Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

Open-Loop vs. Closed-Loop Temperature Control: What’s Best for Molders?

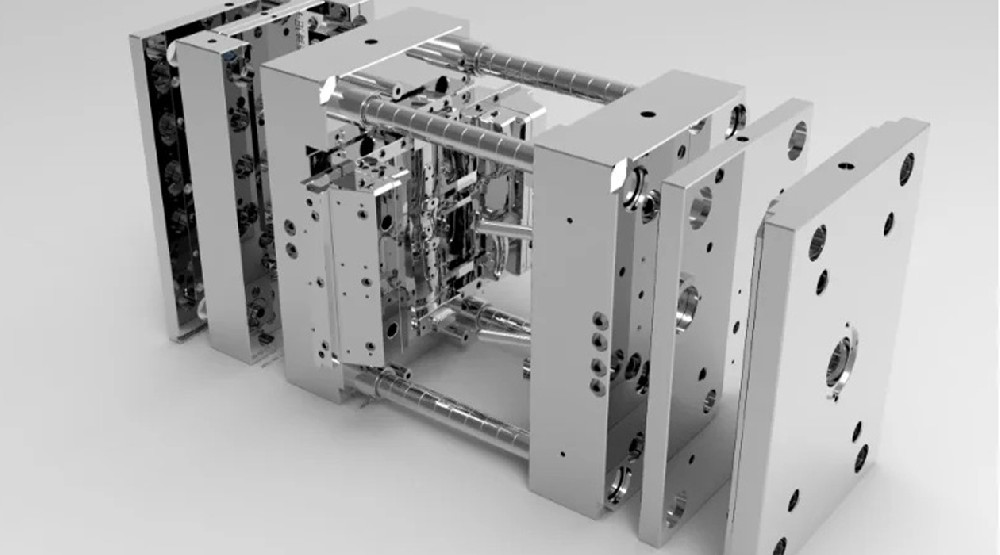

In modern injection molding, temperature stability is one of the most critical factors that determines part quality, cycle time, scrap rate, and overall process efficiency. And when it comes to temperature management—especially in hot runner systems, manifold zones, and multi-cavity molds—molders often face a key question:

Should You Use Open-loop or Closed-loop Temperature Control?

Both control methods have been widely used in the industry, but they differ significantly in terms of accuracy, stability, and long-term production performance. This article breaks down how each system works, their advantages and limitations, and how molders can choose the best solution for their applications.

What Is Open-Loop Temperature Control?

Open-loop temperature control is the simplest method for heating. The controller outputs power based on a preset percentage or time cycle—without measuring the actual temperature and adjusting accordingly.

How It Works

Controller delivers a fixed heating output.

No thermocouple feedback is used.

The system cannot automatically correct for environmental or load changes.

Advantages

Low cost

Simple wiring & setup

Fewer components minimize maintenance

Suitable for applications with wide temperature tolerances

Limitations

No correction for:

ambient temperature changes

heater wear or drift

varying thermal loads

Temperature stability is difficult to maintain

Risk of inconsistent part quality and higher scrap

Best for:

Single-cavity molds, non-critical parts, prototyping, or where temperature variation does not affect final product performance.

What Is Closed-Loop Temperature Control?

Closed-loop (feedback) control is the industry-standard method for precision molding and hot runner applications.

It uses thermocouples or RTDs to continuously monitor the actual temperature and adjust heater output in real time.

How It Works

Temperature sensor reads real-time data

Controller processes feedback with a PID algorithm

Power is increased or reduced to maintain the setpoint

Adjustments occur continuously during production

Advantages

High accuracy and precision

Consistent part quality

Stable operation even with large thermal fluctuations

Ideal for:

multi-cavity molds

high-temperature engineering plastics

color-sensitive resins

cosmetic parts

Limitations

Higher cost compared to open-loop control

Requires more wiring and components

Slightly more complex commissioning

Best for:

Hot runner systems, zones requiring tight temperature uniformity, and applications where quality consistency is critical.

Open-Loop vs Closed-Loop: Key Differences at a Glance

| Factor | Open-Loop | Closed-Loop |

| Accuracy | Low–moderate | High, ±0.5°C possible |

| Stability | Sensitive to environment & load changes | Automatically compensates in real time |

| Sensor Required | No | Yes (TC or RTD) |

| Cost | Lower | Higher |

| Ideal Use | Simple molds, low tolerance | Hot runner, multi-cavity, precision molding |

| Scrap Risk | Higher | Much lower |

| Commissioning | Easy | Moderate |

Which System Should Molders Choose?

Choose Open-Loop If:

Your mold has wide tolerance parts

You are running simple or low-cost applications

Consistency and aesthetics are not critical

You want the lowest initial investment

Choose Closed-Loop If:

You run multi-cavity molds

You use hot runner systems

Parts require high dimensional or cosmetic consistency

You mold high-value or temperature-sensitive plastics

You want long-term process stability and lower scrap

For most modern molding operations—especially hot runner systems—closed-loop control is the clear winner.

Why Closed-Loop Control Delivers Higher ROI

Even though closed-loop systems cost more upfront, they quickly pay back through:

Reduced scrap rate

Fewer operator adjustments

Shorter start-up time

More consistent cycles

Better color stability for aesthetic parts

Improved repeatability across production shifts

When molding expensive materials or running 8–32 cavity molds, closed-loop temperature control often saves thousands of dollars per month in material waste and downtime.

How to Select the Right Temperature Controller

When choosing a closed-loop controller for your molding application, look for:

PID Algorithms with Autotuning

Helps optimize performance and minimize overshoot during startup.

Multi-Zone Control Capability

Essential for hot runner systems, where each nozzle requires individual feedback.

Accurate Thermocouple Support

Type J/K thermocouples are common—ensure compatibility.

Alarm & Protection Features

Over-temperature alarm

Open/short sensor detection

Heater burnout detection

Data Logging and Connectivity

Ethernet/Modbus support is valuable for Industry 4.0 environments.

Conclusion

Both open-loop and closed-loop temperature control systems have their place in injection molding. However, as industry standards shift toward higher precision, automation, and multi-cavity tooling, closed-loop control has become the preferred solution for most molders.

If your goal is stable processes, consistent part quality, and reduced scrap, closed-loop temperature control is the ideal choice.