Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

Top Benefits of Using Sequential Valve Gate Technology in Injection Molding

Sequential valve gate systems (also called sequential valve gating or sequential gating) let molders open and close individual hot-runner nozzles in a controlled sequence instead of letting all gates fill at once. For complex multi-cavity molds and precision parts, that control translates directly into better part quality, fewer defects, and higher process efficiency. This article explains the top benefits of sequential valve gate technology, how it works with hot-runner temperature and control systems, and practical considerations for adopting it.

Why Sequential Valve Gates Matter

Traditional simultaneous gating can create uneven fill patterns, imbalanced flow, and stress concentrations in parts — especially when cavities are far apart or when molds produce thin‐walled or aesthetic components. Sequential valve gates let you control the order and timing of gate opening so that melt front progression, packing, and cooling can be optimized for each cavity. The result: more consistent parts, easier process window development, and fewer rejects.

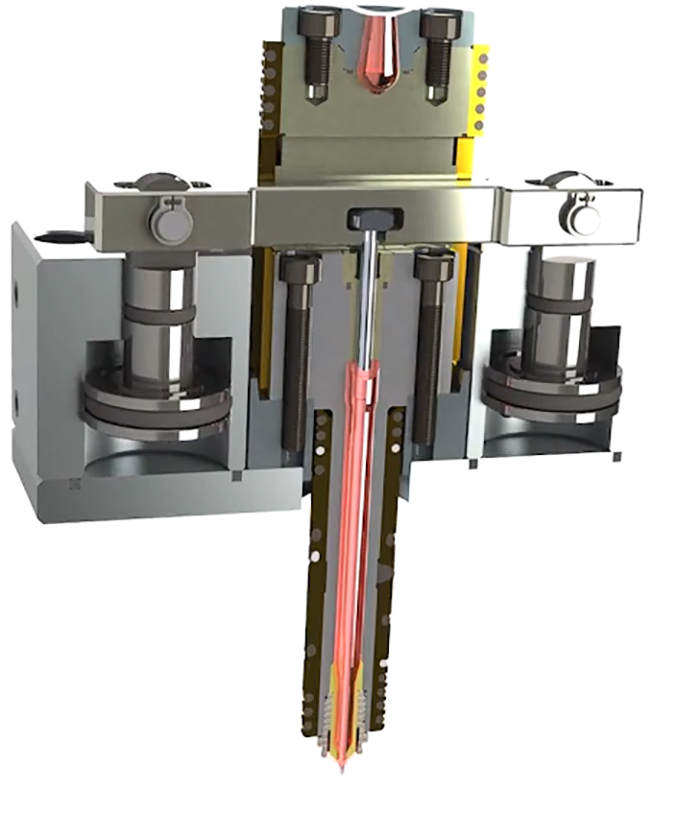

As Tinko points out, the key is using hydraulic or pneumatic cylinders to drive the valve devices so that each gate can be independently controlled (open/close) during injection.

Key benefits

Improved part quality and dimensional consistency

By controlling the sequence and timing of gate openings, you can ensure melt fronts meet in predictable locations and under controlled pressure. That reduces common defects such as:

Weld lines and flow marks (they form in controlled, less-visible locations). In fact, Tinko explicitly lists “eliminates weld lines” as a technical characteristic of sequential valve gate controllers.

Sink and void formation (better, staged packing reduces localized shrinkage).

Warpage and dimensional variability (more uniform cooling and packing across cavities). Tinko also mentions that wall thickness becomes more uniform, reducing defects such as shrinkage and warping.

Reduced flash and gate vestige

Sequentially opening gates avoids simultaneous high-pressure surges across all gates, which can force material out of parting lines and produce flash. It also allows optimized gate shear/hold profiles so the gate vestige is cleaner and easier to trim or polish — important for visible surfaces.

The Tinko article highlights that sequential filling reduces molding pressure — “reduces molding pressure” is one of their listed benefits.

Lower scrap rates and rework

Better managed fill and pack phases translate into fewer out-of-spec parts. For multi-cavity tooling, sequential gating is especially valuable: instead of losing many cavities to a single imbalance or defect mode, you get higher overall yield and fewer manual reworks.

Smaller process window but greater controllability

Sequential gating narrows the variability sources by making the filling stage more deterministic. Although this can mean a tighter process window to manage, it gives molders finer control — and with a proper control system (valve gate sequencer + temperature controller) the process becomes repeatable and robust.

Optimized filling for thin-walled and technical parts

Parts with thin walls, long flow lengths, or specific cosmetic demands benefit from staged filling. Sequential valves allow you to direct melt flow path intentionally so shear, pressure, and heat history are favorable for the part geometry. Tinko points out that this approach “shortens molding cycle” because filling efficiency is improved.

Reduced internal stresses and improved mechanical properties

When cavities are packed sequentially and with controlled pressure profiles, internal residual stresses are often reduced. That helps parts maintain dimensional stability over time and can modestly improve mechanical properties (less stress-related distortion). Tinko mentions improved product quality via more uniform wall thickness and reduced warping.

Energy and material savings

Sequential gating can reduce the need for excessive hold pressure and overpacking to compensate for imbalances. Over time that can lower energy use per part (less machine work and shorter corrective cycles) and reduce material waste from scrapped runs.

Easier troubleshooting and faster setup

When defects occur, sequential systems make root-cause analysis simpler because you can isolate the sequence and gate timing as variables. During commissioning or mold trials, valve gate timing adjustments let engineers dial in proper filling without changing tooling.

Better suitability for multi-material and family molds

For overmolding, insert-molding, or family molds with cavities of different volumes/geometry, sequential gate control is often essential to achieve uniform quality across dissimilar cavities.

Compatibility with automation and inline inspection

Because sequential valve gates are driven by programmable sequencers and electronic controllers, they integrate cleanly with automated production lines, robotic part removal, and inline inspection systems — supporting higher throughput with consistent quality.

How sequential valves work with temperature and control systems

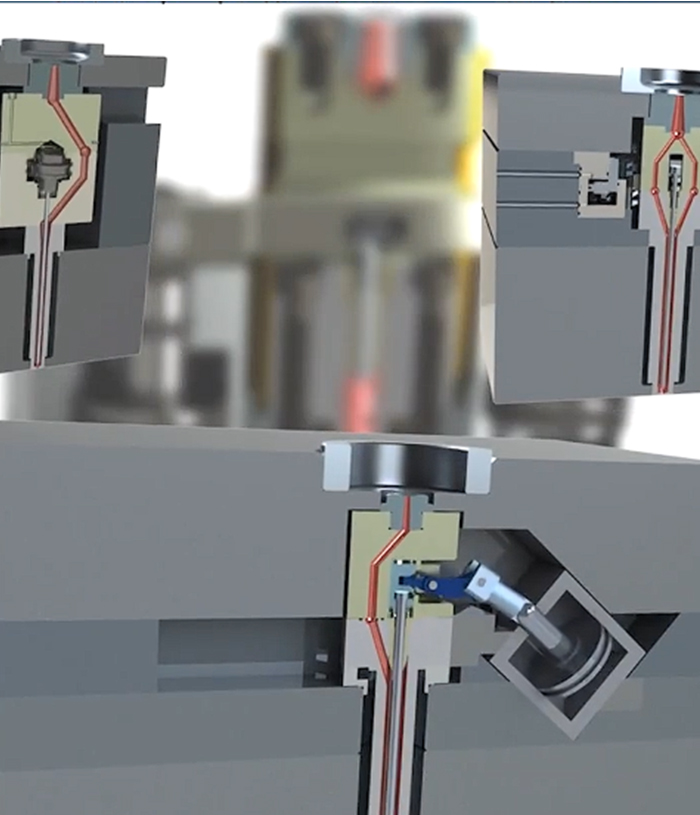

Sequential gating relies on two control layers:

Valve gate actuation/sequencing — a dedicated sequencer (electro-pneumatic or fully electric) opens/closes gates based on a programmed time or sensor feedback. Tinko lays out the “application steps” of the sequential valve gate technique, which typically include: injection start (open central gate), close central gate & open side gates, then pressure hold, then cooling & part removal.

Hot-runner temperature control — stable, accurate nozzle temperatures ensure viscosity and flow behavior are consistent between gates and during sequential steps. Good hot-runner temperature control ensures repeatability of melt fill and avoids one gate fat-filling while another lags (which would defeat the sequencing benefit).

As a manufacturer of hot-runner control systems, you are well-positioned to integrate both valve gate sequencing and temperature control into a unified solution — emphasizing that precise temperature stability supports the sequence logic.

Practical considerations before adopting sequential valve gates

Tooling cost vs. yield benefits: Valve gate systems add upfront cost (valves, actuators, sequencer), but ROI often comes from reduced scrap and faster qualification on complex molds. The Tinko article mentions that the technology is especially valuable for large or complex parts where mold balance is difficult.

Maintenance: Valve tips and actuators require periodic inspection and maintenance to avoid sticking or delayed response.

Control strategy: Decide between time-based sequencing (simple, low-cost) and sensor-based or pressure-feedback sequencing (higher control, better for challenging geometries). Tinko suggests independent control of each gate (hydraulic or pneumatic cylinder) to fulfill the technical principle.

Integration: Ensure your hot-runner temperature controller and sequencer can communicate or be synchronized via PLC or process controller for repeatable runs.

Best practices

Start with a gate-timing study during mold design and prototyping.

Use high-quality hot-runner temperature controllers — nozzle temperature stability supports repeatability.

Implement a phased approach (time-based, then refine to feedback-based) if you’re new to sequencing.

Keep valve internals and tips clean and replace worn components promptly.

For multi-cavity molds, map out cavity layout and simulate melt-front progression to design the sequence.

Emphasize training of molding technicians in the logic of sequential gating (timing, feedback, mold-machine interface).

Conclusion

Sequential valve gate technology delivers tangible advantages for precision molding: better cosmetic appearance, improved dimensional control, lower scrap, and streamlined troubleshooting. For complex multi-cavity moulds, family molds, thin-walled parts, or parts with tight cosmetic requirements, the extra control is often the difference between acceptable and outstanding production quality.

If you use sequential valve gating, pairing it with a reliable hot-runner temperature controller is essential. For robust nozzle temperature stability and tight process control, consider solutions designed for hot-runner systems and sequential gating integration.