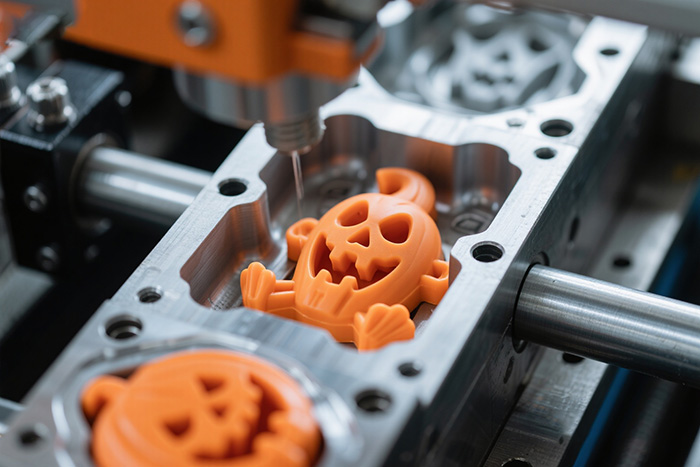

How Has Plastic Injection Moulding Contributed to Your Halloween Products?

IntroductionEvery Halloween season, shelves fill up with colorful, creative, and spooky products — from plastic Halloween pumpkins to Halloween plastic cups and plastic Halloween buckets. B...

Differences Among Injection Molding, Blow Molding, Blister Molding, and Extrusion Molding: A Complete Comparison Guide

When it comes to plastic manufacturing, choosing the right forming process is essential for achieving the perfect balance between quality, cost, and production efficiency. The four most widely used pl...

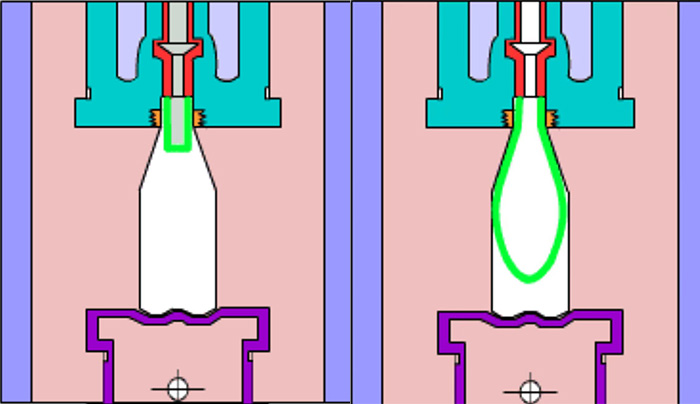

Everything You Need to Know About PET Bottles and Their Manufacturing Process

IntroductionEver wondered how a simple PET bottle goes from tiny resin pellets to the bottle you drink from every day?The process behind PET bottle manufacturing is a combination of chemistry, pr...

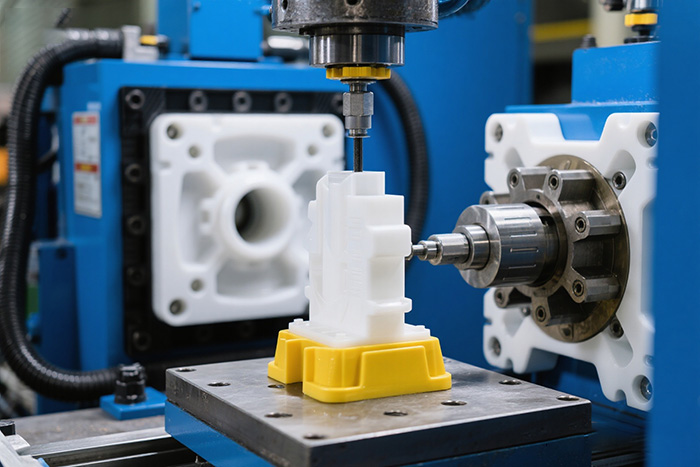

What Is HDPE Injection Molding? A Complete Beginner’s Guide

High-density polyethylene (HDPE) injection molding is one of the most common and cost-effective ways to produce durable, lightweight plastic parts at scale. This guide gives beginners a clear, practic...

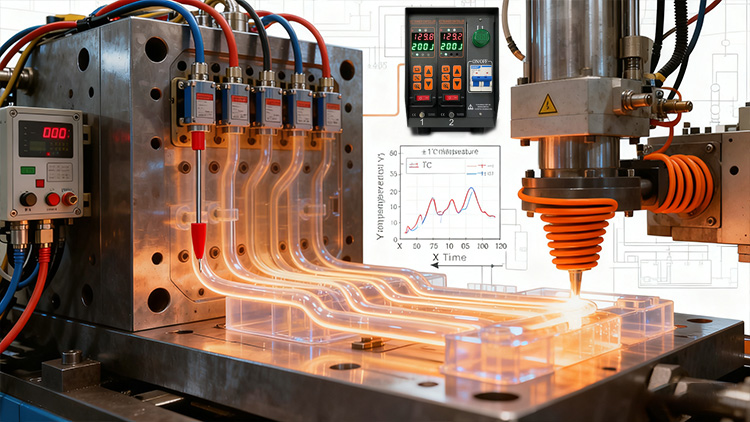

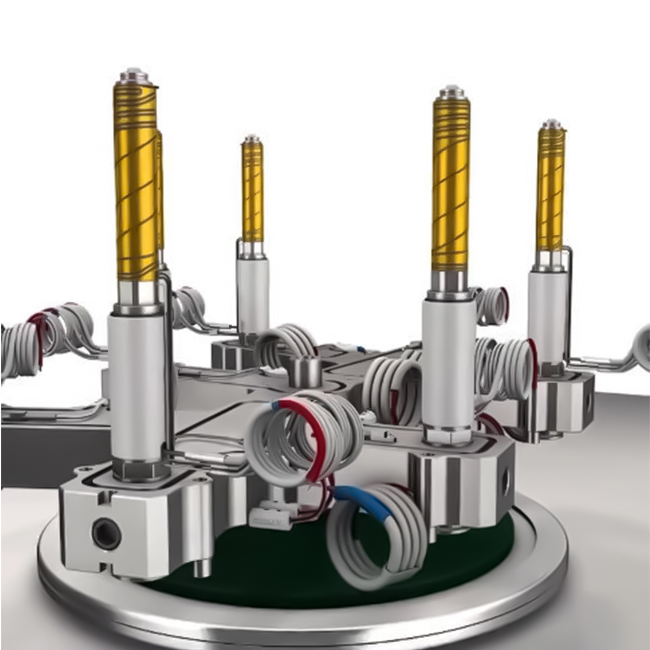

Why More and More Products Use Hot Runner Injection Molding?

IntroductionIn modern manufacturing, the demand for efficiency, precision, and sustainability is stronger than ever. Traditional cold runner systems are gradually being replaced by hot runner injectio...

What Is The Difference Between Semi Hot Runner And Full Hot Runner?

In modern injection molding, efficiency and precision are critical. Among the many mold design choices, hot runner and semi-hot runner (micro semi-hot runner) systems represent two dist...

Hot Sprue vs Hot Runner Systems in Injection Molding

What Is the Difference Between Hot Runner and Hot Sprue?Injection molding is one of the most efficient methods for producing plastic parts, but the method of delivering molten plastic to the mold cavi...

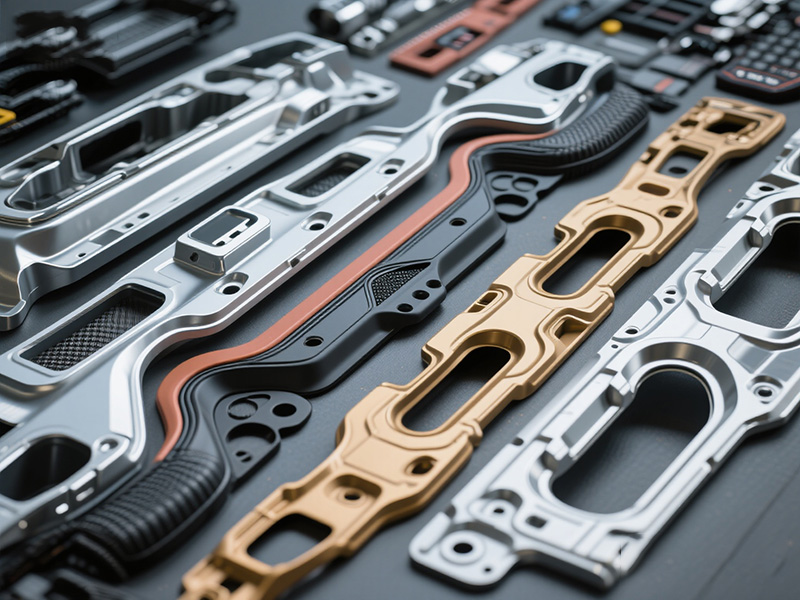

Multi-Material Overmolding for Automotive Applications: Techniques & Best Practices

In the evolving world of automotive manufacturing, overmolding (or multi-material injection molding) has become an increasingly vital technique to achieve high integration, improved performance, and a...