Everyday Plastic You Encounter — But Do You Really Understand It?Have you ever noticed a small tria...

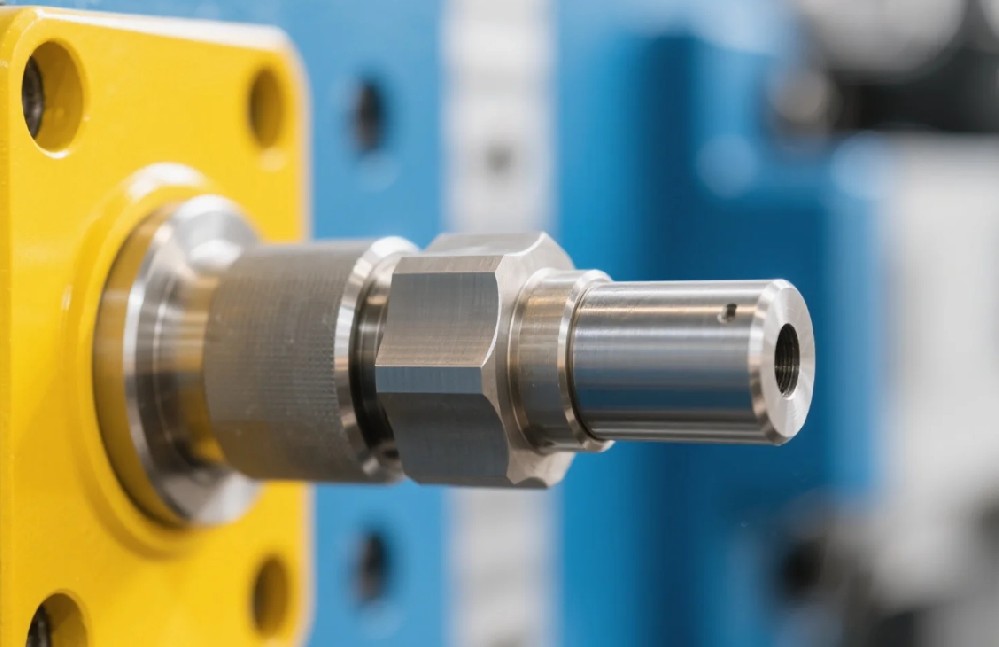

How to Fix Common Nozzle Problems in Injection Molding

Nozzle problems in injection molding, particularly with the injection molding nozzle, can hurt production and quality. For example, defects in the injection molding nozzle may cause daily losses of 19.34 RMB. Companies might spend up to 3.36 million RMB yearly on repairs related to these nozzles. Additionally, the nozzle flow can take up to 2400 psi pressure, which can lead to pressure loss and product defects. Fixing these problems with the injection molding nozzle is important to reduce waste and improve efficiency. It also helps keep product quality steady. By solving issues with the injection molding nozzle, you can protect your work process and avoid expensive delays.

You will know about:

Check for leaks by keeping nozzle pressure between 4 to 10 tons. Make sure the nozzle tip and sprue bushing line up to avoid wasting materials.

Stop drooling by setting the melt temperature to fit your material. Use a nozzle with a shut-off valve to control plastic flow better.

Check and take care of your nozzle parts often. Watch for wear or misalignment to prevent delays and keep products high quality.

Use the same nozzle sizes on all machines to avoid mismatches. This makes maintenance easier and keeps product quality steady.

Teach workers how to use and care for injection molding machines. Trained workers can find problems early, helping things run smoothly and making better products.

Identifying Common Injection Molding Nozzle Problems

Leaks

Leaks are a frequent problem with injection molding nozzles. They happen when melted plastic escapes during the injection process. This can waste material, damage equipment, and ruin products.

Here are some reasons for nozzle leaks:

Not enough nozzle pressure lets plastic leak out. Machines need 4 to 10 tons of pressure to seal properly.

Too much contact area between the nozzle and sprue bushing can cause trouble. A smaller contact ring, like 3/8-inch or 1/4-inch, works better.

Misaligned nozzle tips and sprue bushings are another issue. Matching their shapes can stop leaks and improve results.

Problem Description | Cause/Issue Description | Solution Description |

|---|---|---|

Nozzle Leaks | Low nozzle contact pressure | Increase contact pressure (4 to 10 tons) |

Excessive contact area | Use a smaller contact ring (3/8-in. to 1/4-in.) | |

Misalignment of components | Align nozzle tip and sprue bushing radii |

Sealing the nozzle tip tightly against the sprue bushing is key. Without this, leaks can raise costs and lower product quality.

Nozzle Drooling

Drooling happens when melted plastic drips from the nozzle. This can occur before or after the injection process. It wastes material and creates defects in parts. High melt temperature often causes drooling. Lowering the temperature to the right level for your material can fix this.

Another reason for drooling is a poorly designed nozzle. A bad shut-off valve or wrong tip shape can fail to control plastic flow. Using a nozzle with a better shut-off system can reduce drooling and improve results.

Misalignment

Misalignment between the nozzle tip and sprue bushing causes big problems. It can lead to leaks, nozzle tip damage, or issues like short shots and stuck runners.

Bad misalignment can also cause color streaks or other flaws in parts. Keeping these parts aligned is important for quality and to avoid wear on equipment.

To fix misalignment, check that the nozzle tip and sprue bushing match in shape. Regular checks and adjustments can save time and prevent costly repairs.

Size Mismatches

When the nozzle tip and sprue bushing don't fit, problems happen. These size mismatches can cause leaks, uneven flow, or equipment damage. Such issues may lead to bad products and wasted time.

One reason for mismatches is using a nozzle tip with the wrong radius. If the nozzle tip is too big, it won't seal well. This lets melted plastic leak out, wasting material. If the nozzle tip is too small, it won't have enough contact to seal tightly.

To fix this, measure both the nozzle tip and sprue bushing. Use tools like calipers to get exact sizes. Compare these measurements to the machine's specifications. If they don't match, replace the parts with ones that fit correctly.

Tip: Always check if your nozzle tip and sprue bushing fit before starting. This quick step can save time and avoid mistakes.

You can also standardize the sizes of your nozzles and sprue bushings. This makes mismatches less likely and maintenance easier. By matching sizes properly, you can make your process smoother and keep product quality high.

Causes of Injection Molding Nozzle Problems

Low Contact Pressure

When the nozzle and sprue bushing don't press tightly, plastic leaks. This happens if the pressure is too low. A weak seal lets melted plastic escape, wasting material. It can also cause defects in your products. To fix this, make sure the machine uses enough pressure. Usually, 4 to 10 tons of pressure works best. Check the contact area often to spot problems early.

Excessive Melt Temperature

If the melt temperature is too high, problems can occur. Hot plastic becomes too runny and hard to control. This can lead to leaks, drooling, or nozzle damage.

High temperatures may also ruin the product. Issues like warping, discoloration, or weak parts can happen.

These problems slow production and hurt product quality.

Set the temperature based on the material's needs. Watch the temperature during molding to keep it steady. This helps avoid defects and keeps things running smoothly.

Radius Mismatch

If the nozzle tip and sprue bushing don't match, trouble starts. Uneven pressure can cause leaks or blow-back. This wastes material and harms equipment.

Precision is very important. If the nozzle tip or sprue bushing is the wrong size, leaks happen.

For example, using a ¾-inch nozzle tip with a ½-inch sprue bushing won't work well.

Measure both parts carefully to ensure they fit correctly. Matching sizes keeps the seal tight and improves efficiency.

Incorrect Setup or Damage

Wrong setup or damage can harm how your nozzle works. If parts are not put in right, they may not line up. This can cause leaks and waste material. It also lowers the quality of your products. Follow the correct steps and use proper tools to avoid this.

Using the wrong tools can break nozzle parts. For example, pushing too hard can bend or damage them. Always pick tools made for your machine to avoid mistakes. Also, not using the right torque can weaken part connections. This makes them more likely to fail.

Temperature changes during setup can also cause problems. If the nozzle heats unevenly, it may not stay aligned. This can break seals and lead to leaks. Keep the temperature steady to avoid these issues. Watching the temperature helps the nozzle work better.

Write down any problems you see during maintenance. If leaks or damage happen often, check your setup steps. Fixing these small issues early can stop bigger problems later. Keeping records helps you find and fix patterns.

By setting up correctly and fixing wear early, your nozzle lasts longer. This saves time, reduces waste, and keeps product quality high.

Troubleshooting and Fixing Injection Molding Nozzle Issues

Adjusting Contact Pressure

Contact pressure helps the nozzle seal tightly to the sprue bushing. If the pressure is too low, melted plastic can leak out. This wastes material and causes problems. Increasing the pressure can stop leaks and improve performance.

A new nozzle tip design works well to fix leaks and stringing. It reduces the contact area, which increases sealing pressure. This stops blowback and prevents leaks. Tests show that adjusting pressure this way improves results.

To fix pressure issues, check your machine's settings. Make sure it applies 4 to 10 tons of pressure. If leaks continue, inspect the nozzle tip design. You might need a better one for stronger sealing. Regularly checking pressure can save time and keep quality high.

Aligning Components

The nozzle tip and sprue bushing must line up correctly. Misalignment can cause leaks, short shots, or damage to parts. It may also create defects like streaks or bubbles in products.

To align them, inspect both the nozzle tip and sprue bushing. Their shapes should match perfectly. A bad fit can block the flow and cause problems like sticking or uneven plastic. Use tools like calipers to measure and ensure they fit together.

Tip: Check alignment often to avoid equipment damage. Inspect these parts before every production run.

If alignment is still off, replace any damaged parts. Proper alignment improves efficiency and reduces product defects.

Replacing Damaged or Worn Parts

Worn or damaged parts can harm how the nozzle works. Over time, heat, pressure, or rough handling can wear out parts. This can lead to leaks, uneven flow, or poor sealing.

Look for signs of damage like cracks, warping, or discoloration. If leaks or problems happen often, replace the worn parts. Use high-quality replacements that fit your machine's specifications.

Note: Follow the manufacturer's instructions when installing new parts. Wrong installation can cause more issues and shorten the part's life.

Replacing damaged parts quickly avoids delays and keeps quality steady. Fixing wear early helps your nozzle last longer and keeps production running smoothly.

Fixing Melt Temperature Settings

Setting the right melt temperature is very important. If it's too high or low, problems happen. These include bad parts, wasted material, and broken equipment. Adjusting the temperature helps the plastic flow well and fill the mold.

Why Melt Temperature Is Important

Melt temperature affects how good the molded parts are. If it's too high, the plastic gets too runny. This can cause dripping, bending, or color changes. If it's too low, the plastic won't flow right. This leads to incomplete parts or gaps. Both problems waste money and time.

Studies show that even melting makes better parts. Barrel heat and screw speed are key to this. Balancing these keeps the melt smooth and avoids defects. Troubleshooting guides suggest checking melt and mold heat if parts look wrong. This helps control size and shape.

Steps to Fix Melt Temperature

Know Your Material's Needs

Each material has a best melt temperature. Check its datasheet for the right range.Set Barrel Heat Zones

Split the barrel into zones. Heat each zone step by step. Start cooler at the feed zone and get hotter near the nozzle.Adjust Screw Speed

Fast screw speeds make too much heat. Slow speeds may not melt the plastic enough. Match the screw speed to the barrel heat.Test and Change

Make a test part and check for problems like bending or gaps. Change the temperature a little and test again until the part looks good.

Tip: Use a special thermometer to check the real melt temperature. This makes sure the machine settings are correct.

Mistakes to Watch Out For

Not Checking Often: Skipping temperature checks can cause bad results.

Changing Too Much: Big temperature changes can make new problems. Adjust slowly.

Forgetting Material Changes: Using new plastic without changing settings can ruin parts.

By fixing the melt temperature, you can make better parts, save material, and protect your equipment.

Preventative Measures for Injection Molding Nozzle Problems

Regular Maintenance and Inspection

Taking care of your injection molding nozzle is very important. Regular checks can stop problems before they get worse. This helps avoid expensive repairs and keeps product quality steady.

Here are some easy tips to maintain your nozzle:

Use your nose to find leaks. A burning plastic smell often means trouble.

Pay attention to strange machine noises. These might mean parts like the hydraulic pump are not working right.

Maintenance Tip | Description |

|---|---|

Smell Detection | Sniff for burning plastic to catch possible nozzle leaks early. |

Hearing Checks | Listen for odd sounds that may signal machine problems. |

Focus inspections on key areas like alignment and injection stops. Good alignment stops leaks and blowback. Adjusting injection stops keeps the nozzle at the right height.

Inspection Item | Purpose |

|---|---|

Nozzle Alignment | Stops resin leaks and blowback, which can cause molding issues. |

Injection Stops Adjustment | Keeps the nozzle aligned and at the correct height. |

By following these steps, you can make your nozzle last longer and improve production.

Proper Material Drying

Drying materials the right way is crucial for nozzle performance. Wet materials can cause problems like dripping and weaker plastic. These issues hurt both the nozzle and the final product.

Issue | Effect on Nozzle | Recommended Action |

|---|---|---|

Moisture presence | Dry materials as per recommended times and temperatures. |

Always dry materials based on the manufacturer's instructions. Follow the suggested drying time and temperature for your material. This ensures smooth plastic flow and proper mold filling.

Tip: Get a good drying system to keep materials consistent. This small investment saves time and reduces waste over time.

Standardization of Nozzle Sizes

Using the same nozzle sizes on all machines makes work easier. It also lowers the chance of mismatched parts. Matching sizes prevents leaks and uneven plastic flow.

Start by measuring the nozzle tip and sprue bushing on each machine. Use tools like calipers to check their sizes. Replace any parts that don’t match the standard size.

Standardizing sizes also helps with spare parts. When all parts are the same size, you save money and reduce repair delays.

Note: Standardizing nozzle sizes boosts efficiency and keeps product quality consistent. This ensures every part meets high standards.

Training Operators on Best Practices

Teaching operators the right way to work is very important. It helps keep the injection molding process running smoothly. Trained workers can use machines better and spot problems early. This saves time and money by avoiding mistakes or delays.

Why Training Matters

Good training gives operators the skills to work safely. They learn how the injection molding process works and how to avoid risks. For example, they can notice wear on the nozzle or alignment problems before they get worse.

Training also helps operators understand the machines and materials. They can adjust settings like melt temperature or pressure to improve results. This lowers the chance of defects like leaks or drooling and keeps product quality steady.

Benefits of Training

Training workers has many advantages for production:

Less wasted material

Faster and smoother operations

Fewer machine breakdowns

Happier and more confident workers

When workers feel skilled, they take pride in their jobs. This makes the workplace safer and more productive.

Key Areas to Focus On

Focus on these important topics during training:

Safety Rules

Teach workers how to stay safe around machines. Show them how to handle hot materials and high-pressure systems.Using Machines

Train workers to operate and check equipment. They should know how the nozzle works and how to adjust settings.Fixing Problems

Show workers how to solve common issues. For example, teach them to fix alignment or adjust melt temperature to stop defects.Handling Materials

Teach workers to dry and store materials correctly. This prevents moisture problems that can cause weak parts or dripping.

Tips for Effective Training

Use both classroom lessons and hands-on practice.

Give simple guides for using and fixing machines.

Let workers ask questions and share ideas. This helps everyone learn better.

Offer refresher courses often to keep skills updated.

By training your team well, you can make injection molding more reliable. Workers will handle problems better, care for equipment, and create high-quality products every time.

Fixing nozzle problems helps production run smoothly and improves product quality. Spotting issues like leaks or misalignment early saves time and reduces waste. Regular maintenance and troubleshooting stop expensive breakdowns from happening.

Pro Tip: Train workers and use standard nozzle sizes to keep things running well.

Use these ideas to make your work better. You’ll have fewer mistakes, spend less money, and make customers happier. Start using these tips now for long-term success in your work.

FAQ

What causes nozzle leaks in injection molding?

Nozzle leaks happen when pressure is too low or parts don’t fit. Misaligned or mismatched nozzle tips and sprue bushings can also cause leaks. Check these parts often and fix alignment or pressure issues to stop leaks.

How can you prevent drooling from the nozzle?

Drooling happens when melted plastic drips from the nozzle. Lower the melt temperature to match the material’s needs. Use a nozzle with a good shut-off valve or better tip design to control the flow.

Why is nozzle alignment important?

Nozzle alignment keeps plastic flowing smoothly and stops problems like leaks or damage. Misalignment can ruin parts by causing streaks, bubbles, or other defects. Fixing alignment helps make better products.

How do you fix a radius mismatch between the nozzle tip and sprue bushing?

Use calipers to measure the nozzle tip and sprue bushing sizes. Replace parts that don’t fit the machine correctly. Standardizing nozzle sizes across machines can help avoid mismatches.

What are the benefits of regular nozzle maintenance?

Regular maintenance stops leaks and keeps the nozzle working longer. It also helps make better products and reduces repair costs. Checking the nozzle often keeps production running smoothly.