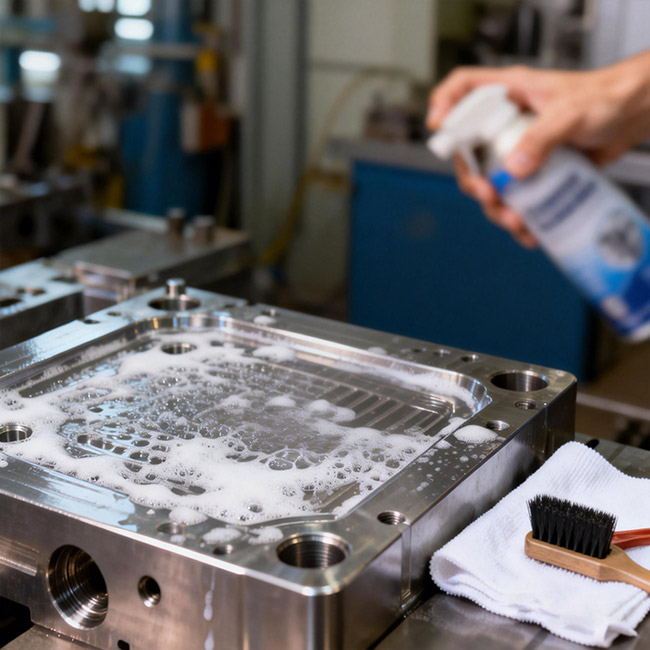

Injection Mold Maintenance and Care

Key Practices to Extend Mold Life and Ensure Stable ProductionInjection molds are core production assets in plastic injection molding. Their condition directly affects product quality, production effi...

Comprehensive Guide: The Role of Temperature Control Switches in Hot Runner Systems

In injection molding, temperature stability is not a luxury—it is a requirement. Even minor temperature fluctuations inside a mold can lead to defects such as short shots, material degradation, strin...

Injection Molding vs 3D Printing: Materials, Strength, Heat Resistance & Surface Finish

IntroductionWhen choosing a plastic manufacturing process, materials and performance often matter more than speed or initial cost. Two of the most widely used methods today—injection molding and...

How to Select the Best Plastics for Injection Molded Automotive Parts

Choosing the right material is one of the most critical steps in automotive plastic injection molding. From interior trims to structural brackets and under-the-hood components, every resin direc...

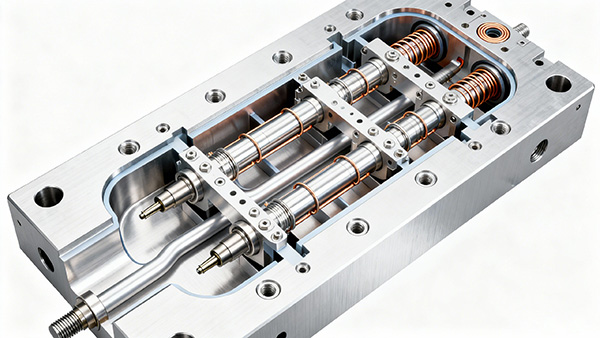

A Complete Guide to Hot Runner Molds: Advantages, Disadvantages, Key Technical Factors, and Application Fields

IntroductionAs injection molding technology continues to advance, hot runner molds have become a mainstream solution in global manufacturing. From thin-wall packaging to medical devices and consu...

Hot Runner vs Cold Runner: Which Injection Molding System Is Best for Automotive Components?

Automotive manufacturers rely heavily on plastic injection molding to produce lightweight, durable, and cost-efficient components. From interior trims and dashboard modules to clips, connectors, and f...

How To Choose The Right Material For Plastic Injection Molding(ABS、PP、PE、PC、PA、PBT)

Choosing the right material for plastic injection molding is one of the most important factors that determine the performance, durability, cost, and manufacturability of your parts. Whether you a...

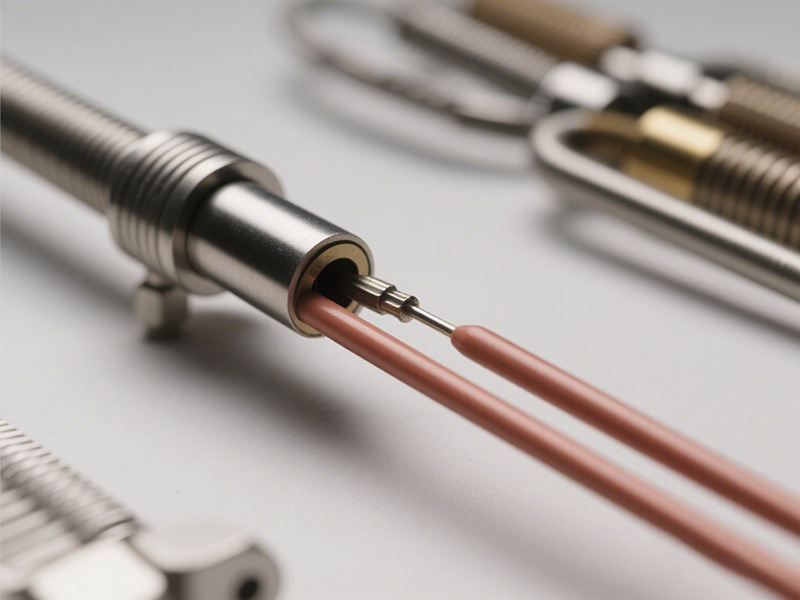

How to Diagnose and Fix Thermocouple Failures: A Practical Troubleshooting Guide

IntroductionThermocouples are trusted for industrial temperature measurement because they are rugged, fast, and reliable. However, harsh conditions—vibration, moisture, corrosion, and wiring issues—...