Runner Temperature Controller can help improve yield and reduce operating costs.

Learn more or request a quote: https://www.cntopower.com/HotRunnerTemperatureController/