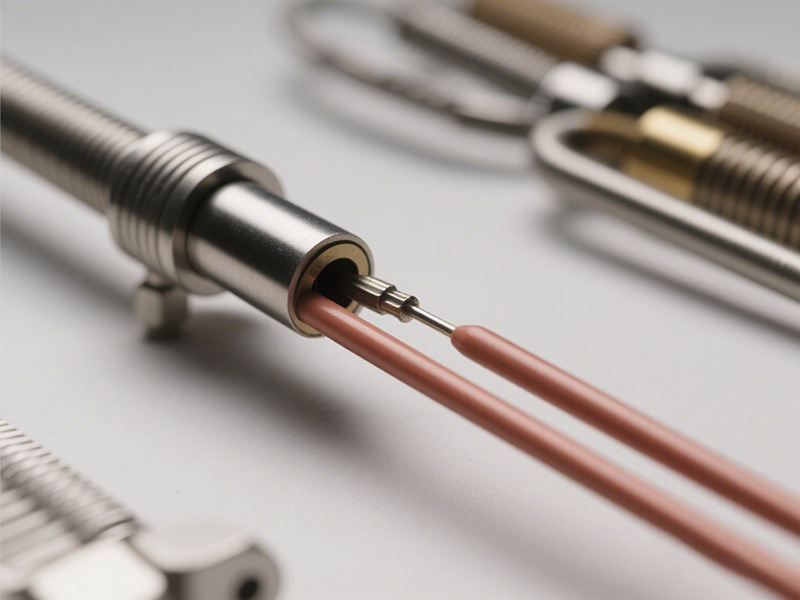

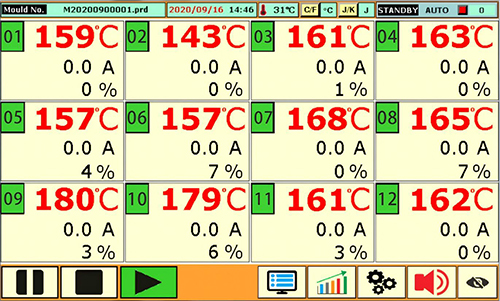

In modern injection molding, precision is not optional—it is fundamental. At the center of th...

How to Diagnose and Fix Thermocouple Failures: A Practical Troubleshooting Guide

Introduction

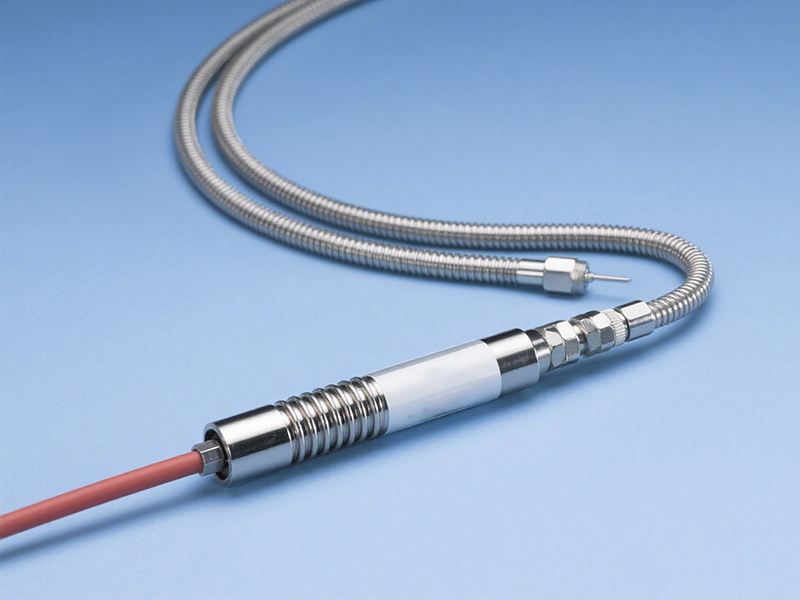

Thermocouples are trusted for industrial temperature measurement because they are rugged, fast, and reliable. However, harsh conditions—vibration, moisture, corrosion, and wiring issues—can cause inaccurate or unstable readings.

This guide provides a complete, field-ready method to diagnose and solve thermocouple faults. It integrates common industrial failure modes such as drift, moisture intrusion, poor contact, installation errors, and compensation-wire mismatches. Use this article as a troubleshooting manual to restore accurate measurement and reduce process downtime.

Why Thermocouple Type Matters

Before troubleshooting, always confirm the thermocouple type (K, J, T, E, S, R, B).

Using incorrect extension cables, mismatching instrument settings, or exposing certain types to inappropriate atmospheres can generate large reading errors.

Common Thermocouple Symptoms and Their Root Causes

Below is a practical breakdown of typical symptoms and what usually triggers them.

Reading Lower Than Actual Temperature (Indication Too Low)

Possible causes

Sensor degradation or oxidation at the hot junction

Over time, the tip may deteriorate or become contaminated, leading to lower EMF output.Moisture inside the protection tube or insulation

Damp insulation increases leakage paths and reduces the signal.Dust, debris, or metal particles inside the connection box

Conductive contaminants can create partial short circuits.High circuit resistance

If wiring resistance exceeds typical limits (often around 10–15 Ω), signal loss increases.Compensation cable issues

Moisture intrusion or short circuits between wire and protection tube.Incorrect extension wire type

Using a mismatched grade or non-thermocouple wire shifts the measured value.Shallow insertion depth

The junction must be fully inside the active temperature zone.Cold junction too warm or unstable

High ambient temperature around terminals shifts the reference temperature.

How to fix

Replace or re-weld the junction if the sensing tip is damaged.

Dry the insulation, sheath, and junction box thoroughly.

Clean out the terminal area and ensure the outlet points downward to avoid moisture entry.

Measure circuit resistance; replace wiring if excessive.

Replace compromised compensation cables and improve waterproofing.

Ensure extension wires match the thermocouple type.

Increase insertion depth (typically ≥ 8 times the sheath diameter).

Move the cold junction to a cooler and stable location using proper compensation cable.

Reading Higher Than Actual Temperature (Indication Too High)

Possible causes

Instrument set to the wrong thermocouple type

Extension wire mismatched to the sensor

Sensor positioned too close to the heat source, not in the representative zone

How to fix

Reconfigure instrument input type

Install correct matching compensation wire

Adjust the probe position to a more representative location

Reading Is Unstable or Fluctuating

Possible causes

Loose terminal screws

Intermittent insulation breakdown causing periodic shorting or grounding

Excessive vibration causing unstable contact

Electromagnetic interference (EMI) from power cables, motors, or VFDs

How to fix

Tighten all terminals and clean contact surfaces

Identify insulation failure points and replace damaged components

Secure the probe or add vibration-damping brackets

Add shielding, grounding, or reroute wiring away from power lines

No Signal Output / Sensor Not Responding

Possible causes

Short circuit in the measuring loop

Broken wire or open circuit along the cable

Loose terminals

Completely burned or melted thermocouple tip

How to fix

Re-insulate or replace shorted sections

Perform continuity tests to locate open circuits

Tighten all terminals

Replace the thermocouple if the junction has failed

Step-by-Step Troubleshooting Procedure

Below is a structured, field-tested method combining practical checks with professional diagnostics.

Initial Inspection

Verify safety and isolate the sensor.

Inspect for mechanical damage—bent probes, crushed cable, cracked insulation.

Check for contamination—dust, metal shavings, fluids inside the connection box.

Confirm proper installation depth—too shallow results in the wrong temperature zone.

Electrical Tests

Continuity Test

Use a multimeter to verify the circuit is not open or shorted.

Loop Resistance Test

Excessive resistance suggests corrosion, poor connections, or degraded wiring.

mV Output Test

Compare measured mV with standard thermocouple tables to detect drift or offset.

Cold Junction Verification

Ensure CJC sensor is functioning and ambient temperature is stable.

Wiring & Cable Validation

Check polarity (+ / – must not be reversed).

Ensure extension cables match the thermocouple type.

Look for moisture intrusion causing leakage paths.

Ensure proper shielding and routing away from power cables.

Substitution Testing

To differentiate sensor failure from instrument failure:

Replace the thermocouple with a known-good probe.

Or connect a thermocouple simulator to the controller.

If the controller reads correctly with a simulator, → sensor or wiring is faulty.

Preventive Maintenance Tips

To avoid future failures:

Keep terminal boxes dry and downward-facing.

Inspect regularly for signs of corrosion or thinning of the sheath.

Avoid routing thermocouple cables with high-current lines.

Use appropriate protective sheaths for corrosive or high-temperature environments.

Establish a periodic calibration schedule, especially for high-temperature processes.

Summary

Thermocouples are reliable but can fail due to moisture, wiring errors, poor installation, or sensor degradation. By combining quick visual inspections, electrical checks, proper wiring validation, and calibrated replacement probes, you can diagnose most failures quickly and restore stable temperature measurement.

CNTOPower provides professional temperature control solutions designed for hot runner systems and industrial molding applications. If you need stable, precise temperature control with multi-zone capabilities, explore our industrial temperature controller solutions.