Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

Polycarbonate Injection Molding: A Practical Guide for Manufacturers and Design Engineers

Introduction

Polycarbonate injection molding is a widely used process for producing durable, optically clear, and heat-resistant plastic parts. From automotive headlamp lenses to protective equipment and medical housings, polycarbonate parts combine toughness with precision. However, molding this material requires careful control of processing conditions to achieve consistent quality. This guide explains the basics of polycarbonate, molding methods, process steps, advantages, common applications, and challenges — plus practical tips on how precise hot-runner temperature control can improve results.

Understanding Polycarbonate

Polycarbonate (PC) is an amorphous thermoplastic known for its excellent impact resistance, dimensional stability, thermal resistance, and optical clarity. It is hygroscopic — it absorbs moisture — and has a relatively high melt temperature compared with many commodity plastics. These properties make PC ideal for demanding applications but also require appropriate drying, melt handling, and mold-temperature management to avoid defects such as hydrolytic degradation, splay (surface streaks), or internal voids.

Key material characteristics:

High impact strength and toughness

Good heat resistance (useful up to ~100–135°C depending on grade)

Optical clarity (some grades) and good dimensional stability

Sensitive to moisture and shear; needs controlled processing

Types of Polycarbonate Molding

Although the keyword focus is polycarbonate injection molding, it's useful to understand other molding methods used with PC:

Injection Molding

The most common method for producing complex, high-precision polycarbonate parts. Polymer is melted, injected into a closed mold under pressure, cooled, and ejected. Injection molding excels at repeatability and surface finish.

Blow Molding

Used for hollow polycarbonate items (less common than for PET or HDPE). A parison is extruded and inflated to form hollow shapes like containers or enclosures.

Thermoforming

Thermoforming involves heating a polycarbonate sheet and forming it over a mold. Suited to large, relatively simple shapes (e.g., machine covers, signage) where injection-molding tooling cost would be prohibitive.

Rotational Molding

Rare for polycarbonate due to molecular weight and processing window; used for large hollow parts when appropriate resins and process controls are available.

The Polycarbonate Molding Process

A typical polycarbonate injection molding workflow:

Material Handling & Drying

Drying is critical. PC pellets must be dried (commonly 2–4 hours at ~120°C, depending on grade and dryer) to remove moisture before processing.

Melt Preparation & Injection

The dry resin is fed into the injection barrel; screw speed, back pressure, and barrel temperatures are set to create a homogeneous melt without excessive shear.

Mold Filling & Packing

The melt is injected into the mold. Proper injection speed and packing/holding pressure prevent sink marks, voids, and short shots.

Cooling & Crystallization Control

PC is amorphous, so controlling mold temperature affects surface finish and dimensional accuracy. Adequate cooling time is required but excessive cooling increases cycle time.

Ejection & Post-processing

Parts are ejected and may undergo annealing, machining, or surface finishing depending on functional and aesthetic requirements.

Quality Control

Monitor warp, dimensional tolerances, optical clarity, and mechanical properties. Process data logging helps optimize cycles and troubleshoot defects.

Advantages of Polycarbonate Molding

Mechanical Properties: Polycarbonate offers a unique combination of rigidity and toughness. While highly rigid materials are typically brittle and break upon impact, polycarbonate is both strong and durable, yet possesses exceptional toughness.

Thermal Stability: PC exhibits excellent thermal stability and a wide melting temperature range, typically between 220°C and 230°C. Furthermore, its decomposition temperature is above 300°C, and its long-term operating temperature can reach up to 120°C, demonstrating excellent heat resistance.

Flowability: Polycarbonate exhibits high melt viscosity and poor flow properties, resulting in poor injection molding processability. Increasing molecular weight increases melt viscosity. During the molding process, adjusting temperature is more effective than varying the shear rate.

Dimensional Stability: Polycarbonate exhibits excellent creep resistance, surpassing both PA and POM among engineering thermoplastics. Minimal dimensional change and cold flow deformation due to water absorption, combined with low shrinkage, ensure excellent dimensional stability.

Optical Properties: Polycarbonate's macromolecular chains are difficult to orient and crystallize, maintaining an amorphous state and exhibiting excellent transparency.

Electrical Properties: Polycarbonate molecules have low polarity, a high glass transition temperature, and low water absorption, resulting in excellent electrical insulation properties comparable to or exceeding those of PET, traditionally considered an excellent electrical insulator.

Flame Retardancy: Polycarbonate natively offers UL94 V-2 flame retardancy, eliminating the need for flame retardants. By adding a small amount of flame retardants, PC can achieve even higher fire resistance standards while maintaining excellent optical and mechanical properties, unmatched by other plastics.

Applications of Polycarbonate Molding

Electronics and Electrical: Computer cases, monitor cases, keyboards, chassis, CD players, switches, and appliance cases.

Automotive: Used in interior trims such as automotive lamps, rearview mirrors, and instrument panels, as well as exterior trims such as windows and windshields.

Construction: Used in interior trims such as automotive lamps, rearview mirrors, and instrument panels, as well as exterior trims such as windows and windshields.

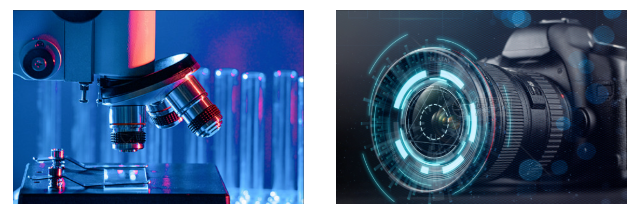

Optics: Due to its excellent transparency and high-temperature resistance, it is ideal for use in optical instruments, camera lenses, mobile phone camera lenses, and other applications.

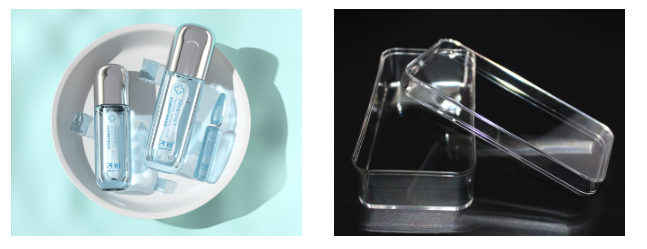

Packaging: Applications such as cosmetics, food, and pharmaceuticals.

Safety equipment: helmets, visors, protective shields

Industrial parts: machine guards, inspection windows

Challenges in Polycarbonate Molding

Moisture Sensitivity: Requires rigorous drying to avoid hydrolysis and surface defects.

High Processing Temperatures: Needs robust thermal management of barrel, nozzle, and mold.

Warp and Residual Stress: Improper cooling or packing can cause warpage and dimensional instability.

Surface Defects: Splay, flow marks, and burn marks can occur if the melt or mold temperatures are wrong.

Tooling Wear & Gate Design: PC’s higher melt temperatures may accelerate tool wear; gate and runner design must support consistent filling.

Practical Tips for Better Results

Always follow resin supplier drying recommendations and use desiccant or vacuum drying for consistent results.

Use moderate screw speeds to reduce shear heating; tune back pressure for homogeneous melting.

Optimize mold temperature: warmer molds improve flow and surface finish but increase cycle time — balance is key.

Consider annealing for stress-sensitive, optically critical parts.

Implement process monitoring (melt temperature, cavity pressure, mold temp) to catch deviations early.

Conclusion

Polycarbonate injection molding is a powerful production method for creating tough, clear, and dimensionally accurate parts. Success depends on proper material preparation (especially drying), controlled melt and mold temperatures, and careful design of gating and cooling. With the right process controls, polycarbonate can deliver reliable performance across demanding applications.

Marketing Tie-In — Why Precise Temperature Control Matters (and how your product helps)

For manufacturers optimizing polycarbonate injection molding, consistent thermal control across the melt and mold is one of the highest-impact levers for part quality and cycle efficiency. Uneven or poorly controlled temperatures cause flow imbalances, splay, burning, gate vestige issues, and increased scrap rates — all problems that raise cost and slow production.

If you are an injection molding engineer or mold shop decision maker, consider optimizing your hot runner temperature controller along with your mold temperature, nozzle design, and mold cooling system. Precise thermal control not only reduces defective product rates and rework costs but also stabilizes the yield rate of optical parts and improves overall production efficiency.

Topower, Specialized in hot runner temperature controllers in serving mold makers and injection molding factories over 12 years.

Our products include:

Modular controllers (1–16 zones)

Touchscreen multi-zone controllers (6–120 zones)

All models are CE & RoHS certified, and support OEM service. With our strong R&D and strict quality management, we are confident that we can support your hot runner projects with dependable solutions and competitive pricing.

Mobile: sales@topower-controller.com

Email: +86-13825218815

Web: www.cntopower.com