Contents1. Why cold runners drive waste in medical molding2. Eliminating Cold Runner Waste with hot ...

Hot Sprue vs Hot Runner Systems in Injection Molding

What Is the Difference Between Hot Runner and Hot Sprue?

Injection molding is one of the most efficient methods for producing plastic parts, but the method of delivering molten plastic to the mold cavities can vary. Two common systems used for this purpose are hot runner systems and hot sprue systems. Understanding their differences can help mold engineers and designers choose the most efficient solution for each project.

Understanding Plastic Flow in Injection Molding

In injection molding, plastic pellets are heated to a molten state and then injected into a mold. The molten plastic flows through channels called runners or sprues before filling the cavities. These flow channels are essential to ensure uniform distribution, reduce waste, and improve cycle time.

While traditional molds use cold runners—where plastic solidifies in the channels and must be trimmed off—modern systems like hot runners and hot sprues keep the plastic molten, eliminating or minimizing waste.

What Is a Hot Sprue System?

A hot sprue is a simple heated nozzle that directly connects the injection molding machine barrel to the cavity. It keeps the plastic inside the sprue molten using built-in heaters, allowing direct injection into the part.

How It Works

The hot sprue is installed at the center of the mold, heated by an electrical coil, and thermally insulated from the surrounding mold steel. The molten plastic passes through it, entering the cavity without forming a cold runner.

Advantages of Hot Sprue Systems

Simple structure: Only one heated nozzle, easy to install and maintain.

Cost-effective: Cheaper than a full hot runner system.

Material saving: No runner waste.

Shorter cycle times: Less time spent removing solidified runners.

Limitations of Hot Sprue Systems

Limited to single cavity or central gating.

Temperature control precision is lower compared to full hot runner systems.

Not suitable for multi-cavity molds or complex part layouts.

Hot sprue systems are commonly used in small molds, prototypes, or parts requiring simple direct gating.

What Is a Hot Runner System?

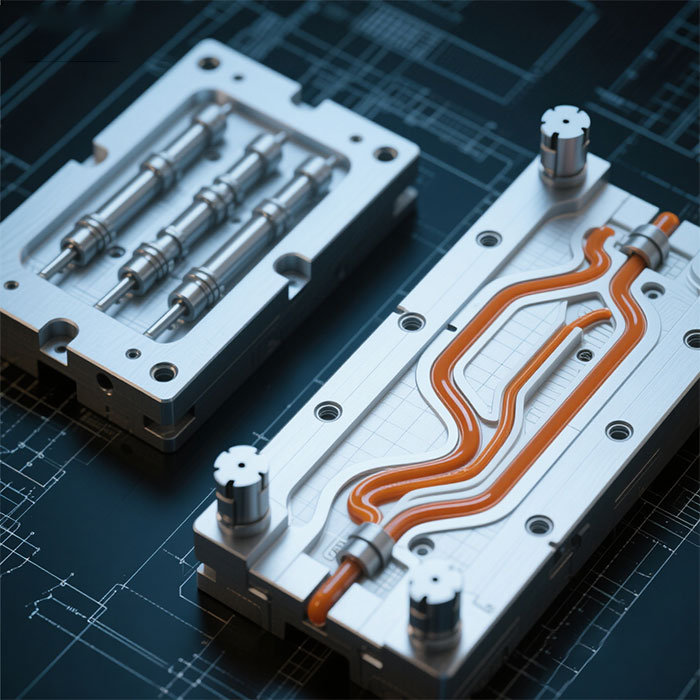

A hot runner system is a more advanced version that distributes molten plastic through multiple heated channels (called manifolds) to several nozzles, each leading to a mold cavity.

Components of a Hot Runner System

Manifold: Distributes molten plastic evenly to each nozzle.

Nozzles: Inject molten plastic into individual cavities.

Heaters and sensors: Maintain uniform melt temperature.

Temperature controller: Regulates and monitors heat for each zone.

How It Works

The plastic from the injection unit enters the heated manifold and is distributed through hot nozzles to the cavities. The entire system remains molten, ensuring smooth, consistent flow and high-quality parts.

Advantages of Hot Runner Systems

Supports multi-cavity molds.

Consistent part quality: Better temperature control prevents flow marks or short shots.

Reduced material waste: No solid runners.

Shorter cycle time: No trimming or recycling needed.

Better process control: Advanced temperature management for each zone.

Limitations of Hot Runner Systems

Higher cost: More complex design and components.

More maintenance: Requires skilled setup and monitoring.

Longer mold build time: Custom design for each application.

Hot runner systems are ideal for high-volume production, complex parts, and when material savings are a priority.

Key Differences Between Hot Sprue and Hot Runner Systems

| Metric | Goal | Tool |

| Organic Traffic | +20% in 3 months | Google Analytics |

| Keyword Ranking | Top 10 for “hot runner vs hot sprue” | Google Search Console |

| CTR | >4% from organic search | Search Console |

| Bounce Rate | <50% | Analytics |

| Inquiries via CTA | 15% | CRM / Contact Form |

When to Choose Each System

Choose a Hot Sprue System when simplicity, low cost, and single-cavity production are your priorities. It’s an excellent choice for testing, small runs, or smaller components.

Choose a Hot Runner System when you need high productivity, consistent quality, or are working with expensive engineering plastics. Despite the higher initial cost, it saves money long-term through material savings and faster cycles.

Conclusion

Both hot runner and hot sprue systems aim to keep the plastic molten during injection, but they serve different purposes. A hot sprue is simple and cost-effective for single-cavity applications, while a hot runner system offers high precision and efficiency for large-scale manufacturing.

Choosing the right system depends on your production scale, mold complexity, and budget. For many manufacturers, investing in a reliable temperature control system can make a significant difference in achieving stable, efficient, and high-quality production.

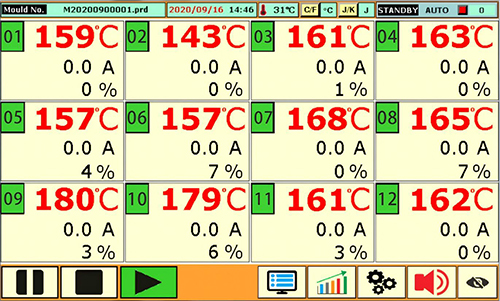

Power Your Hot Runner System with CNTOP

If you are using or planning to upgrade your hot runner system, temperature control plays a critical role in performance and part quality. CNTOP offers advanced Hot Runner Temperature Controllers that provide:

Precise multi-zone temperature control for consistent melt flow.

Smart touchscreen interface for easy monitoring and adjustment.

Reliable safety protection and stable performance for long-term use.

Custom solutions tailored to your mold requirements.

Explore more here: CNTOP Hot Runner Temperature Controller

Enhance your injection molding performance with better temperature accuracy, energy efficiency, and productivity — all powered by CNTOP.